Abstract

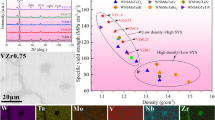

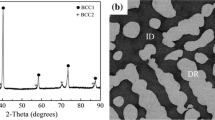

The present investigation aims to examine the impact of incorporating rare earth elements (Dy and Nd) into dual-phase hexagonal close-packed (HCP) ternary refractory medium-entropy alloy HfTiZr. The HfTiZr, (HfTiZr)98Dy2, and (HfTiZr)96Dy2Nd2 alloy exhibit yield strength of 356.95, 424.53, and 458.81 MPa, respectively, and ductility of 8.5, 11, and 10% elongation, respectively. A comparative investigation is conducted to analyze the microstructure and mechanical properties of HfTiZr, (HfTiZr)98Dy2, and (HfTiZr)96Dy2Nd2. With the addition of Dy and Nd, the alloy exhibits an increase in BCC phase fraction with basket weave morphology. The micro indentation technique was employed to determine the average hardness values of 6.35, 7.58, and 8.59 GPa for the materials HfTiZr, (HfTiZr)98Dy2, and (HfTiZr)96Dy2Nd2, respectively. The observed rise in hardness can be attributed to the concurrent increase in solid solution hardening, which arises from the introduction of larger atomic radii, leading to an increase in lattice distortion. The present study presents a novel approach to include rare earth elements into ternary refractory alloys, thereby facilitating the formation of a dual-phase structure and leading to improved mechanical properties.

Similar content being viewed by others

References

Sharma A S, Yadav S, Biswas K, and Basu B, Mater. Sci. Eng. R Reports 131 (2018) 1.

Gurao N P, and Biswas K, Curr. Sci. 118 (2020) 1520.

Garcia Filho F D C, Ritchie R O, Meyers M A, and Monteiro S, N. J. Mater. Res. Technol. 17 (2022) 1868.

Raturi, A., Aditya C, J., Gurao, N. P. & Biswas, K. J. Alloys Compd. 806, 587 (2019).

Gu D, et al., Mater. Sci. Eng. A 879 (2023) 145217

Duan J-M, Shao L, Fan T-W, Chen X-T, and Tang B-Y, Int. J. Refract. Met. Hard Mater. 100 (2021) 105626

Li X, Liu C, Wang J, and Zhang C, Mater. Today Commun. 28 (2021) 102627

Xue H, et al., Mater. Charact. 187 (2022) 111874

YAN, W. Gao, Wang, H. ming, Tang, H. bo, Cheng, X. & Zhu, Y. yan. Trans. Nonferrous Met. Soc. China (English Ed. 32, 1501 (2022).

Sen S, et al., Anti-sluggish. Scr. Mater. 224 (2023) 115117

I. O. Troyanchuk, S. V. Trukhanov, E. F. Shapovalova, V. A. Khomchenko, M. T. & H. S. J. Exp. Theor. Phys. 96, 1055 (2003).

Oliver W C, and Pharr G M, J. Mater. Res. 19 (2004) 3.

Ding X, Zhan Y, and Tang H, JOM 71 (2019) 3473.

Kao Y L, Tu G C, Huang C A, and Liu T T, Mater. Sci. Eng. A 398 (2005) 93.

Shaikh S M, Hariharan V S, Yadav S K, and Murty B S, Intermetallics 127 (2020) 106926

Kumar N, Biswas K, and Gupta R K, RSC Advances 8 (2016) 111380

Acknowledgements

The authors would like to acknowledge the Department of Science and Technology (DST), Science and Engineering Research Board (SERB), and Indian Institute of Technology Kanpur, India, for supporting us in conducting this study.

Author information

Authors and Affiliations

Contributions

AD performed experimentation, methodology, and data Plotting. SM provides formal analysis and writing—original draft. KB analyzed conceptualization and supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dixit, A., Mahato, S. & Biswas, K. Microstructure Evolution and Mechanical Properties of Dual-Phase Refractory HfTiZr Medium-Entropy Alloy with the Small Addition of Dy and Nd. Trans Indian Inst Met (2023). https://doi.org/10.1007/s12666-023-03195-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12666-023-03195-7