Abstract

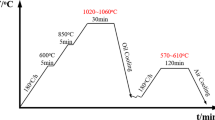

In the present work, the effect of quenching and tempering processes on the sharpness performance of 6Cr13 high-carbon martensitic stainless steel knives was investigated. The results show that the sharp persistence of the knife increases as the quenching temperature increases from 975 to 1125 °C. The initial sharpness first increases and then decreases, reaching a maximum of 95.9 mm at 1075 °C. When the tempering temperature is below 300 °C, the initial sharpness and sharp persistence of the knife both decrease with the increase of tempering temperature. The secondary carbide in the steel dissolved and the carbide content decrease continuously with the increase of quenching temperature. After the quenching temperature exceeds 1050 °C, a large amount of secondary carbide solid solution is formed into the austenite. The carbides precipitate from steel matrix after the tempering temperature exceeds 400 °C. The refinement and dissolution of secondary carbides are the main reasons for the good sharpness performance of 6Cr13 steel knives. The variation of hardness has little effect on the sharpness performance. However, the cutting capacity of knives fluctuates more sharply as the hardness decreases. Quenching at 1050–1075 °C and tempering at 180–220 °C can obtain 6Cr13 steel knives with optimal sharpness, hardness and fine grain size combination.

Similar content being viewed by others

References

McGorry R W, Dowd P C, and Dempsey P G, Appl Ergon 34 (2003) 375. https://doi.org/10.1016/S0003-6870(03)00041-3

Reilly G A, McCormack B A O, and Taylor D, J Mater Process Technol 153 (2004) 261. https://doi.org/10.1016/j.jmatprotec.2004.04.297

Su Z, Huang T, and Fan L, Mater Sci Eng 472 (2019) 012054

Marsot J, Claudon L, and Jacqmin M, Appl Ergon 38 (2007) 83. https://doi.org/10.1016/j.apergo.2005.12.007

Zhu Q, Li J, and Zhang J, J Mater Eng Perform 28 (2019) 4511. https://doi.org/10.1007/s11665-019-04209-6

Wu D, Zhang Q, and Liu W, Metals 12 (2022) 472. https://doi.org/10.3390/met12030472

Roscioli G, Taheri-Mousavi S M, and Tasan C C, Science 369 (2020) 689. https://doi.org/10.1126/science.aba9490

Cobb H M, The History of Stainless Steel, Geauga County, ASM International (2010), p 1.

Lo K H, Shek C H, and Lai J K L, Mater Sci Eng R Rep 65 (2009) 39. https://doi.org/10.1016/j.mser.2009.03.001

Li J, and Shi C, Carbide in Special Steel, Springer, Singapore (2021), pp 1–57.

Chen C Y, Hung F Y, and Lui T S, Metals 6 (2016) 35. https://doi.org/10.3390/met6020035

Zhu Q, Li J, and Shi C, J Mater Eng Perform 24 (2015) 4313. https://doi.org/10.1007/s11665-015-1723-7

Park J Y, and Park Y S, Corrosion (2006). https://doi.org/10.5006/1.3279913

Yuan L L, Han J T, and Liu J, Appl Mech Mater 401 (2013) 916. https://doi.org/10.4028/www.scientific.net/AMM.401-403.916

Siqueira J S, de Abreu Alves M R, and Marcial Luiz T, Mater Corros 72 (2021) 1752. https://doi.org/10.1002/maco.202112483

Ma D, Chi H, and Zhou J, J Iron Steel Res Int 19 (2012) 56. https://doi.org/10.1016/S1006-706X(12)60074-0

Speich G R, and Leslie W C, Metall Trans 3 (1972) 1043. https://doi.org/10.1007/BF02642436

Huang Q, Yao M, and Timokhina I, Metall Mater Trans A 50 (2019) 3663. https://doi.org/10.1007/s11661-019-05272-3

Vitek J M, and Klueh R L, Metall Trans A 14 (1983) 1047. https://doi.org/10.1007/BF02670443

GB/T 8362-1987, Retained Austenite in Steel-Quantitative Determination-Method of X-ray Diffractometer, Bei**g, China (1987).

ISO, ISO 8442-5, Materials and Articles in Contact with Foodstuffs—Cutlery and Table Holloware—Part 5: Specification for Sharpness and Edge Retention Test of Cutlery.

Yang Y, Zhao H, and Dong H, J Mater Eng Perform 29 (2020) 3868.

Zhu Q T, Li J, Zhang J, and Shi C B, J Mater Eng Perform 28 (2019) 4511.

Gilbert R, in International Symposium Held at the 34th Mechanical Working and Steel Processing Conference, Montreal, Quebec, Canada, Iron and Steel Society (1992).

Krishna S C, Gangwar N K, and Jha A K, J Mater Eng Perform 24 (2015) 1656. https://doi.org/10.1007/s11665-015-1431-3

Kashyap B P, and Tangri K, Acta Metall Mater 43 (1995) 3971. https://doi.org/10.1016/0956-7151(95)00110-H

Li X, Ma X, and Subramanian S V, Mater Sci Eng A 616 (2014) 141. https://doi.org/10.1016/j.msea.2014.07.100

Morito S, Saito H, and Ogawa T, ISIJ Int 45 (2005) 91. https://doi.org/10.2355/isi**ternational.45.91

Acknowledgements

This work was supported by the National Nature Science Foundation of China (Grant No. 51874030), the Guangdong Yang Fan Innovative & Entrepreneurial Research Team Program (Grant No. 2016YT03C071) and the Guangdong Science and Technology Special Fund Project (Grant No. SDZX202005).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that no conflicts of interest and ethical rules could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhu, S., Li, J., Li, S. et al. Effect of Quenching and Tempering Processes on Sharpness of Knives Made from 6Cr13 High-Carbon Martensitic Stainless Steel. Trans Indian Inst Met 77, 81–93 (2024). https://doi.org/10.1007/s12666-023-03058-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-023-03058-1