Abstract

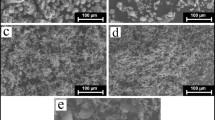

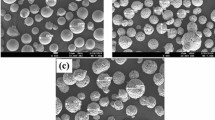

A micro-arc oxidation (MAO) coating was in–situ grew on Ti6Al4V alloy to improve the friction-wear performance, and the morphologies, chemical compositions and phases of obtained coating were analyzed using a scanning electron microscope, energy dispersive spectroscopy, and X–ray diffraction, respectively. The effect of normal load on the tribological performance of MAO coating at 400 °C was investigated on a ball–on–disc wear tester. The results show that the MAO coating exhibits irregular–pore structure, which is mainly composed of TiO2 phase. The coefficient of friction (COF) and wear rate of MAO coating under the normal load of 2 N are 0.32 and of 0.84 × 10–5 mm3 N−1 m−1, respectively, showing the best friction reduction and wear resistance among the three kinds of loads. The wear mechanism of MAO coating under the normal load of 2 N is abrasive wear; while those under the normal loads of 4 and 6 N are adhesion wear fatigue wear, respectively, in which the MAO coating has the tendency of plastic deformation with the increase of normal load.

Similar content being viewed by others

References

Aliofkhazraei M, Macdonald D D, Matykina E, Parfenov E V, Egorkin V S, Curran J A, Troughton S C, Sinebryukhov S L, Gnedenkov S V, Lampke T, Simchen F, and Nabavi H F, Appl Surf Sci Adv 5 (2021) 100121. https://doi.org/https://doi.org/10.1016/j.apsadv.2021.100121.

Zhang L C, Chen L Y, and Wang L Q, Adv Eng Mater 22 (2020) 1901258. https://doi.org/https://doi.org/10.1002/adem.201901258.

Zhang X X, Cai G G, Lv Y, Wu Y L, and Dong Z H, Surf Coat Technol 400 (2020) 126202. https://doi.org/https://doi.org/10.1016/j.surfcoat.2020.126202.

Zhang D Y, Ge Y F, Liu G L, Gao F, and Li P Y, Ceram Int 44 (2018) 16164. https://doi.org/https://doi.org/10.1016/j.ceramint.2018.05.137.

** S Y, Ma X C, Wu R Z, Wang G X, Zhang J H, Krit B, Betsofen S, and Liu B, Appl Surf Sci Adv 8 (2022) 100219. https://doi.org/https://doi.org/10.1016/j.apsadv.2022.100219.

Guo H X, Liu Z Y, Wang Y X, and Li J L, Ceram Int 47 (2021) 7344. https://doi.org/https://doi.org/10.1016/j.ceramint.2020.11.169.

Kücükosman R, Süküroğlu E E, Totik Y, and Süküroğlu S, Surf Interfaces 22 (2021) 100894. https://doi.org/https://doi.org/10.1016/j.surfin.2020.100894.

** K, Wu H, Zhou C L, Qi Z Y, Yang K L, Ricky K Y Fu, **ao S, Wu G, Ding K J, Chen G H, and Paul K Chu, Appl Surf Sci 585 (2022) 152693. https://doi.org/https://doi.org/10.1016/j.apsusc.2022.152693.

** F, Chu P K, Wang K, Zhao J, Huang A, and Tong H, Mater Sci Eng 476 (2008) 7882. https://doi.https://doi.org/10.1016/j.msea.2007.05.070.

Musil J, Kunc F, Zeman H, and Polakova H, Surf Coat Technol 154 (2002) 304313. https://doi.org/https://doi.org/10.1016/S0257-8972(01)01714-5.

Fazel M, HR Salimijazi, Golozar M A, and Garsivaz JMR, Appl Surf Sci 324 (2015) 751756. https://doi.org/https://doi.org/10.1016/j.apsusc.2014.11.030.

Wu B T, Qiu Z J, Dong B S, Wexler D, Pan Z X, Kristin C, Corradi D R, and Li H J, Addit Manuf 54 (2022) 102723. https://doi.org/https://doi.org/10.1016/j.addma.2022.102723.

Chen X W, Li M L, Zhang D F, Cai L P, Ren P, Hu J, and Liao D D, Surf Coat Technol 433 (2022) 128127. https://doi.org/https://doi.org/10.1016/j.surfcoat.2022.128127.

Xu L, Liu N,Cao L, and Wan Y, Int J Appl Ceram Technol 00 (2021) 113. https://doi.org/https://doi.org/10.1111/ijac.13817.

Guo Y F, Xu L Y, Luan J J, Wan Y, and Li R C, Surf Interfaces 28 (2022) 101626. https://doi.org/https://doi.org/10.1016/j.surfin.2021.101626.

Keddam M, and Taktak S, Appl Surf Sci 399 (2017) 229236. https://doi.org/https://doi.org/10.1016/j.apsusc.2016.11.227.

Yang X, Wang W L, Ma W J, Wang Y, Yang J G, Liu S F, and Tang H P, T Nonferr Metal Soc 30 (2020) 2132. https://doi.org/https://doi.org/10.1016/S1003-6326(20)65366-3.

Ozdemir Z, Ozdemir A, and Basim G B, Mater Sci Eng C 68 (2016) 383396. https://doi.org/https://doi.org/10.1016/j.msec.2016.06.002.

Nada Y. Tashkandi, Soha M. Albukhari, and Adel A. Ismail, Opt Mater 127 (2022) 112274. https://doi.org/https://doi.org/10.1016/j.optmat.2022.112274.

Zhou F, Wang Y A, Ding H Y, Wan M L, Yu M, and Dai Z D, Surf Coat Technol 202 (2008) 3808. https://doi.org/https://doi.org/10.1016/j.surfcoat.2008.01.025.

Zhang Z H, Deng J X, Wang R, Sun Q H, Meng Y, and Wu J X, Colloids Surf A Physicochem Eng Asp 647 (2022) 128971. https://doi.org/https://doi.org/10.1016/j.colsurfa.2022.128971.

Nagarjuna C, You H J, Ahn S, Song J W, Jeong K, Madavali B, Song G, Na Y S, Won J W, Kim H S, and Hong S J, Appl Surf Sci 549 (2021) 149202. https://doi.org/https://doi.org/10.1016/j.apsusc.2021.149202.

Ceschini L, Lanzoni E, Martini C, Prandstraller D, and Sambogna G, Wear 264 (2008) 8695. https://doi.org/https://doi.org/10.1016/j.wear.2007.01.045.

Zhao X C, Xu W H, Huang B X, Ma J, Chen H, Hao X H, Ge B, and Wang C Z, Appl Surf Sci 536 (2021) 147968. https://doi.org/https://doi.org/10.1016/j.apsusc.2020.147968.

Guo J, Wang L P, Liang J, Xue Q J, and Yan F Y, J Alloy Compd 481 (2009) 903909. https://doi.org/https://doi.org/10.1016/j.jallcom.2009.03.147.

Dhiflaoui H, Jaber N B, Lazar F S, Faure J, Larbi A B C, and Benhayoune H, Thin Solid Films 638 (2017) 201212. https://doi.org/10.1016/j.tsf.2017.07.056.

Çomaklı O, Yetim T, and Çelik A, Surf Coat Technol 246 (2014) 3439. https://doi.org/10.1016/j.surfcoat.2014.02.059.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non–financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chao, Z., Nan, W. & Dejun, K. Microstructure and Tribological Performance of Micro-Arc Oxidation Coating on Ti6Al4V Alloy. Trans Indian Inst Met 76, 961–967 (2023). https://doi.org/10.1007/s12666-022-02783-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02783-3