Abstract

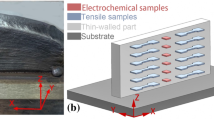

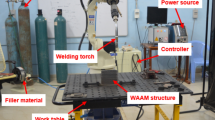

The thin-wall specimens of ER2594 duplex stainless steel (DSS) were prepared by metal electrode inert gas shielded arc welding (MIG). It is found that the duplex stainless steel prepared has good forming quality and almost no defects. Microstructure observation shows that there are ferrite and austenite, and no harmful phases such as sigma—σ—and lambda—λ—are observed due to low heat input and suitable interlaminar temperature. The microhardness distribution of transverse and longitudinal sections is uniform, and the microhardness value has been found to be 285HV0.2 and 301HV0.2, respectively. The mechanical properties of the sample are excellent, transverse yield strength 933 MPa, tensile strength 1013 MPa, elongation 27.7% and 25 ℃ Charpy impact value 229 J; and longitudinal yield strength 860 MPa, tensile strength 941 MPa, elongation 25.2% and 25 ℃ Charpy impact value 228 J. Lastly, the electrochemical test results show that the arc additive manufacturing duplex stainless steel has good corrosion resistance.

Similar content being viewed by others

Date availability

Research date are not shared.

References

Singh S R, Khanna P, Materials Today: Proceedings 44 (2021) 118.

Gao C, Chen X, Su C, Mater Sci Technol 35 (2019) 2234.

Tobias H, Raven T R, and Philipp P B, Additive Manufacturing 41 (2021) 101993.

Zhuo, Y, Yang, C, Fan, C, Lin, S, Chen, C, and Cai, X, Materials Science and Technology 36 (2020) 1712.

Dhinakaran V, Ajith J, and Fahmidha, Materials Today: Proceedings, 21 (2020) 920.

Gyeongbin K, Wooseok K, and Kyungjung K, Metals 11 (2021) 516.

**a C, Pan Z, and Polden J, Journal of Manufacturing Systems 57 (2020) 31.

Qin X, Guangdong W, Haitao Z, Advanced Composites Letters 29 (2020) 263369.

Guo C, Liu M, and Hu R, International Journal of Materials Research 111 (2020) 325.

Rafieazad M, Ghaffari M, Nemani A V, The International Journal of Advanced Manufacturing Technology 105 (2019) 2121.

Lianzhong L, Yinbao T, and Yangchuan C, Materials Letters 298 (2021) 130010.

Shuang L, Qi D Y, and Feng L X, Materials Science Forum 993 (2020) 718.

Yiqi Z, Fangjie C, Shaojie W, Materials Characterization 171 (2021) 110743.

**nya C, Jian H, and Jun W, Materials Letters 300 (2021) 130141.

**guo G, Ningsong F, and Yuhong L, Journal of Alloys and Compounds 860 (2021) 157893.

Dt S, Mj D, Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering 235 (2021) 1439.

Kannan A R, Shanmugam N S, Rajkumar V, and Vishnukumar, M, Materials Letters 270 (2020) 127680.

Dandekar T R, Gupta A, and Khatirkar R K, Transactions of the Indian Institute of Metals 74 (2021) 2267.

Kumar M A, Chandan P, Rahul C, International Journal of Pressure Vessels and Pi** 192 (2021) 104439.

Kannan A R, Shanmugam N S, and Ramkumar K D, Transactions of the Indian Institute of Metals 74 (2021) 1673.

Zhu M, He F, Yuan Y F, Journal of Materials Engineering and Performance 30 (2021) 5652.

Junhe L, Wei S, and ** L, Metals 10 (2020) 1481.

Zhu M, Zhang Q, and Yuan Y, Journal of Electroanalytical Chemistry 864 (2020) 114072.

Zhang X, Wang K, and Zhou Q, Materials&Design 166 (2019) 107611.

ASTM, A 890/A 890M – 99, Standard Specification for Castings, Iron-Chromium-Nickel- Molybdenum Corrosion Resistant, Duplex (Austenitic/Ferritic) for GeneralApplication.

Zhang X, Wang K, and Zhou Q, Materials Science and Engineering:A 762 (2019) 138097.

Acknowledgements

The authors are grateful to the University Synergy Innovation Program of Anhui Province, the Natural Science Foundation of Anhui Province, and the talent program of Anhui Science and Technology Univer for their financial, and the Natural Science Foundation of Colleges and Universities in Anhui Province support through the Grants Numbers GXXT-2019-022, 1908085QE174, and RCYJ201905, KJ2020A0073, respectively.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wu, S., Guo, C., Liu, W. et al. Wire Arc Additive Manufacturing using ER2594 Duplex Stainless Steel. Trans Indian Inst Met 76, 249–258 (2023). https://doi.org/10.1007/s12666-022-02746-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02746-8