Abstract

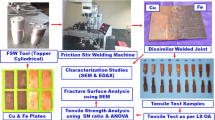

The hybrid interlayers combined with Zn- and Cu-foil are employed in order to strengthen the mechanical properties of Al-5052 friction stir welded joint. During friction stir welding (FSW), the Zn-foil partly melts and dissolves into Al matrix; meanwhile, the Cu-foil gets broken into small detached particles. Compared with the conventional joint, the grains in the nugget zone of interlayer-added joint become finer due to both the decreased FSW temperature and the elevated pinning press. Moreover, the annealing softening and the recrystallization in the heat‐affected zone are inhibited by inserting the hybrid interlayers. Consequently, the hardness and tensile strength of interlayer-added joint are improved in comparison with the conventional joint. In addition, both the stir behavior and the material flow in the nugget zone are enhanced by the application of pin-eccentric stir tool, thus refining and homogenizing the microstructures of nugget zone further.

Similar content being viewed by others

References

Mishra R S, and Ma Z Y, Mater Sci Eng R50 (2005) 1.

Yang C, Ni D R, Xue P, **ao B L, Wang W, Wang K S, and Ma Z Y, Mater Charact145 (2018) 20.

Hao H L, Ni D R, Huang H, Wang D, **ao B L, Nie Z R, and Ma Z Y, Mater Sci Eng A559 (2013) 889.

Sato Y S, Kokawa H, Enomoto M, and Jogan S, Metall Mater Trans A9 (1999) 2429.

Hao H L, Ni D R, Zhang Z, Wang D, **ao B L, and Ma Z Y, Mater Des52 (2013) 706.

Malopheyev S, Vysotskiy I, Kulitskiy V, Mironov S, and Kaibyshev R, Mater Sci Eng A662 (2016) 136.

Zhao Y X, Han J M, Domblesky J P, Yang Z Y, Li Z Q, and Liu X L, J Mater Process Technol37 (2019) 139.

Fu R D, Sun Z Q, Sun R C, Li Y, Liu H J, and Liu L, Mater Des32 (2011) 4825.

Zhang Z, **ao B L, andd Ma Z Y, Mater Sci Eng A614 (2014) 6.

Karthik G M, Ram G D J, and Kottada R S, Mater Sci Eng A684 (2017) 186.

El-Rayes M M, and El-Danaf E A, J Mater Process Technol212 (2012) 1157.

Ji S D, Niu S Y, Liu J G, and Meng X C, J Mater Process Technol267 (2019) 141.

Ji S D, Niu S Y, and Liu J G, J Mater Sci Technol35 (2019) 1712.

Niu S Y, Ji S D, Yan D J, Meng X C, and **ong X H, J Mater Process Technol263 (2019) 82.

Chen Y, Wang H, Wang X Y, Ding H, Zhao J W, Zhang F H, and Ren Z H, Mater Sci Eng A739 (2019) 272.

Zhang J, Huang Y, Liu Y C, and Wang Z M, Mater Des137 (2018) 473.

Chen Y, Wang H, Li H Y, Wang X Y, Ding H, Zhao J W, and Zhang F H, Metals9 (2019) 718.

Azimzadegan T, and Serajzadeh S, J Mater Eng Perform19 (2010) 1256.

Humphreys F J, Acta Mater45 (1997) 5031.

Chen K, Gan W, Okamoto K, Chung K, and Wagoner R H, Metall Mater Trans A42 (2011) 488.

Malopheyev S, Kulitskiy V, Mironov S, Zhemchuzhnikova D, and Kaibyshev R, Mater Sci Eng A600 (2014) 159.

Acknowledgements

The present study is financially supported by the Nature Science Foundation of Liaoning Province (No. 20180550058) and the Fundamental Research Funds for the Central Universities of China (No. N180303029).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, Y., Wang, H., Li, H. et al. Friction Stir Welded Al-5052 Strengthened by the Hybrid Interlayers and Pin-Eccentric Stir Tool. Trans Indian Inst Met 72, 3277–3283 (2019). https://doi.org/10.1007/s12666-019-01796-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-019-01796-9