Abstract

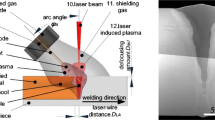

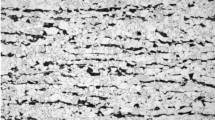

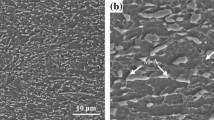

In this work, hybrid laser-arc welding process was applied to X90 pipeline steel which has wide potential applications in the future pipeline project. The effect of different laser power (1.0, 1.5 and 2.5 kW) on microstructure and mechanical properties of weld joints was investigated. It has been found that a macroscopic morphology of “wine cup like” is observed in the weld joint with increasing laser power, where fusion zone (FZ) and heat-affected zone (HAZ) can be clearly identified. The FZ microstructure mainly includes massive ferrite, acicular ferrite (AF), and increased laser power resulting in a decrease in AF content. The HAZ consists of coarse-grained HAZ (CGHAZ), fine-grained HAZ (FGHAZ) and mixed-grained HAZ (MGHAZ). The hardness ranging from the weld center to base metal decreases and then increases, and the effect of laser power on hardness is not significant. The increased laser power leads to an evident decrease in the ultimate tensile strength and impact toughness of weld joint. The highest ultimate tensile strength and impact energy are 815 MPa, 239.1 J respectively at a laser power of 1.0 kW. A number of inclusions are observed at the bottom of dimples, which may be the (Ti,Mn)2O3 particles.

Similar content being viewed by others

References

Liang L, Feng C, Yalong W, **ang Z, and Caihong L, Heat Treat Metals 40 (2015) 190.

Tao N, Yongwen J, Fei L, Guosen Z, **nlang W, and Junkuan W, Chinese J Mater Res 29 (2015) 948.

Jialei Z, Zhifang C, and **angdong J, Electr Weld Mech 44 (2014) 115.

Liu S, Li Y, Liu F, Zhang H, and Ding H, Opt Lasers Eng 81 (2016) 87.

Wang X N, Zhang S H, Zhou J, Zhang M, Chen C J, and Misra R D K, Opt Lasers Eng 91 (2017) 86.

Liu S, Chen S, Wang Q, Li Y, Zhang H, and Ding H, Opt Lasers Eng 92 (2017) 39.

Mirakhorli F, Cao X, Pham X-T, Wanjara P, and Fihey J-L, Metall Mater Trans B 47 (2016) 3245.

Yexiong L, Study on Technologies of Laser-Arc Hybrid Welding for Structural Steel Plates. Dissertation, Jilin University (2013)

Guo B, Fan L, Wang Q, Fu Z, Wang Q, and Zhang F, Metals 6 (2016) 256.

Zhao W, Wang W, Chen S, and Qu J, Mater Sci Eng A 528 (2011) 7417.

Wang X, Li X, Wu S, Shang C, and Wang X, Mater Today Proc 2 (2015) S701.

Dandan G, Microstructure and mechanical properties of laser -MAG hybrid welding on S355J2 W weathering steel. Dissertation, Jilin University (2013)

H Shim J, Oh Y J, Suh J Y, et al, ActaMater 49 (2001) 2115.

Xueli X, **xian X, Kai S, and Yong Z, Trans China Weld Inst 26 (2005) 69.

Chengjia S, Liangjun H, Shanwu Y, Xuemin W, Yuntang Z, **nlai H, Acta Metallurgica Sinica 41 (2005) 471.

Kaiming W, Zigang L, **nlai H, Liqing Z, and Aihua F et al, SIJ Int 46 (2006) 161.

Wang B, Liu X, and Wang G, Metall Mater Trans A 49A (2018) 2124.

Hongyun Z, Jiakun L, Zongan L, Haifeng H, and Guodong W, Trans China Weld Inst 32 (2011) 5.

Zhiqiang S, Yanchang Q, Junli W, and Chenyong M, Mater Mech Eng 40 (2014) 61.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Yang, M., Liu, Y., Zhang, J. et al. Hybrid Laser-Arc Welding of X90 Pipeline Steel: Effect of Laser Power on Microstructure and Mechanical Properties. Trans Indian Inst Met 71, 2487–2496 (2018). https://doi.org/10.1007/s12666-018-1379-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-018-1379-8