Abstract

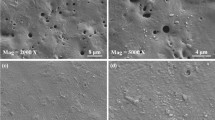

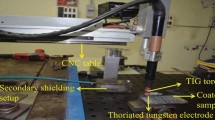

Hard anodized aluminum substrate in sulfuric acid electrolyte was produced and surface hardness and frictional properties of the coated surface were enhanced employing PTFE particles as lubricant. Field emission scanning electron microscope images of anodized layer showed distribution of nano-pores within the surface of high microhardness. Grazing incidence x-ray diffraction patterns revealed the amorphous structure of alumina. Various values of PTFE suspension containing 200–220 nm particles were applied on the hard anodized coating in order to enhance frictional properties. In order to improve PTFE layer adhesion, heat treatment was employed. Pin-on-disc wear tests were performed with AISI 52100 steel pins to study the tribological behavior of the specimens at room and intermediate temperatures. Experimental results indicate that the sample containing 30 ml/l PTFE has the lowest coefficient of friction at ambient temperature; while at 300 °C, a suspension containing 20 ml/l PTFE produces the optimum condition.

Similar content being viewed by others

References

Ebrahimi F, Yazdi S S, Najafabadi M H, and Ashrafizadeh F, Thin Solid Films 592 (2015) 88.

Ebrahimi F, Ashrafizadeh F, Bakhshi S, and Farle M, J. Sol Gel Sci. Technol. 77 (2016) 708.

Malayoglu U, Tekin K C, Malayoglu U, and Shrestha S, Mater. Sci. Eng. A 528 (2011) 7451.

Bhushan B, and Gupta BK, Handbook of Tribology: Materials, Coatings, and Surface Treatments, McGraw-Hill, New York (1991).

Krishna L R, Purnima A S, and Sundararajan G, Wear 261 (2006) 1095.

Wang H W, Skeldon P, and Thompson G E, Surf. Coat. Technol. 88 (1996) 269.

Zhang W, Dong Z, Le Y, Li L, and Ou B, Appl. Surf. Sci. 255 (2008) 2671.

Holmberg K, and Mathews A (eds), Coatings Tribology, 2nd edn. Elsevier, Amsterdam (2009).

Wang H, Yi H, and Wang H, Appl. Surf. Sci. 252 (2005) 1662.

Escobar J, Arurault L, and Turq V, Appl. Surf. Sci. 258 (2015) 8199.

**a Z, Sheldon B W, Curtin W A, Liang J, Yin A, and Xu J M, Adv. Mater. Sci. 6 (2004) 131.

Grosskreutz J C, Electrochem. Soc. 116 (1969) 1232.

Tsangaraki-Kaplanoglou I, Dimogerontakis T H, Wang Y, Kuo H, and Kia S, Surf. Coat. Technol. 200 (2006) 2634.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shirmohammadi Yazdi, S., Ebrahimi, F. & Ashrafizadeh, F. Enhancement of High Temperature Frictional Properties of Nanostructured Hard Anodized Coatings by PTFE Solid Lubricant. Trans Indian Inst Met 71, 1507–1518 (2018). https://doi.org/10.1007/s12666-018-1286-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-018-1286-z