Abstract

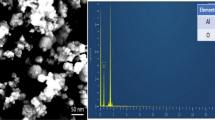

In the current research, the influence of multi-pass of friction stir welding and SiC microparticles on the tensile strength, microhardness, and %strain of dissimilar reinforced joints of AA6082 and AA5083 was examined. A tool rotating speed of 900 rpm, a transverse speed of 45 mm/min, a tool tilt angle of 2º and 8% volume percentage of SiC microparticles were considered as parameters for multi-pass FSW. The finding demonstrated that increasing the number of FSW passes from one to three augmented the dispersion pattern of SiC microparticles. The grain refinement of multi-pass reinforced joints was achieved by the pinning effect of SiC microparticles and dynamic recrystallization. The three-passes FSWed reinforced joint exhibited the highest tensile strength (247.17 MPa), % strain (13.1%), and microhardness (126.6 HV) due to the higher grain refinement.

Similar content being viewed by others

Data Availability

All the data and information mentioned in this article are related to this research.

References

Rahmatian B, Dehghani K (2020) Seyyed Ehsan Mirsalehi, Effect of adding SiC nanoparticles to nugget zone of thick AA5083 aluminium alloy joined by using double-sided friction stir welding. J Manuf Process 52:152–164

Singh T, Tiwari SK, Shukla DK (2020) effects of Al2O3 nanoparticles volume fractions on microstructural and mechanical characteristics of friction stir welded nanocomposites. Nanocomposites 6(2):76–84

Uday KN, Rajamurugan G (2023) Influence of process parameters and its effects on friction stir welding of dissimilar aluminium alloy and its composites – a review. J Adhes Sci Technol 37(5):767–800

Suresh S, Natarajan Elango, Shanmugam Ragavanantham et al (2022) Strategized friction stir welded AA6061-T6/SiC composite lap joint suitable for sheet metal applications. J Mater Res Technol 21:30–39

Orłowska M, Pixner F, Hütter A et al (2022) Manufacturing of coarse and ultrafine-grained aluminum matrix composites reinforced with Al2O3 nanoparticles via friction stir processing. J Manuf Process 80:359–373

Barmouz M, Asadi P, Besharati Givi MK et al (2011) Investigation of mechanical properties of Cu/SiC composite fabricated by FSP: effect of SiCparticles’ size and volume fraction. Mater Sci Eng A 528(3):1740–1749

Tonelli L, Morri A, Toschi S et al (2019) Effect of FSP parameters and tool geometry on microstructure, hardness, and wear properties of AA7075 with and without reinforcing B C ceramic particles. Int J Adv Manuf Technol 102(9–12):3945–3917

Deore HA, Mishra J, Rao AG et al (2019) Effect of filler material and post-process ageing treatment on microstructure, mechanical properties and wear behaviour of friction stir processed AA 7075 surface composites. Surf Coat Technol 374:52–64

Khodabakhshi F, Nosko M, Gerlich AP (2018) Effect of graphene nano-platelets (GNPs)on the microstructural characteristics and textural development of an Al-Mg alloy during friction-stir processing. Surf Coat Technol 335:288–305

Ahmad Fauzi MN, Uday MB, Zuhailawati H, Ismail AB (2010) Microstructure and mechanical properties of alumina-6061aluminum alloy joined by friction welding. Mater Des 31:670–6

Kuryntsev S (2022) a Review: Laser Welding of Dissimilar Materials (Al/Fe, Al/Ti, Al/Cu)—Methods and Techniques, Microstructure and Properties. Materials 15(1):122. https://doi.org/10.3390/ma15010122

Bohm M, Kowalski M (2020) Fatigue life estimation of explosive cladded transition joints with the use of the spectral method for the case of a random sea state. Marine Structures 71:102739. https://doi.org/10.1016/j.marstruc.2020.102739

Uzun H (2007) Friction stir welding of SiC particulate reinforced AA2124 aluminium alloy matrix composite. Mater Des 28(5):1440–1446

Ceschini L, Boromei I, Minak G et al (2007) Effect of friction stir welding on microstructure, tensile and fatigue properties of the AA7005/10 vol.%Al2O3 composite. Compos Sci Technol. 67(3–4):605–615

Feng AH, **ao BL, Ma ZY (2008) Effect of microstructural evolution on mechanical properties of friction stir welded AA2009/SiC composite. Compos Sci Technol 68(9):2141–2148

Kumar KS, Murigendrappa SM, Kumar H (2019) Experimental investigation on effects of varying volume fractions of SiC nanoparticle reinforcement on microstructure and mechanical properties in friction stir welded dissimilar joints of AA2024-T351 and AA7075-T651. J Mater Res 34, 1229–1247

Ashok Kumar R, Ragav GR, Nagarajan KJ et al (2019) Effect of hybrid reinforcement at stirred zone of dissimilar aluminum alloys during friction stir welding. Metall Res Technol 116:631

Mirihanage W, Munasinghe N (2004) Modification of AA 5083 weld joint characteristics, International Symposium of Research Students on Materials Science and Engineering, Chennai, India, ISRS, pp. 1–6

Peasura P, Watanapa A (2012) Influence of shielding gas on aluminum alloy 5083 in gas tungsten arc welding. Procedia Eng 29:2465–2469

Cetinel H, Manisa MA. Microstructure and Mechanical Properties of AA 5083 and AA 6061 Welds Joined with AlSi5 and AlSi12 Wires*, 3rd International Conference on Welding Technologies and Exhibition (ICWET’14) in Manisa, Turkey

Erdoğan AA, Feyzullahoğlu E, Fidan S, Sinmazçelik T (2020) Investigation of erosive wear behaviors of AA6082-T6 aluminum alloy. Proc Inst Mech Eng L J Mater Des Appl 234(3):520–530

Rathee S, Maheshwari S, Siddiquee AN et al (2017) Effect of tool plunge depth on reinforcement particles distribution in surface composite fabrication via friction stir processing. Def Technol 13(2):86–91

Rathee S, Maheshwari S, Siddiquee AN et al (2017) Analysis of microstructural changes in enhancement of surface properties in sheet forming of Al alloys via friction stir processing. Mater Today Proc 4(2):452–458

Tipu G, RK, Goyal A (2020) Experimental Investigations on FSW of AA6082-T6 Aluminum Alloy, Advances in Materials Processing, Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-15-4748-5_1

Ilangovan M, Rajendra Boopathy S, Balasubramanian V (2015) Effect of tool pin profile on microstructure and tensile properties of friction stir welded dissimilar AA 6061–AA 5086 aluminium alloy joints. Defence Technol 11(2):174–184

Donatus U, Thompson GE, Zhou X, Wang J, Beamish K (2015) Flow patterns in friction stir welds of AA5083 and AA6082 alloys. Mater Des 83(2015):203–213

Msomi V, Moni V (2021) The influence of materials positioning on microstructure and mechanical properties of friction stir welded AA5083/AA6082 dissimilar joint. Adv Mater Process Technol 8(2):2087–2101

Mehdi H, Mehmood A, Chinchkar A, Hashmi AW, Malla C, Mohapatra P (2022) Optimization of process parameters on the mechanical properties of AA6061/Al2O3 nanocomposites fabricated by multi-pass friction stir processing. Mater Today Proc 56(4):1995–2003

Mehdi Husain, Mishra RS (2020) An experimental analysis and optimization of process parameters of AA6061 and AA7075 welded joint by TIG+FSP welding using RSM. Adv Mater Process Technol 8(1):598–620

Srinivasu R, Rao AS, Reddy GM, Rao KS (2015) Friction stir surfacing of cast A356 aluminum silicon alloy with boron carbide and molybdenum disulphide powders. Defence Technol 11:140–146

Jain S, Mishra RS (2021) Effect of Al2O3 nanoparticles on microstructure and mechanical properties of friction stir-welded dissimilar aluminum alloys AA7075-T6 and AA6061-T6, 2021. Proc Inst Mech Eng E J Process Mech Eng 236(4):1511–1521

Hasan MJ, Ramezani H, Ghobadi H, Mohammad A, Yari S, Besharati Givi MK (2016) Processing–structure–property correlation in Nano-SiC-reinforced friction stir welded aluminum joints. J Manuf Process 21:180–189

Asadi P, Faraji G, Besharati Givi MK (2010) Producing of AZ91/SiC composite by Friction stir processing (FSP). Int J Adv Manuf Technol 51:247–260

Mehdi H, Mishra RS (2020) Influence of Friction Stir Processing on Weld Temperature Distribution and Mechanical Properties of TIG-Welded Joint of AA6061 and AA7075. Trans Indian Inst Metals 73:1773–1788. https://doi.org/10.1007/s12666-020-01994-w

Srivastava M, Rathee S, Siddiquee AN et al (2019) Investigation on the Effects of Silicon Carbide and Cooling Medium during Multi-Pass FSP of Al-Mg/ SiC Surface Composites. Silicon 11:2149–2157

Humphreys FJ, Hatherly M (2004) Chapter 11 - grain growth following recrystallization, in: Recrystallization and Related Annealing Phenomena.Elsevier Ltd., 333–378. https://doi.org/10.1016/B978-008044164-1/50015-3

Sun YF, Fujii H (2011) The effect of SiC particles on the microstructure and mechanical properties of friction stir welded pure copper joints. Mater Sci Eng A 528:5470–5475

Chen XG, Da Silva M, Gougeon P, St-Georges L (2009) Microstructure and mechanical properties of friction stir welded AA6063–B4C metal matrix composites. Mater Sci Eng A 518(1–2):174–184

Kumar KSA, Murigendrappa SM, Kumar H (2019) Experimental investigation on effects of varying volume fractions of SiC nanoparticle reinforcement on microstructure and mechanical properties in friction-stir-welded dissimilar joints of AA2024-T351 and AA7075-T651. J Mater Res 34(7):1229–1247

Srivatsan T, Narendra N, Troxell J (2000) Tensile deformation and fracture behavior of an oxide dispersion strengthened copper alloy. Mater Des 21:191–198

Salah AN, Mabuwa S, Mehdi H, Msomi V, Kaddami M, Mohapatra P (2022) Effect of Multipass FSP on Si-rich TIG Welded Joint of Dissimilar Aluminum Alloys AA8011-H14 and AA5083-H321: EBSD and Microstructural Evolutions. Silicon. https://doi.org/10.1007/s12633-022-01717-4

Sharma DK, Patel V, Badheka V et al (2019) Fabrication of hybrid surface composites AA6061/(B 4 C+MoS) via friction stir processing. J Tribology 141:52201–52210

Paidar M (2016) Sarab ML Friction stir spot welding of 2024–T3 aluminum alloy with SiC nanoparticles. J Mech Sci Technol 30:365–370. https://doi.org/10.1007/s12206-015-1241-4

Paidar M, Asgari A, Ojo OO et al (2018) Mechanical Properties and Wear Behavior of AA5182/WC Nanocomposite Fabricated by Friction Stir Welding at Different Tool Traverse Speeds. J Mater Eng Perform 27:1714–1724

Li C, Feng X, Shen Y, Chen W (2016) Preparation of Al2O3/TiO2 particle-reinforced copper through plasma spraying and friction stir processing. Mater Des 90:922–930

Shafiei-Zarghani A, Kashani-Bozorg SF, Zarei-Hanzaki A (2009) Microstructures and mechanical properties of Al/Al2O3 surface nano-composite layer produced by friction stir processing. Mater Sci Eng A 500(1):84–91

Su JQ, Nelson TW, Mishra R, Mahoney M (2003) Microstructural Investigation Friction Stir Welded 7050–T651 Aluminium. Acta Mater 51:713–729

Barmouz M, Givi MKB (2011) Fabrication of in situ Cu/SiC composites using multi-pass friction stir processing: Evaluation of microstructural, porosity, mechanical and electrical behavior. Compos A Appl Sci Manuf 42(10):1445–1453

Lloyd DJ (1994) Particle reinforced aluminum and magnesium matrix composites. Int Mater Rev 39:1

Yadav D, Bauri R (2011) Processing, microstructure and mechanical properties of nickel particles embedded aluminium matrix composite. Mater Sci Eng A 528:1326–1333

Rani P, Mishra R (2022) Influence of Reinforcement with Multi-Pass FSW on the Mechanical and Microstructural Behavior of Dissimilar Weld Joint of AA5083 and AA6061. Silicon 14:11219–11233. https://doi.org/10.1007/s12633-022-01863-9

Paidar M, Bokov M (2021) Mehrez S et al Improvement of mechanical and wear behavior by the development of a new tool for the friction stir processing of Mg/B4C composite. Surf Coat Technol 426:127797

Chang CI, Lee CJ, Huang JC (2004) Relationship between grain size and Zener-Holloman parameter during friction stir processing in AZ31 Mg alloys. Scripta Mater 51:509–514

Jamalian HM, Ramezani H, Ghobadi H, Ansari M, Yari S, Givi MKB (2016) Processing–structure–property correlation in nano-SiC-reinforced friction stir welded aluminum joints. J Manuf Process 21:180–189

Azizieh M, Kokabi AH, Abachi P (2011) Effect of rotational speed and probe profile on microstructure and hardness of AZ31/Al2O3 nanocomposites fabricated by friction stir processing. Mater Des 32(4):2034–2041

Salehi M, Saadatmand M, Aghazadeh Mohandesi J (2012) Optimization of process parameters for producing AA6061/SiC nanocomposites by friction stir processing. Trans Nonfer Metals Soc China 22(5):1055–1063

Pandey C, Saini N, Mahapatra MM, Kumar P (2017) Study of the fracture surface morphology of impact and tensile tested cast and forged (C&F) Grade 91 steel at room temperature for different heat treatment regimes. Eng Fail Analy 71:131–147

El-RayesMM, El-Danaf EA (2012) The influence of multi-pass friction stir processing on the microstructural and mechanical properties of Aluminum Alloy 6082. J Mater Process Technol 212 (5):1157–1168. https://doi.org/10.1016/J.JMATPROTEC.2011.12.017

McNelley TR, Swaminathan S, Su JQ (2008) Recrystallization mechanisms during friction stir welding/processing of aluminum alloys. Scr Mater 58:349–354

Genevois C, Deschamps A, Denquin A, Doisneau-cottignies B (2005) Quantitative investigation of precipitation and mechanical behaviour for AA2024 friction stir welds. Acta Mater 53(8):2447–2458

Chen YC, Feng JC, Liu HJ (2009) Precipitate evolution in friction stir welding of 2219–T6 aluminum alloys. Mater Charact 60(6):476–481

Acknowledgements

The authors would like to express gratitude to Department at the Mechanical Engineering in DTU, Delhi.

Author information

Authors and Affiliations

Contributions

Sumit Jain and R.S. Mishra: Writing and reviewing of article.

Husain Mehdi: Drafting and reviewing.

Corresponding author

Ethics declarations

Compliance with Ethical Standards

Yes.

Consent to Participate

No objection.

Consent for Publication

No objection.

Informed consent

Not applicable.

Conflict-of-Interest

No.

Competing Interests

No competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jain, S., Mishra, R.S. & Mehdi, H. Influence of SiC Microparticles and Multi-Pass FSW on Weld Quality of the AA6082 and AA5083 Dissimilar Joints. Silicon 15, 6185–6197 (2023). https://doi.org/10.1007/s12633-023-02455-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-023-02455-x