Abstract

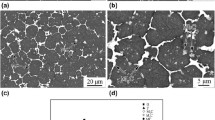

This work investigated the effect of Cr and Si on the mechanical properties and oxidation resistance of press hardened steel. Results indicated that the microstructure of the Cr–Si micro-alloyed press hardened steel consisted of lath martensite, M23C6 carbides, and retained austenite. The retained austenite and carbides are responsible for the increase in elongation of the micro-alloyed steel. In addition, after oxidation at 930°C for 5 min, the thickness of the oxide scales on the Cr–Si micro-alloyed press hardened steel is less than 5 µm, much thinner than 45.50 µm-thick oxide scales on 22MnB5. The oxide scales of the Cr–Si micro-alloyed steel are composed of Fe2O3, Fe3O4, mixed spinel oxide (FeCr2O4 and Fe2SiO4), and amorphous SiO2. Adding Cr and Si significantly reduces the thickness of the oxide scales and prevents the generation of the FeO phase. Due to the increase of spinel FeCr2O4 and Fe2SiO4 phase in the inner oxide scale and the amorphous SiO2 close to the substrate, the oxidation resistance of the Cr–Si micro-alloyed press hardened steel is improved.

Similar content being viewed by others

References

K. Mori, P.F. Bariani, B.A. Behrens, et al., Hot stam** of ultra-high strength steel parts, CIRP Ann., 66(2017), No. 2, p. 755.

J.T. Liang, H.Z. Lu, L.L. Zhang, et al., A 2000 MPa grade Nb bearing hot stam** steel with ultra-high yield strength, Mater. Sci. Eng. A, 801(2021), art. No. 140419.

Y.G. Yang, Z.L. Mi, H.T. Jiang, et al., Effects of the austenitizing temperature on the microstructure and mechanical properties in multiple-phase medium Mn steel, Mater. Res. Express, 6(2020), No. 12, art. No. 1265c9.

S.S. Li and H.W. Luo, Medium-Mn steels for hot forming application in the automotive industry, Int. J. Miner. Metall. Mater., 28(2021), No. 5, p. 741.

J. Hu, J.M. Zhang, G.S. Sun, et al., High strength and ductility combination in nano-/ultrafine-grained medium-Mn steel by tuning the stability of reverted austenite involving intercritical annealing, J. Mater. Sci., 54(2019), No. 8, p. 6565.

J. Hu, L.X. Du, W. Xu, et al., Ensuring combination of strength, ductility and toughness in medium-manganese steel through optimization of nano-scale metastable austenite, Mater. Charact., 136(2018), p. 20.

Y. Chang, X.D. Li, K.M. Zhao, et al., Influence of stress on martensitic transformation and mechanical properties of hot stamped AHSS parts, Mater. Sci. Eng. A, 629(2015), p. 1.

H.L. Yi, Z.Y. Chang, H.L. Cai, P.J. Du, and P.D. Yang, Strength, ductility and fracture strain of press-hardening steels, Acta Metall. Sin., 56(2020), No. 4, p. 429.

L. Lin and J.Q. Zeng, Consideration of green intelligent steel processes and narrow window stability control technology on steel quality, Int. J. Miner. Metall. Mater., 28(2021), No. 8, p. 1264.

X.L. Yu, Z.Y. Jiang, J.W. Zhao, et al., Local strain analysis of the tertiary oxide scale formed on a hot-rolled steel strip via EBSD, Surf. Coat. Technol., 277(2015), p. 151.

J. Wang, W. Yu, E.T. Dong, and J.X. Shi, Evolution of oxide structures of low-alloy steel surface during short-time oxidation at high temperature, [in] Advances in Materials Processing: Proceedings of Chinese Materials Conference 2017 18th, Yinchuan, 2018, p. 725.

C. Wang, H.B. Wu, Z.C. Li, P.C. Zhang, and L.L. Li, Microtexture and rolling deformation behavior analysis of the formation mechanism Fe3O4 at the interface formed on hot-rolled high-strength steel, Metals, 11(2021), No. 2, art. No. 312.

Y.B. Zhang, D.N. Zou, X.Q. Wang, Q.S. Wang, R. Xu, and W. Zhang, Influences of Si content on the high-temperature oxidation behavior of X10CrAlSi18 ferritic heat-resistant stainless steel at 700°C and 800°C, Surf. Coat. Technol., 422(2021), art. No. 127523.

M.H. Su, J.H. Zhao, Z.H. Tian, and C. Gu, Short-term oxidation behavior of 304 stainless steel in N2–21vol%O2 environment between 900 and 1200°C, Corros. Sci., 208(2022), art. No. 110612.

S.R. Kim, S. Lee, H.G. Kang, and J.W. Park, Oxide scale on stainless steels and its effect on sticking during hot-rolling, Corros. Sci., 164(2020), art. No. 108357.

Z. Shen, K. Chen, H.B. Yu, et al., New insights into the oxidation mechanisms of a ferritic–martensitic steel in high-temperature steam, Acta Mater., 194(2020), p. 522.

M. Windmann, A. Röttger, and W. Theisen, Phase formation at the interface between a boron alloyed steel substrate and an Alrich coating, Surf. Coat. Technol., 226(2013), p. 130.

T. Taylor and A. Clough, Critical review of automotive hot-stamped sheet steel from an industrial perspective, Mater. Sci. Technol., 34(2018), No. 7, p. 809.

Z.B. Dai, H. Chen, R. Ding, et al., Fundamentals and application of solid-state phase transformations for advanced high strength steels containing metastable retained austenite, Mater. Sci. Eng. R Rep., 143(2021), art. No. 100590.

D. Bhattacharya, L. Cho, D. Marshall, et al., Liquid metal embrittlement susceptibility of two Zn-coated advanced high strength steels of similar strengths, Mater. Sci. Eng. A, 823(2021), art. No. 141569.

Z.R. Hou, J.Y. Min, J.F. Wang, et al., Effect of rapid heating on microstructure and tensile properties of a novel coating-free oxidation-resistant press-hardening steel, JOM, 73(2021), No. 11, p. 3195.

Z.R. Hou, J.F. Wang, Q. Lu, et al., Short process hot forming technology and microstructure evolution of ultra-high strength steels, J. Mech. Eng., 58(2022), No. 16, p. 43.

Y. Zhao, D.C. Yang, Z. Qin, X.H. Chu, J.H. Liu, and Z.Z. Zhao, A novel hot stam** steel with superior mechanical properties and antioxidant properties, J. Mater. Res. Technol., 21(2022), p. 1944.

W. Carl, Formation of composite scales consisting of oxides of different metals, J. Electrochem. Soc., 103(1956), No. 11, art. No. 627.

T. Fukagawa, H. Okada, and Y. Maehara, Mechanism of red scale defect formation in Si-added hot-rolled steel sheets, ISIJ Int., 34(1994), No. 11, p. 906.

A. Col, V. Parry, and C. Pascal, Oxidation of a Fe–18Cr–8Ni austenitic stainless steel at 850°C in O2: Microstructure evolution during breakaway oxidation, Corros. Sci., 114(2017), p. 17.

D. Singh, F. Cemin, M.J.M. Jimenez, et al., High-temperature oxidation behaviour of nanostructure surface layered austenitic stainless steel, Appl. Surf. Sci., 581(2022), art. No. 152437.

R. Zhu, M. Wang, Z.L. Mi, et al., Effects of nano-ceramic additives on high-temperature mechanical properties and corrosion behavior of 310S austenitic stainless steel, J. Iron Steel Res. Int., 30(2023), No. 3, p. 591.

Q. Yuan, G. Xu, M.X. Zhou, and B. He, The effect of the Si content on the morphology and amount of Fe2SiO4 in low carbon steels, Metals, 6(2016), No. 4, art. No. 94.

S. Wang, Y. Wu, F. Gesmundo, and Y. Niu, The effect of Si additions on the high-temperature oxidation of a ternary Ni–10Cr–4Al alloy in 1 atm O2 at 900–1000°C, Oxid. Met., 69(2008), No. 5, p. 299.

Z.S. Chai, L.Y. Wang, Z. Wang, et al., Cr-enriched carbide induced stabilization of austenite to improve the ductility of a 1.7 GPa–press-hardened steel, Scr. Mater., 224(2023), art. No. 115108.

J. Hu, L.X. Du, Y. Dong, Q.W. Meng, and R.D.K. Misra, Effect of Ti variation on microstructure evolution and mechanical properties of low carbon medium Mn heavy plate steel, Mater. Charact., 152(2019), p. 21.

Y. Liu, Y.H. Sun, and H.T. Wu, Effects of chromium on the microstructure and hot ductility of Nb-microalloyed steel, Int. J. Miner. Metall. Mater., 28(2021), No. 6, p. 1011.

H.W. Luo, X.H. Wang, Z.B. Liu, and Z.Y. Yang, Influence of refined hierarchical martensitic microstructures on yield strength and impact toughness of ultra-high strength stainless steel, J. Mater. Sci. Technol., 51(2020), p. 130.

Z.R. Hou, T. Opitz, X.C. **ong, X.M. Zhao, and H.L. Yi, Bake-partitioning in a press-hardening steel, Scr. Mater., 162(2019), p. 492.

H.P. Liu, X.W. Lu, X.J. **, H. Dong, and J. Shi, Enhanced mechanical properties of a hot stamped advanced high-strength steel treated by quenching and partitioning process, Scr. Mater., 64(2011), No. 8, p. 749.

L. Liu, B.B. He, and M.X. Huang, The role of transformation-induced plasticity in the development of advanced high strength steels, Adv. Eng. Mater., 20(2018), No. 6, art. No. 1701083.

J. Hu, X.Y. Li, Q.W. Meng, L.Y. Wang, Y.Z. Li, and W. Xu, Tailoring retained austenite and mechanical property improvement in Al–Si–V containing medium Mn steel via direct intercritical rolling, Mater. Sci. Eng. A, 855(2022), art. No. 143904.

X.J. **, S.H. Chen, and L.J. Rong, Effects of Mn on the mechanical properties and high temperature oxidation of 9Cr2WVTa steel, J. Nucl. Mater., 494(2017), p. 103.

S.C. Zhang, H.B. Li, Z.H. Jiang, et al., Unveiling the mechanism of yttrium significantly improving high-temperature oxidation resistance of super-austenitic stainless steel S32654, J. Mater. Sci. Technol, 115(2022), p. 103.

H.L. Zhao, L.F. Li, and Q. Feng, Isothermal oxidation behavior of Nb-bearing austenitic cast steels at 950°C, Int. J. Miner. Metall. Mater., 29(2022), No. 4, p. 814.

J. Wang, S.P. Lu, L.J. Rong, D.Z. Li, and Y.Y. Li, Effect of silicon on the oxidation resistance of 9 wt.% Cr heat resistance steels in 550°C lead-bismuth eutectic, Corros. Sci., 111(2016), p. 13.

Z.Y. Xu, L.L. Song, Y.Y. Zhao, and S.J. Liu, The formation mechanism and effect of amorphous SiO2 on the corrosion behaviour of Fe–Cr–Si ODS alloy in LBE at 550°C, Corros. Sci., 190(2021), art. No. 109634.

L.L. Zhang, W. Yan, Q.Q. Shi, Y.F. Li, Y.Y. Shan, and K. Yang, Silicon enhances high temperature oxidation resistance of SIMP steel at 700°C, Corros. Sci., 167(2020), art. No. 108519.

J. Issartel, S. Martoia, F. Charlot, et al., High temperature behavior of the metal/oxide interface of ferritic stainless steels, Corros. Sci., 59(2012), p. 148.

G.H. Meier, K. Jung, N. Mu, et al., Effect of alloy composition and exposure conditions on the selective oxidation behavior of ferritic Fe–Cr and Fe–Cr–X alloys, Oxid. Met., 74(2010), No. 5, p. 319.

A. Atkinson and J.W. Gardner, The diffusion of Fe3+ in amorphous SiO2 and the protective properties of SiO2 layers, Corros. Sci., 21(1981), No. 1, p. 49.

A.C.S. Sabioni, A.M. Huntz, F. Silva, and F. Jomard, Diffusion of iron in Cr2O3: Polycrystals and thin films, Mater. Sci. Eng. A, 392(2005), No. 1–2, p. 254.

B. Li and B. Gleeson, Effects of silicon on the oxidation behavior of Ni-base chromia-forming alloys, Oxid. Met., 65(2006), No. 1, p. 101.

L. Shen, Y.N. Wang, T.F. **g, H.B. Peng, and Y.H. Wen, Oxidation resistance and mechanical properties of Al2O3-forming and SiO2-forming austenitic stainless steels between 1023 K and 1173 K, Corros. Sci., 211(2023), art. No. 110914.

R. Bauer, M. Baccalaro, L.P.H. Jeurgens, M. Pohl, and E.J. Mittemeijer, Oxidation behavior of Fe–25Cr–20Ni–2.8Si during isothermal oxidation at 1286K; life-time prediction, Oxid. Met., 69(2008), No. 3, p. 265.

W.B. Du, C.J. Liu, and Y.Y. Yue, Effect of passivation on the high-temperature oxidation behavior of hot-formed steel, Corros. Sci., 202(2022), art. No. 110318.

S. Zhang, Y.L. Zhang, and S.W Wu, Effects of ZnO, FeO and Fe2O3 on the spinel formation, microstructure and physico-chemical properties of augite-based glass ceramics, Int. J. Miner. Metall. Mater., 30(2023), No. 6, p. 1207.

Z.X. Shi, S.Z. Liu, M. Han, and J.R. Li, Influence of yttrium addition on high temperature oxidation resistance of single crystal superalloy, J. Rare Earths, 31(2013), No. 8, p. 795.

Y.F. Zhang, D.M. Zhu, and D.A. Shores, Effect of yttrium on the oxidation behavior of cast Ni–30Cr alloy, Acta Metall. Mater., 43(1995), No. 11, p. 4015.

Acknowledgements

The authors gratefully acknowledge the financial support from the National Natural Science Foundation of China (Nos. 52274372 and 52201101), the National Key R&D Program of China (No. 2021YFB3702404), and the Fundamental Research Funds for the Central Universities (No. FRF-TP-22-013A1).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

All authors confirm that they have no competing interests or financial ties that could influence the outcomes or interpretation of this research.

Rights and permissions

About this article

Cite this article

Zhu, R., Yang, Y., Zhang, B. et al. Improving mechanical properties and high-temperature oxidation of press hardened steel by adding Cr and Si. Int J Miner Metall Mater (2024). https://doi.org/10.1007/s12613-023-2796-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12613-023-2796-1