Abstract

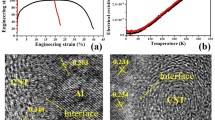

Ti3AlC2-reinforced Ag-based composites, which are used as sliding current collectors, electrical contacts, and electrode materials, exhibit remarkable performances. However, the interfacial reactions between Ag and Ti3AlC2 significantly degrade the electrical and thermal properties of these composites. To diminish these interfacial reactions, we fabricated carbon-coated Ti3AlC2 particles (C@Ti3AlC2) as reinforcement and prepared Ag-10wt%C@Ti3AlC2 composites with carbon-layer thicknesses ranging from 50–200 nm. Compared with the uncoated Ag-Ti3AlC2 composite, Ag-C@Ti3AlC2 was found to have a better distribution of Ti3AlC2 particles. With increases in the carbon-layer thickness, the Vickers hardness value and relative density of Ag-C@Ti3AlC2 gradually decreases. With a carbon-layer thickness of 150 nm, we obtained the lowest resistivity of Ag-C@Ti3AlC2 of 29.4 135.5×10-9 Ω·m, which is half that of Ag-Ti3AlC2 (66.7 × 10-9 Ω·m). The thermal conductivity of Ag-C@Ti3AlC2 reached a maximum value of 135.5 W·m-1·K-1 with a 200-nm carbon coating (~1.8 times that of Ag-Ti3AlC2). These results indicate that the carbon-coating method is a feasible strategy for improving the performance of Ag-C@Ti3AlC2 composites.

Similar content being viewed by others

References

M.W. Barsoum, The Mn+1AXn phases: A new class of solids: Thermodynamically stable nanolaminates, Prog. Solid State Chem., 28(2000, No. 1-4, p. 201.

Z.M. Sun, Progress in research and development on MAX phases: A family of layered ternary compounds, Int. Mater. Rev., 56(2011, No. 3, p. 143.

N.V. Tzenov and M.W. Barsoum, Synthesis and characterization of Ti3AlC2, J. Am. Ceram. Soc., 83(2000, No. 4, p. 825.

M.W. Barsoum, H.I. Yoo, I.K. Polushina, V.Y. Rud’, Y.V. Rud’, and T. El-Raghy, Electrical conductivity, thermopower, and Hall effect of Ti3AlC2, Ti4AlN3, and Ti3SiC2, Phys. Rev. B, 62(2000), No. 15, p. 10194.

P.C. Wingert and C.H. Leung, The development of silver-based cadmium-free contact materials, IEEE Trans. Compon. Hybrids Manuf. Technol., 12(1989, No. 1, p. 16.

M.M. Liu, J.L. Chen, H. Cui, S.H. Liu, X.D. Sun, M. **e, and X.D. Li, Temperature-driven deintercalation and structure evolution of Ag/Ti3AlC2 composites, Ceram. Int., 44(2018, No. 15, p. 18129.

T. El-Raghy, M.W. Barsoum, and M. Sika, Reaction of Al with Ti3SiC2 in the 800-1000°C temperature range, Mater. Sci. Eng. A, 298(2001, No. 1-2, p. 174.

C.L. Zhou, X.Y. Wu, T.L. Ngai, L.J. Li, S. Ngai, and Z.M. Chen, Al alloy/Ti3SiC2 composites fabricated by pressureless infiltration with melt-spun Al alloy ribbons, Ceram. Int., 44(2018, No. 6, p. 6026.

Y. Zhang, Z.M. Sun, and Y.C. Zhou, Cu/Ti3SiC2 composite: A new electrofriction material, Mater. Res. Innovations, 3(1999, No. 2, p. 80.

J. Zhang, J.Y. Wang, and Y.C. Zhou, Structure stability of Ti3AlC2 in Cu and microstructure evolution of Cu-Ti3AlC2 composites, Acta Mater., 55(2007, No. 13, p. 4381.

J.X. Ding, W.B. Tian, D.D. Wang, P.G. Zhang, J. Chen, Y.M. Zhang, and Z.M. Sun, Microstructure evolution, oxidation behavior and corrosion mechanism of Ag/Ti2SnC composite during dynamic electric arc discharging, J. Alloys Compd., 785(2019), p. 1086.

T. Okamoto, Interfacial structure of metal-ceramic joints, ISIJ Int., 30(1990, No. 12, p. 1033.

O.M. Akselsen, Diffusion bonding of ceramics, J. Mater. Sci., 27(1992, No. 3, p. 569.

N. Eustathopoulos, Dynamics of wetting in reactive metal/ceramic systems, Acta Mater., 46(1998, No. 7, p. 2319.

J.R. Lu, Y. Zhou, Y. Zheng, H.Y. Li, and S.B. Li, Interface structure and wetting behaviour of Cu/Ti3SiC2 system, Adv. Appl. Ceram., 114(2015, No. 1, p. 39.

T.L. Ngai, W. Zheng, and Y.Y. Li, Effect of sintering temperature on the preparation of Cu-Ti3SiC2 metal matrix composite, Prog. Nat. Sci.: Mater. Int., 23(2013, No. 1, p. 70.

Y. Zhou, B. Chen, X. Wang, and C. Yan, Mechanical properties of Ti3SiC2 particulate reinforced copper prepared by hot pressing of copper coated Ti3SiC2 and copper powder, Mater. Sci. Technol., 20(2004, No. 5, p. 661.

S. Wang, S.Y. Zhu, J. Cheng, Z.H. Qiao, J. Yang, and W.M. Liu, Microstructural, mechanical and tribological properties of Al matrix composites reinforced with Cu coated Ti3AlC2, J. Alloys Compd., 690(2017), p. 612.

B.Y. Guan, X. Wang, Y. **ao, Y.L. Liu, and Q.S. Huo, A versatile cooperative template-directed coating method to construct uniform microporous carbon shells for multifunctional core-shell nanocomposites, Nanoscale, 5(2013), No. 6, art. No. 2469.

Q. Wang, B.Y. Wang, Z. Zhang, Y. Zhang, J. Peng, Y. Zhang, and H. Wu, Tailoring yolk-shell FeP@carbon nanoboxes with engineered void space for pseudocapacitance-boosted lithium storage, Inorg. Chem. Front., 5(2018, No. 10, p. 2605.

P.X. Huang, S.H. Tang, H. Peng, and X. Li, In situ synthesis of graphitized-carbon coated Li4Ti5O12/C anode for high-rate lithium ion batteries, Mater. Sci. Forum, 814(2015), p. 358.

J. Ding, W.B. Tian, P. Zhang, M. Zhang, Y.M. Zhang, and Z.M. Sun, Arc erosion behavior of Ag/Ti3AlC2 electrical contact materials, J. Alloys Compd., 740(2018), p. 669.

M. Zhang, W.B. Tian, P.G. Zhang, J.X. Ding, Y.M. Zhang, and Z.M. Sun, Microstructure and properties of Ag-Ti3SiC2 contact materials prepared by pressureless sintering, Int. J. Miner. Metall. Mater., 25(2018, No. 7, p. 810.

D.D. Wang, W.B. Tian, A.B. Ma, J.X. Ding, C.S. Wang, Y.Y. You, P.G. Zhang, J. Chen, Y.M. Zhang, and Z.M. Sun, Anisotropic properties of Ag/Ti3AlC2 electrical contact materials prepared by equal channel angular pressing, J. Alloys Compd., 784(2019), p. 431.

L.M. Pan, J. Gu, W.J. Zou, T. Qiu, H.B. Zhang, and J. Yang, Brazing joining of Ti3AlC2 ceramic and 40Cr steel based on Ag-Cu-Ti filler metal, J. Mater. Process. Technol., 251(2018), p. 181.

M.M. Liu, J.L. Chen, H. Cui, X.D. Sun, S.H. Liu, and M. **e, Ag/Ti3AlC2 composites with high hardness, high strength and high conductivity, Mater. Lett., 213(2018), p. 269.

Acknowledgements

The authors acknowledge the financial support of the National Natural Science Foundation of China (Nos. 51731004 and 51671054), the Natural Science Foundation of Jiangsu Province (No. BK20181285), and the Fundamental Research Funds for the Central Universities, China (No. 2242019K 40056).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zhu, Yf., Tian, Wb., Wang, Dd. et al. Fabrication and properties of silver-based composites reinforced with carbon-coated Ti3AlC2. Int J Miner Metall Mater 28, 1836–1843 (2021). https://doi.org/10.1007/s12613-020-2064-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-020-2064-6