Abstract

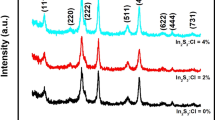

Nanomultilayered TiN/Ni thin films with different bilayer periods (57.8–99.7 nm) and Ni single-layer thickness (3.9–19.2 nm) were prepared by alternatively sputtering Ti and Ni targets in N2 gas atmosphere. The microstructure, mechanical and corrosion properties of the multilayer films were investigated by X-ray diffraction (XRD), field emission scanning electron microscopy (FESEM), X-ray photoelectron spectroscopy (XPS), nanoindenter and electrochemical technologies. The multilayer films are fine with a mean grain size of ~ 8–9 nm independent of the bilayer period. However, the smoothness and compactness seem to decrease with the bilayer period increasing. The hardness (H) and elastic modulus (E) of the multilayer films gradually decrease as the bilayer period increases, and the multilayer film with bilayer period of 57.8 nm exhibits higher H, ratios of \( (H/E^{*} \,\,{\text{and}}\,\,H^{3} /E^{*2} ) \) (\( E^{*} \) is effective Young’s modulus) than the monolithic TiN film and the other multilayers. The multilayer films exhibit an obvious passivation phenomenon in 10% H2SO4 solution, and the passive current and corrosion current densities decrease, whereas the corrosion potential increases when the bilayer period or Ni single-layer thickness decreases. It is found that the passivating behavior and corrosion potential of the multilayers are more sensitive to Ni single-layer thickness than the bilayer period. More corrosion pits and lamellar flaking could be found on the films with larger bilayer period or Ni single-layer thickness.

Similar content being viewed by others

References

Zhou FZ, Fu KH, Zhang X, Liao B, Yu JJ. Compositional, structural and mechanical characteristics of nc-ZrCN/a-CNx films with different flows of C2H2/N2 gas. Chin J Rare Met. 2015;39(12):1083.

Yang GY, Peng H, Guo HB, Gong SK. Deposition of TiN/TiAlN multilayers by plasma-activated EB-PVD: tailored microstructure by jum** beam technology. Rare Met. 2017;36(8):651.

Wang T, Zhang G, Jiang B. Comparison in mechanical and tribological properties of CrTiAlMoN and CrTiAlN nano-multilayer coatings deposited by magnetron sputtering. Appl Surf Sci. 2016;363:217.

Wang YX, Zhang S, Lee JW, Lew WS, Li B. Toughening effect of Ni on nc-CrAlN/a-SiNx hard nanocomposite. Appl Surf Sci. 2013;265:418.

Yu X, Meng H, Wang CB, Fu ZQ, Liu Y. Investigation of Ti/TiN multilayered films in a reactive mid-frequency dual-magnetron sputtering. Appl Surf Sci. 2007;253(7):3705.

Chen CZ, Li Q, Leng YX, Chen JY, Zhang PC, Bai B, Huang N. Improved hardness and corrosion resistance of iron by Ti/TiN multilayer coating and plasma nitriding duplex treatment. Surf Coat Technol. 2010;204(18–19):3082.

Zhang Q, Leng YX, Qi F, Tao T, Huang N. Mechanical and corrosive behavior of Ti/TiN multilayer films with different modulation periods. Nucl Instrum Methods Phys Res B. 2007;257(1–2):411.

Flores M, Muhl S, Huerta L, Andrade E. The influence of the period size on the corrosion and the wear abrasion resistance of TiN/Ti multilayers. Surf Coat Technol. 2005;200(5–6):1315.

Yang W, Ayoub G, Salehinia I, Mansoor B, Zbib H. Deformation mechanisms in Ti/TiN multilayer under compressive loading. Acta Mater. 2017;122:99.

Marulanda DM, Olaya JJ, Piratoba U, Mariño A, Camps E. The effect of bilayer period and degree of unbalancing on magnetron sputtered Cr/CrN nano-multilayer wear and corrosion. Thin Solid Films. 2011;519(6):1886.

Romero J, Esteve J, Lousa A. Period dependence of hardness and microstructure on nanometric Cr/CrN multilayers. Surf Coat Technol. 2004;188–189:338.

Song GH, Luo Z, Li F, Chen LJ, He CL. Microstructure and indentation toughness of Cr/CrN multilayer coatings by arc ion plating. Trans Nonferrous Met Soc China. 2015;25(3):811.

Song GH, Yang XP, **ong GL, Lou Z, Chen LJ. The corrosive behavior of Cr/CrN multilayer coatings with different modulation periods. Vacuum. 2013;89:136.

Söderlund E, Ljunggren P. Formability and corrosion properties of metal/ceramic multilayer coated strip steels. Surf Coat Technol. 1998;110(1–2):94.

Kim YJ, Byun TJ, Lee HY, Han JG. Effect of bilayer period on CrN/Cu nanoscale multilayer thin films. Surf Coat Technol. 2008;202(2–3):5508.

Wei CB, Tian XB, Yang Y, Yang SQ, Fu RKY, Chu PK. Microstructure and tribological properties of Cu–Zn/TiN multilayers fabricated by dual magnetron sputtering. Surf Coat Technol. 2007;202(1):189.

Vladescu A, Braic V, Braic M, Balaceanu M. Arc plasma deposition of TiSiN/Ni nanoscale multilayered coatings. Mater Chem Phys. 2013;138(2–3):500.

Ge FF, Zhou XJ, Meng FP, Xue QJ, Huang F. Tribological behavior of VC/Ni multilayer coatings prepared by non-reactive magnetron sputtering. Tribol Int. 2016;99:140.

Chu X, Wong MS, Sproul WD, Barnett SA. Mechanical properties and microstructures of polycrystalline ceramic/metal superlattices: TiN/Ni and TiN/Ni0.9Cr0.1. Surf Coat Technol. 1993;61(1–3):251.

Zhang GJ, Wang T, Chen HL. Microstructure, mechanical and tribological properties of TiN/Mo2N nano-multilayer films deposited by magnetron sputtering. Surf Coat Technol. 2015;261:156.

Huang JH, Ma CH, Chen H. Effect of Ti interlayer on the residual stress and texture development of TiN thin films deposited by unbalanced magnetron sputtering. Surf Coat Technol. 2006;201(6):3199.

Akbari A, Riviere JP, Templier C, Bourhis EL. Structural and mechanical properties of IBAD deposited nanocomposite Ti–Ni–N coatings. Surf Coat Technol. 2006;200(22–23):6298.

Regent F, Musil J. Magnetron sputtered Cr–Ni–N and Ti–Mo–N films: comparison of mechanical properties. Surf Coat Technol. 2001;142–144:146.

He CL, Zhang JL, Wang JM, Ma GF, Zhao DL, Cai QK. Effect of structural defects on corrosion initiation of TiN nanocrystalline films. Appl Surf Sci. 2013;276:667.

Barshilia HC, Prakash MS, Poojari A, Rajam KS. Corrosion behavior of nanolayered TiN/NbN multilayer coatings prepared by reactive direct current magnetron sputtering process. Thin Solid Films. 2004;460(1–2):133.

Patsalas P, Charitidis C, Logothetidis S. The effect of substrate temperature and biasing on the mechanical properties and structure of sputtered titanium nitride thin films. Surf Coat Technol. 2000;125(1–3):335.

**ao LS, Yan DR, He JN, Zhu L, Dong YC, Zhang JX, Li XZ. Nanostructured TiN coating prepared by reactive plasma spraying in atmosphere. Appl Surf Sci. 2007;253(18):7535.

Vaz F, Machado P, Rebouta L, Cerqueira P, Goudeau Ph, Rivière JP, Alves E, Pischow K. Rijk Jde. Mechanical characterization of reactively magnetron-sputtered TiN films. Surf Coat Technol. 2003;174–175:375.

Rong SQ, He J, Wang HJ, Tian CX, Guo LP, Fu DJ. Effects of bias voltage on the structure and mechanical properties of thick CrN coatings deposited by mid-frequency magnetron sputtering. Plasma Sci Technol. 2009;11(1):38.

VNIoSaT. NIST X-ray Photoelectron Spectroscopy Database. Gaithersburg: National Institute of Standards and Technology; 2012. 1.

Barshilia HC, Rajam KS. Structure and properties of reactive DC magnetron sputtered TiN/NbN hard superlattices. Surf Coat Technol. 2004;183(2–3):174.

Devia DM, Restrepo-Parra E, Arango PJ, Tschiptschin AP, Velez JM. TiAlN coatings deposited by triode magnetron sputtering varying the bias voltage. Appl Surf Sci. 2011;257(14):6181.

Musil J. Physical and mechanical properties of hard nanocomposite films prepared by reactive magnetron sputtering. In: Cavaleiro A, De Hosson JThM, editors. Nanostructured Coatings. New York: Springer; 2006. 407.

Zhang LQ, Yang HS, Pang XL, Gao KW, Volinsky AA. Microstructure, residual stress, and fracture of sputtered TiN films. Surf Coat Technol. 2013;224:120.

Tsui TY, Pharr GM, Oliver WC, Bhatia CS, White RL, Anders S, Anders A, Brown IG. Nanoindentation and nanoscratching of hard carbon coatings for magnetic disks. Mater Res Soc Symp Proc. 1995;383:447.

Musil J, Kunc F, Zeman H, Polakova H. Relationships between hardness, Young’s modulus and elastic recovery in hard nanocomposite coatings. Surf Coat Technol. 2002;154(2–3):304.

Nam ND, Kim JG, Hwang WS. Effect of bias voltage on the electrochemical properties of TiN coating for polymer electrolyte membrane fuel cell. Thin Solid Films. 2009;517(17):4772.

Franco CV, Fontana LC, Bechl D, Martinelli AE, Muzart JLR. An electrochemical study of magnetron sputtered Ti- and TiN-coated steel. Corros Sci. 1998;40(1):103.

William Grips VK, Barshilia HC, Ezhil Selvi V, Kalavati Rajam KS. Electrochemical behavior of single layer CrN, TiN, TiAlN coatings and nanolayered TiAlN/CrN multilayer coatings prepared by reactive direct current magnetron sputtering. Thin Solid Films. 2006;514(1–2):204.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 51171118).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

He, CL., Zhang, JL., **e, LP. et al. Microstructure, mechanical and corrosion properties of TiN/Ni nanomultilayered films. Rare Met. 38, 979–988 (2019). https://doi.org/10.1007/s12598-018-1154-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-018-1154-3