Abstract

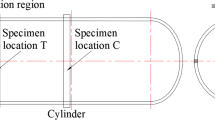

As air pollution becomes more severe, the use of clean energy in vehicles is an inevitable requirement and it is leading the development of automotive industries. Especially, hydrogen-fueled vehicles require safe and lightweight high pressure storage vessels to carry enough amounts of hydrogen gas. To develop mechanically robust and lightweight high pressure vessel, it is of significance to establish design and manufacturing process for liners and carbon fiber reinforced plastics layers. In this study, to design a composite layer in a high pressure hydrogen vessel (Type 4), a calculation method of stress generated in each ply by applying the CLT (Classical Laminate Theory) is proposed. And based on the calculation method, we carried out the composite layer design in the hydrogen high pressure vessel (Type 4) that can satisfy the requirement for lightweightness and designed the thickness and the pattern of the composite layer with more accuracy than the netting theory and with more rapid than FEA.

Similar content being viewed by others

References

Nonobe, Y. (2017). Development of the fuel cell vehicle mirai. IEEJ Transactions of Electrical and Electronic Engineering, 12(1), 5–9.

Panwar, N. L., Kaushik, S. C., & Kothari, S. (2011). Role of renewable energy sources in environmental protection: A review. Renewable and Sustainable Energy Reviews, 15(3), 1513–1524.

Ball, M., & Weeda, M. (2015). The hydrogen economy-vision or reality? Compendium of Hydrogen Energy, 40(25), 7903–7919.

Kim, K., & Kwon, T. K. (2020). Characteristics of temperature-pressure of metal-hydride actuation system using hydrogen pressure change. International journal of Precision Engineering and Manufacturing, 21(9), 1763–1770.

Kim, M. S., Lee, J. H., & Kwak, M. K. (2020). Review : Surface texturing methods for solar cell efficiency enhancement. International Journal of Precision Engineering and Manufacturing, 21(7), 1389–1398.

Rahim, A., Tijani, A., Mohamed, W., Hanapi, S., & Sainan, K. (2015). An overview of hydrogen production from renewable energy soruce for remote area application. Applied Mechanics and Materials, 699, 474–479.

John, J., Kast, J., Morrison, G., & Marcinkoski, J. (2017). Design space assessment of hydrogen storage onboard medium and heavy duty fuel cell electric trucks. Journal of Electrochemical Energy Conversion and Storage, 14(2), 021004.

Li, W., Ye, J., Cui, Y., Kim, N., Cha, S. W., & Zheng, C. (2022). A speed reinforcement learning-based energy management strategy for fuel cell hybrid vehicles considering fuel cell system lifetime. International Journal of Precision Engineering and Manufacturing-Green Technology, 9(5), 859–872.

Lv, H., Shen, G., Yu, Y., Zhu, L., & Zhou, R. (2021). Defect detection in the winding layer of CNG composite-wound Cylindersvrture of minimal mechanism is that it allows. International Journal of Precision Engineering and Manufacturing, 22(12), 1937–1946.

Zheng, C., Li, W., Li, W., Xu, K., Peng, L., & Cha, S. W. (2022). A deep reinforcement learning-based energy management strategy for fuel cell hybrid buses. International Journal of Precision Engineering and Manufacturing-Green Technology, 9(5), 885–897.

Barthelemy, H., Weber, M., & Barbier, F. (2017). Hydrogen storage : Recent improvements and industrial perspectives. International Journal of Hydrogen Energy, 42(11), 7254–7262.

Humberto, J., Almeida, S., Faria, H., Marques, T., & Amico, C. (2014). Load sharing ability of the liner in type III composite pressure vessels under internal pressure. Journal of Reinforced Plastics & Composites, 33(24), 2274–2286.

Musthak, M. D., Madar, P., & Narayana, S. (2016). Prediction of transverse directional strains and stresses of filament wound composite pressure vessel by using higher order shear deformation theories. International Journal of Composite Materials, 6(3), 79–87.

Cho, S. M., Kim, K. S., Lee, S. K., Jung, G. S., Lee, S. K., & Lyu, S. K. (2018). Effect of dome curvature on failure mode of type 4 composite pressure vessel. International Journal of Precision Engineering and Manufacturing, 19(3), 405–410.

Sapre, S., Pareek, K., & Vyas, M. (2020). Investigation of structural stability of type IV compressed hydrogen storage tank during refueling of fuel cell vehicle. Journal of Energy Storage, 2(4), e150.

Alcantar, V., Aceves, S. M., Ledesma, E., Ledesma, E., Ledesma, S., & Aguilera, E. (2017). Optimization of Type 4 composite pressure vessels using genetic algorithms and simulated annealing. International Journal of Hydrogen Energy, 42(24), 15770–15781.

Hua, T. Q., Roh, H. S., & Ahluwalia, R. K. (2017). Performance assessment of 700-bar compressed hydrogen storage for light duty fuel cell vehicles. International Journal of Hydrogen Energy, 42(40), 25121–25129.

Leh, D., Saffre, P., Francescato, P., Arrieux, R., & Villalonga, S. (2015). A progressive failure analysis of a 700-bar type IV hydrogen composite pressure vessel. International Journal of Hydrogen Energy, 40(38), 13206–13214.

Jois, K. C., Welsh, M., Gries, T., & Sackmann, J. (2021). Numerical analysis of filament wound cylindrical composite pressure vessels accounting for variable dome contour. Journal of Composites Science, 5(2), 56–71.

Zhang, Q., Xu, H., Jia, X., Zu, L., Cheng, S., & Wang, H. (2020). Design of a 70 MPa type IV hydrogen storage vessel using accurate modeling techniques for dome thickness prediction. Composite Structures, 236(3), 111915–111925.

**a, M., Takayanagi, H., & Kemmochi, K. (2001). Analysis of multi-layered filament wound composite pipes under internal pressure. Composite Structures, 53(4), 483–491.

Cetin, M., & Yaman, K. (2020). Location size and orientation effect of semi-elliptical surface crack on the fracture of a type-3 composite pressure vessel using J-integral method. Defence Science Journal, 70(1), 23–34.

Parnas, L., & Katirci, N. (2002). Design of fiber-reinforced composite pressure vessels under various loading conditions. Composite Structures, 58(1), 83–95.

Park, G. Y., Jang, H. S., & Kim, C. (2021). Design of composite layer and liner for structure safety of hydrogen pressure vessel (type 4). Journal of Mechanical Science and Technology, 35(8), 3507–3517.

Solazzi, L., & Vaccari, M. (2022). Reliability design of a pressure vessel made of composite materials. Composite Structures, 279(1), 114726–114737.

Daghia, F., Baranger, E., Tran, D. T., & Pichon, P. (2020). A hierarchy of models for the design of composite pressure vessels. Composite Structures, 235(1), 111809–111827.

Son, D. S., & Chang, S. H. (2021). Evaluation of modeling techniques for a type III hydrogen pressure vessel (70 MPa) made of an aluminum liner and a thick carbon/epoxy composite for fuel cell vehicles. International Journal of Hydrogen Energy, 37(3), 2353–2369.

Acknowledgements

This work was supported by Materials/Parts Technology Development Program (No. 20015893) funded By the Ministry of Trade, industry & Energy(MI, Korea).

Author information

Authors and Affiliations

Contributions

Both authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interest

The authors declare no competing financial interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Park, G., Kim, C. Composite Layer Design Using Classical Laminate Theory for High Pressure Hydrogen Vessel (Type 4). Int. J. Precis. Eng. Manuf. 24, 571–583 (2023). https://doi.org/10.1007/s12541-022-00752-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-022-00752-w