Abstract

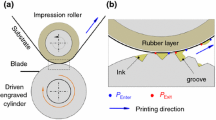

A curing process as a post-treatment of roll-to-roll (R2R) printing is designed to form a functionality of printed pattern such as conductivity when devices e.g., radio frequency identification, fuel cell, display, and flexible printed circuits board are fabricated by solution-based printing process. Polyethylene naphthalate (PEN) as well as polyethylene terephthalate (PET), which were employed as a flexible substrate, would be stretched much in the post-treatment process due to reduced elastic modulus in high temperature. The elongation of substrate generates cracks inside the printed layer. The formation of crack triggers increasing in electrical resistance and deteriorating in the performance of the device. Therefore, the elongation of substrate should be minimized considering the variations of conductivity of printed layer during the R2R process. In this study, a mathematical model for the relationship among the operating tension, the temperature, and the conductivity of printed layer was developed. The deterioration of conductivity was investigated by observation of cracks in printed layer. The conductivity of printed layer on the stretched substrate was estimated by the proposed model. Also, operating tension was determined for guarantying conductivity even in various temperatures for posttreatment process.

Similar content being viewed by others

References

Park, Y. J. and Lee, G. B., “Analysis of Energy Efficiency and Productivity in Dry Process in PCB Manufacturing,” Int. J. Precis. Eng. Manuf., Vol. 14, No. 7, pp. 1213–1221, 2013.

Zhao, K., Liu, Z., Wang, Y., and Jiang, H., “Study on Recycling Process for EOL Liquid Crystal Display Panel,” Int. J. Precis. Eng. Manuf., Vol. 14, No. 6, pp. 1043–1047, 2013.

Ji, S., Hwang, Y. S., Park, T., Lee, Y. H., Paek, J. Y., et al., “Graphite Foil based Assembled Bipolar Plates for Polymer Electrolyte Fuel Cells,” Int. J. Precis. Eng. Manuf., Vol. 13, No. 12, pp. 2183–2186, 2012.

Kim, M. S., Shin, H. J., and Park, Y. K., “Design Concept of High-Performance Flexible Tactile Sensors with a Robust Structure,” Int. J. Precis. Eng. Manuf., Vol. 13, No. 11, pp. 1941–1947, 2012.

Lee, C., Kang, H., Kim, C., and Shin, K., “A Novel Method to Guarantee the Specified Thickness and Surface Roughness of the Roll-to-Roll Printed Patterns using the Tension of a Moving Substrate,” Journal of Microelectromechanical Systems, Vol. 19, No. 5, pp. 1243–1253, 2010.

Lee, C., Kang, H., and Shin, K., “Advanced Taper Tension Method for the Performance Improvement of a Roll-to-Roll Printing Production Line with a Winding Process,” International Journal of Mechanical Sciences, Vol. 59, No. 1, pp. 61–72, 2012.

Nguyen, H.-A.-D., Lee, C., and Shin, K.-H., “A Mathematical Model to Predict Surface Roughness and Pattern Thickness in Rollto-roll Gravure Printed Electronics,” Robotics and Computer-Integrated Manufacturing, Vol. 29, No. 4, pp. 26–32, 2013.

Kang, H., Park, J., and Shin, K., “Statistical Analysis for the Manufacturing of Multi-Strip Patterns by Roll-to-Roll Single Slot- Die Systems,” Robotics and Computer-Integrated Manufacturing, Vol. 30, No. 4, pp. 363–368, 2014.

Kang, H., Lee, C., and Shin, K., “Modeling and Compensation of the Machine Directional Register in Roll-to-Roll Printing,” Control Engineering Practice, Vol. 21, No. 5, pp. 645–654, 2013.

Kang, H., Lee, C., and Shin, K., “A Novel Cross Directional Register Modeling and Feedforward Control in Multi-Layer Roll-to-Roll Printing,” Journal of Process Control, Vol. 20, No. 5, pp. 643–652, 2010.

Kang, H., Sowade, E., and Baumann, R. R., “Direct Intense Pulsed Light Sintering of Inkjet-Printed Copper Oxide Layers within Six Milliseconds,” ACS Applied Materials & Interfaces, Vol. 6, No. 3, pp. 1682–1687, 2014.

Unold, T. and Schock, H., “Nonconventional (Non-Silicon-based) Photovoltaic Materials,” Annual Review of Materials Research, Vol. 41, pp. 297–321, 2011.

Knox, K. L. and Sweeney, T. L., “Fluid Effects Associated with Web Handling,” Industrial & Engineering Chemistry Process Design and Development, Vol. 10, No. 2, pp. 201–206, 1971.

Ducotey, K. S. and Good, J. K., “The Effect of Web Permeability and Side Leakage on the Air Film Height between a Roller and Web,” Journal of Tribology, Vol. 120, No. 3, pp. 559–565, 1998.

Hashimoto, H., “Air Film Thickness Estimation in Web Handling Processes,” Journal of Tribology, Vol. 121, No. 1, pp. 50–55, 1999.

Ducotey, K. S. and Good, J. K., “Predicting Traction in Web Handling,” Journal of Tribology, Vol. 121, No. 3, pp. 618–624, 1999.

Hannebauer, H., Dullweber, T., Falcon, T., and Brendel, R., “Fineline Printing Options for High Efficiencies and low Ag Paste Consumption,” Energy Procedia, Vol. 38, No. pp. 725–731, 2013.

Nambiar, S. and Yeow, J. T., “Conductive Polymer-based Sensors for Biomedical Applications,” Biosensors and Bioelectronics, Vol. 26, No. 5, pp. 1825–1832, 2011.

Arlinghaus, S., “Practical Handbook of Curve Fitting,” CRC Press, pp. 83–106, 1994.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kang, H., Lee, C. Effect of tension on conductivity of gravure printed Ag layer in roll-to-roll process. Int. J. Precis. Eng. Manuf. 16, 99–104 (2015). https://doi.org/10.1007/s12541-015-0012-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-015-0012-6