Abstract

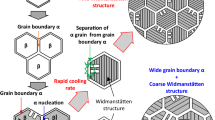

The cooling time of cryogenic vaporised Ar shielding/cooling of Ti-6Al-4 V deposits was ~ 10 times faster than that of normal Ar gas shielding/cooling. The columnar β grains in rapid cooling condition were observed to be in the longitudinal direction of the deposits same as that in natural cooling condition. Under the rapid cooling, a narrow heat-affected zone band (~ 70 μm) and a wide vanadium-segregation band was observed, along with a reduced aspect ratio of the α plate, which led to improved isotropic-tensile properties along the deposition and building directions. Rapid cooling condition also retained a significant amount of O and N, which enhanced its hardness and tensile strength. Thus, cryogenic vaporised Ar shielding/cooling can produce Ti-6Al-4 V wire-arc additive manufacturing deposits with better tensile properties compared to normal Ar gas shielding.

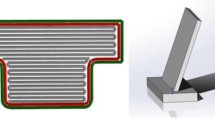

Graphical abstract

Similar content being viewed by others

References

D. Herzog, V. Seyda, E. Wycisk, C. Emmelmann, Acta Mater. 117, 371 (2016)

J. Ran, F. Jiang, Z. Chen, H. Zhao, Met. Mater. Int. 28, 770 (2022)

T.A. Rodrigues, V. Duarte, R.M. Miranda, T.G. Santos, J.P. Oliveira, Materials 12, 1121 (2019)

M.D. Barath Kumar, M. Manikandan, Met. Mater. Int. 28, 54 (2022)

N. Huda, J.W. Kim, C. Ji, D.-G. Nam, Y.-D. Park, J. Weld. Join. 39, 81 (2021)

S.-H. Jeon, T.-W. Kim, Y.-W. Lee, Y.-C. Kim, J. Weld. Join. 39, 632 (2021)

N. Knezović, A. Topić, in New Technologies, Development and Application, ed. by I. Karabegović. 4th International Conference on New Technologies and Applications (NT-2018), Sarajevo, Bosnia and Herzegovina, 28–30 June 2018. Lecture Notes in Networks and Systems, vol. 42 (Springer, Cham, 2019), pp. 65–71

C.R. Cunningham, J.M. Flynn, A. Shokrani, V. Dhokia, S.T. Newman, Addit. Manuf. 22, 672 (2018)

N. Kozamernik, D. Bračun, D. Klobčar, Int. J. Adv. Manuf. Technol. 110, 1955 (2020)

W. Hackenhaar, J.A.E. Mazzaferro, F. Montevecchi, G. Campatelli, J. Manuf. Process. 52, 58 (2020)

S. Pattanayak, S.K. Sahoo, CIRP J. Manuf. Sci. Technol. 33, 398 (2021)

H.-J. Yi, J.-W. Kim, Y.-L. Kim, S. Shin, Met. Mater. Int. 26, 1235 (2020)

Y. Fu, N. Guo, G. Wang, M. Yu, Q. Cheng, D. Zhang, Mater. Design 197, 109196 (2021)

T.S. Byun, M.N. Gussev, T.G. Lach, M. Li, X. Zhang, M.R. McAlister, J.J. Simpson, B.E. Garrison, Y. Yamamoto, C.B. Joslin, J.K. Carver, F.A. List, R.R. Dehoff, K.A. Terrani, Mechanical Properties and Deformation Behavior of Additively Manufactured 316L Stainless Steel – FY 2020, ORNL/TM-2020/1574, Technical Report (Oak Ridge National Lab. (ORNL), Oak Ridge, 2020)

G. **an, J.M. Oh, J. Lee, S.M. Cho, J.-T. Yeom, Y. Choi, N. Kang, Weld. World 66, 847 (2022)

S.M. Kelly, Thermal and microstructure modeling of metal deposition processes with application to Ti-6Al-4V, Ph. D. thesis, Virginia Polytechnic Institute and State University (2004)

A. Ho, H. Zhao, J.W. Fellowes, F. Martina, A.E. Davis, P.B. Prangnell, Acta Mater. 166, 306 (2019)

S.A. David, J.M. Vitek, Int. Mater. Rev. 34, 213 (1989)

V.D. Fachinotti, A. Cardona, B. Baufeld, O. Van der Biest, Acta Mater. 60, 6621 (2012)

J.W. Elmer, T.A. Palmer, S.S. Babu, W. Zhang, T. DebRoy, J. Appl. Phys. 95, 8327 (2004)

S. Kou, Welding Metallurgy, 2nd edn. (John Wiley & Sons, New York, 2003)

D. Nursyifaulkhair, N. Park, E.R. Baek, J. Weld. Join. 39, 527 (2021)

T.F. Broderick, A.G. Jackson, H. Jones, F.H. Froes, Metall. Trans. A 16, 1951 (1985)

A.A. Antonysamy, Microstructure, texture and mechanical property evolution during additive manufacturing of Ti6Al4V alloy for aerospace applications, Ph.D. thesis, The University of Manchester (2012)

L. Liu, C. Chen, R. Zhao, X. Wang, H. Tao, S. Shuai, J. Wang, H. Liao, Z. Ren, Addit. Manuf. 46, 102142 (2021)

M. Yan, W. Xu, M.S. Dargusch, H.P. Tang, M. Brandt, M. Qian, Powder Metall. 57, 251 (2014)

C. Pauzon, K. Dietrich, P. Forêt, S. Dubiez-Le Goff, E. Hryha, G. Witt, Addit. Manuf. 38, 101765 (2021)

G. Zhang, X. Lu, J. Li, J. Chen, X. Lin, M. Wang, H. Tan, W. Huang, Addit. Manuf. 55, 102865 (2022)

B.E. Carroll, T.A. Palmer, A.M. Beese, Acta Mater. 87, 309 (2015)

M.J. Donachie, Titanium: A Technical Guide, 2nd edn. (ASM International, Materials Park, 2000)

K.M. Bertsch, T. Voisin, J.B. Forien, E. Tiferet, Y.I. Ganor, M. Chonin, Y.M. Wang, M.J. Matthews, Mater. Design 216, 110533 (2022)

Y. Han, X. Yang, W. Zeng, W. Lu, Int. J. Mod. Phys. B. 29, 1540012 (2015)

Acknowledgements

This work was supported in part by the Ministry of Science, ICT, and Future Planning of Korea through the National Research Foundation of Korea (NRF) Future Material Discovery Project (NRF-2016M3D1A1023534) and by the Ministry of Trade, Industry and Energy (MOTIE, Korea) through the Technology Innovation Program (20004932).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

**an, G., Cheepu, M., Yu, J. et al. Enhancing Tensile Properties of Wire-Arc Additively Manufactured Ti-6Al-4 V Deposits Via Cryogenic Vaporised Ar Shielding/Cooling. Met. Mater. Int. 29, 501–514 (2023). https://doi.org/10.1007/s12540-022-01272-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-022-01272-y