Abstract

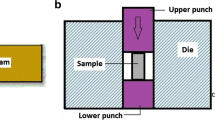

In this study, aluminum/alumina composites with 3 and 5 vol% reinforcement particles were manufactured via stir casting and hot forging; they were severely deformed by the simple shear extrusion (SSE) technique. Three SSE dies with different distortion angles were utilized in this work. The SSE-ed samples with α = 22.5° were then fractured after one pass, while SSE-ed samples with α = 8 and 10° were deformed up to thirteen passes, successfully. Microstructural evolution, porosity percentage and micro hardness parameters were investigated after each process. Shear punch test was then used to evaluate the mechanical properties. Additionally, the applied force and stress/strain distributions were evaluated by the finite element method (FEM) code via ABAQUS® simulation software in different passes. Moreover, the effect of the SSE process on the fracture behavior of the commercial Al and aluminum matrix composite was studied. The results showed that the effective strain was increased with increasing the number of SSE passes and distortion angles, while the applied force was decreased with increasing the number of passes. Microstructure, bonding quality, hardness and porosity percentage were also improved by using forging and SSE processes. During the process, ultimate shear strength was enhanced with increasing the amounts of effective strain; also, shear elongation percentage was decreased. Further, SEM observations showed that the fracture mode in the SSE-ed commercial Al sample was a typical ductile one, whereas the fracture mode was nearly shear ductile with more flat surfaces in the Al-5 vol% Al2O3 specimens.

Graphical Abstract

Similar content being viewed by others

References

K.V. Reddy, R.B. Naik, G.R. Rao, G.M. Reddy, R.A. Kumar, Compos. Commun. 20, 100352 (2020). https://doi.org/10.1016/j.coco.2020.04.018

A. Shabani, M.R. Toroghinejad, J. Mater. Eng. Perform. 27, 6004 (2018). https://doi.org/10.1007/s11665-018-3692-0

T. Vogel, S. Ma, Y. Liu, Q. Guo, D. Zhang, Compos. Commun. 22, 100462 (2020). https://doi.org/10.1016/j.coco.2020.100462

A. Macke, B.F. Schultz, P. Rohatgi, Adv. Mater. Process 170, 19 (2012)

J.L.H. Rivera, J.J.C. Rivera, V.P.D. Ángel, V.G. Febles, O.C. Alonso, R. Martínez-Sánchez, Mater. Des. 37, 96 (2012). https://doi.org/10.1016/j.matdes.2011.12.035

W.B. Yu, Z.H. Yuan, Z.P. Guo, S.M. **ong, Trans. Nonferrous Met. Soc. China. 27, 2529 (2017). https://doi.org/10.1016/S1003-6326(17)60281-4

P. Samal, P.R. Vundavilli, A. Meher, M.M. Mahapatra, J. Manuf. Process. 59, 131 (2020). https://doi.org/10.1016/j.jmapro.2020.09.010

A. Mohan, K.S. Sajikumar, Mater. Today: Proc. 46, 9508 (2020). https://doi.org/10.1016/j.matpr.2020.03.711

M. Zabihi, M.R. Toroghinejad, A. Shafyei, Mater. Sci. Eng. A 560, 567 (2013). https://doi.org/10.1016/j.msea.2012.09.103

D. Rajesh, P. Anand, N. Lenin, V.K.B. Raja, K. Palanikumar, V. Balaji, Mater. Today: Proc. 46, 3618 (2021). https://doi.org/10.1016/j.matpr.2021.01.634

J.M. Mistry, P.P. Gohil, Compos. B. Eng. 161, 190 (2019). https://doi.org/10.1016/j.compositesb.2018.10.074

R. Casati, Aluminum Matrix Composites Reinforced with Alumina Nanoparticles, (Springer International Publishing, Springer Briefs in Applied Sciences and Technology 2015), p 126.

R.Z. Valiev, J. Mater. Sci. 42, 1483 (2007). https://doi.org/10.1007/s10853-006-1281-3

E. Bagherpour, F. Qods, R. Ebrahimi, H. Miyamoto, Mater. Sci. Eng. A 674, 221 (2016). https://doi.org/10.1016/j.msea.2016.08.001

R. Ebrahimi, A. Rezvani, E. Bagherpour, Procedia Manuf. (2018). https://doi.org/10.1016/j.promfg.2018.07.328

N. Pardis, R. Ebrahimi, Mater. Sci. Eng. A 527, 355 (2009). https://doi.org/10.1016/j.msea.2009.08.051

E. Bagherpour, F. Qods, R. Ebrahimi, H. Miyamoto, Mater. Sci. Eng. A 666, 324 (2016). https://doi.org/10.1016/j.msea.2016.04.080

M. Zabihi, M.R. Toroghinejad, A. Shafyei, Mater. Sci. Eng. A 618, 490 (2014). https://doi.org/10.1016/j.msea.2014.09.037

M. Zabihi, E. Emadoddin, F. Qods, Met. Mater. Int. 26, 1 (2020). https://doi.org/10.1007/s12540-019-00299-y

ABAQUS™/CAE User's Manual. Dassault Systems. ABAQUS™ Ver. 6.14

S. Amirkhanlou, R. Jamaati, B. Niroumand, M.R. Toroghinejad, Mater. Sci. Eng. A 528, 4462 (2011). https://doi.org/10.1016/j.msea.2011.02.037

EN 13925-1, Non-destructive testing. X-ray diffraction from polycrystalline and amorphous materials General principles (European Committee for Standardization (CEN), Brussels, 2003)

ASTM E384-17, Standard Test Method for Microindentation Hardness of Materials (ASTM International, West Conshohocken, 2017)

M.B. Toloczko, M.L. Hamilton, G.E. Lucas, Proceedings of the IEA International Symposium, United States of America (1996)

W. Shuo, F. Min, L. **, J. Mater. Process. Technol. 255, 105 (2018). https://doi.org/10.1016/j.jmatprotec.2017.12.008

H. Liao, Y. Sun, G. Sun, Mater. Sci. Eng. A 335, 62 (2002). https://doi.org/10.1016/S0921-5093(01)01949-9

F.V. Lenel, Powder Metallurgy: Principles and Applications, 1st edn. (Metal Powder Industries Federation, Princeton, 1980), p. 128

R. Derakhshandeh-Haghighi, S.A. Jenabali Jahromi, J. Mater. Eng. Perform. 25, 687 (2016) https://doi.org/10.1007/s11665-016-1888-8

N. Pardis, R. Ebrahimi, Mater. Sci. Eng. A 527, 6153 (2010). https://doi.org/10.1016/j.msea.2010.06.028

R. Jamaati, M.R. Toroghinejad, J. Mater. Eng. Perform. 21, 859 (2012). https://doi.org/10.1007/s11665-011-9909-0

R.Z. Valiev, T.G. Langdon, Prog. Mater. Sci. 51, 881 (2006). https://doi.org/10.1016/j.pmatsci.2006.02.003

R. Jamaati, S. Amirkhanlou, M.R. Toroghinejad, B. Niroumand, J. Mater. Eng. Perform. 21, 1249 (2012). https://doi.org/10.1007/s11665-011-0045-7

E. Bagherpour, R. Ebrahimi, F. Qods, Mater. Des. 83, 368 (2015). https://doi.org/10.1016/j.matdes.2015.06.023

N.B. Tork, N. Pardis, R. Ebrahimi, Mater. Sci. Eng. A 560, 34 (2013). https://doi.org/10.1016/j.msea.2012.08.085

E. Bagherpour, M. Reihanian, R. Ebrahimi, Mater. Des. 40, 262 (2012). https://doi.org/10.1016/j.matdes.2012.03.055

S. Deb, S.K. Panigrahi, M. Weiss, Mater. Sci. Eng. A 738, 323 (2018). https://doi.org/10.1016/j.msea.2018.09.101

M. Sarkari Khorrami, N. Saito, Y. Miyashita, M. Kondo, Mater. Sci. Eng. A 744, 349 (2019) https://doi.org/10.1016/j.msea.2018.12.031

M. Zabihi, M.R. Toroghinejad, A. Shafyei, Mater. Sci. Eng. A 667, 383 (2016). https://doi.org/10.1016/j.msea.2016.04.097

S. Kumar, R. Singh, D. Singh, Mater. Today: Proc. 5, 3486 (2018). https://doi.org/10.1016/j.matpr.2017.11.595

A.R. Geranmayeh, R. Mahmudi, M. Kangooie, Mater. Sci. Eng. A 528, 3967 (2011). https://doi.org/10.1016/j.msea.2011.02.034

C.S. Goh, J. Wei, L.C. Lee, M. Gupta, Acta Mater. 55, 5115 (2007). https://doi.org/10.1016/j.actamat.2007.05.032

R. jamaati, S. Amirkhanlou, M.R.Toroghinejad, B. Niroumand, Mater. Sci. Eng. A 528, 2143 (2011) https://doi.org/10.1016/j.msea.2010.11.056

R.K. Guduru, K.A. Darling, R. Scattergood, C.C. Koch, K.L. Murty, J. Mater. Sci. 42, 5581 (2007). https://doi.org/10.1007/s10853-006-1095-3

Acknowledgements

M. Zabihi would like to thank VASEGH FORGE Company for providing die making, hot forging and machining equipment used in this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zabihi, M., Qods, F. & Emadoddin, E. Simple Shear Extrusion of Al/Al2O3 Composite Prepared by Stir Casting and Hot Forging. Met. Mater. Int. 29, 108–125 (2023). https://doi.org/10.1007/s12540-022-01213-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-022-01213-9