Abstract

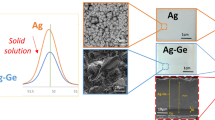

We introduce a cost-effective method that combines electroplating with metal cold working processes to manufacture composite tubes with robust corrosion resistance. First, a 3-step electroplating process was developed to form an adhesive and uniform Ag coating on the outer wall of a 304 stainless steel tube. The process consisted of a Ni-strike step for removing the passivation layer of the initial 304 tube, Cu deposition for smoothing the surface by adding a buffer layer, and Ag deposition. To reinforce the interfacial adhesion between the electroplated layers and the 304 tube and increase the area of the Ag coating, a pilger rolling or pilger rolling + heat-treatment process was performed after the Ag electroplating process. Scanning electron microscopy of the composite tubes after each process indicated that the as-deposited Ag coating changed from having a rough to smooth surface after only pilger rolling and with additional heat treatment. Electron backscatter diffraction analysis of the microstructures and textures of the tubes revealed that dynamic recrystallization occurred extensively during pilger rolling, resulting in the formation of a relatively defect-free grain structure without heat treatment. Furthermore, electrochemical polarization curves determined that the Ag-coated composite tubes are superior to the uncoated 304 tube in terms of corrosion resistance under Cl− atmosphere, owing to the formation of a AgCl passivation layer during testing. Surface analysis of the composite tubes suggests that the properties of the AgCl passivation layer are related to the grain size of the Ag coating and the density of plastic-deformation-induced defects.

Graphic Abstract

Similar content being viewed by others

References

A.J. Sedricks, Corrosion of Stainless Steels, 2nd edn. (Wiley, New York, 1996)

J.R. Davis (ed.), ASM Specialty Handbook: Stainless Steels (ASM International, Materials Park, 1994), pp. 3–132

M. Schlesinger, M. Paunovic, Modern Electroplating The Electrochemical Society INC (Wiley, New Jersey, 2010)

W.H. Safranek, The Properties of Electrodeposited Metals and Alloys, 2nd edn. (American Electroplates and Surface Finishers Society, Orlando, 1986), pp. 99–441

J. Osika, H. Palkowski, K. Świątkowki, D. Pociecha, A. Kula, Arch. Metall. Mater. 54, 1239 (2009)

D. Pletcher, R. Greff, R. Peat, L.M. Peter, J. Robinson, Instrumental Methods in Electrochemistry (Woodhead Publishing Limited, Cambridge, 2011), pp. 15–41

T. Bellezze, G. Giuliani, G. Roventi, Corros. Sci. 130, 113 (2018)

F.J. Humphreys, M. Hatherly, Recrystallization and Related Annealing Phenomena (Pergamon Press, Oxford, 1995)

D.N. Lee, Texture and Related Phenomena, 2nd edn. (The Korean Institute of Metals and Materials, Seoul, 2014), pp. 280–484

S.-J. Kim, H.N. Han, H.-T. Jeong, D.N. Lee, Mater. Res. Innov. 15, s390 (2011)

H.-J. Shin, H.-T. Jeong, D.N. Lee, Mater. Sci. Eng. A 279, 244 (2000)

H. Park, D.N. Lee, Mater. Sci. Forum 408–412, 637 (2002)

W.E. Carscallen, J. Jeswiet, P.H. Oosthuizen, CIRP Ann. Manuf. Technol. 43, 223 (1994)

Y. Azizoğlu, M. Gärdsback, B. Sjöberg, L.-E. Lindgren, in Proceedings of the XIII International Conference on Computational Plasticity: Fundamentals and Applications (COMPLAS XIII), ed. by E. Oñate, D.R.J. Owen, D. Peric, M. Chiumenti (International Center for Numerical Methods in Engineering (CIMNE) Barcelona, Spain, 2015), p. 716

Y. Hayakawa, M. Muraki, J.A. Szpunar, Acta Mater. 46, 1063 (1998)

D.A. Molodov, in Recrystallization and Grain Growth, ed. by G. Gottstein, D.A. Molodov. the 1st Joint International Conference on Recrystallization and Grain Growth, Germany, 27-31 August, 2001 (Springer-Verlag, Germany, 2001), p. 21

H. Park, D.N. Lee, Metall. Mater. Trans. A 34, 531 (2003)

H. Park, S.-H. Kim, S.-J. Kim, H.-J. Lee, Korean J. Met. Mater. 56, 861 (2018)

H. Park, S.-H. Kim, W.-J. Lee, J.-W. Ha, S.-J. Kim, H.-J. Lee, Met. Mater. Int. 27, 2220 (2021)

H.-S. Nam, D.N. Lee, J. Electrochem. Soc. 146, 3300 (1999)

A. Fattah-Alhosseini, M. Mosavi, A. Allahdadi, Int. J. Electrochem. 2011, 505929 (2011)

Acknowledgements

This research was supported by the National Research Foundation of Korea (NRF) funded by the Ministry of Education (NRF-2016R1D1A1B02015781).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Park, H., Lee, WJ., Son, JH. et al. Effects of Pilger Rolling and Heat Treatment on Microstructure and Corrosion Resistance of Ag-Electroplated 304 Stainless Steel Tubes. Met. Mater. Int. 28, 1881–1889 (2022). https://doi.org/10.1007/s12540-021-01089-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-021-01089-1