Abstract

This paper introduced a method of rapid solid-phase bonding Al block with Ag as the intermediate layer by longitudinal ultrasonic vibration under eutectic temperature in the atmospheric environment. This method is suitable for the application of structural lightweight design. It was observed that Al and Ag diffuse with each other in the weld seam to form an intermetallic compound Ag2Al with close hexagonal structure. The effects of different reaction temperatures and ultrasonic vibration times on the microstructure and mechanical properties of intermetallic compound Ag2Al were discussed. The influence of the effect of ultrasonic softening waves on surface oxide film rupture and element diffusion was explored. With the increase of ultrasonic vibration time, the intermetallic compounds grew along with the interface and the thickness increased. When the welding temperature was 500 °C and the ultrasonic vibration was 20 s, the highest average strength of the welded joint reaches 46.68 MPa.

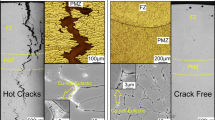

Graphic Abstract

Similar content being viewed by others

Data Availability

All data generated or used during the study appear in the submitted article.

References

P. Chai, Y. Wang, Met. Mater. Int. 25, 1574 (2019)

J.S. Kim, J. Park, K.S. Lee, S. Lee, Y.W. Chang, Met. Mater. Int. 22, 771 (2016)

D.S. Wong, P. Lavoie, JOM 71, 2926 (2019)

W.X. Yang, Y. Yuan, G.Y. Liu, B. Zhang, R.K. Yang, Mater. Lett. 226, 4 (2018)

S.A. Anggraini, M. Uehara, H. Yamada, M. Akiyama, Mater. Lett. 219, 247 (2018)

R.S. Long, E. Boettcher, D. Crawford, JOM 69, 2635 (2017)

H.H. Li, Z.L. Hu, W.Z. Hu, L. Hua, JOM 71, 1687 (2019)

Q. Wang, X.G. Chen, L. Zhu, J.C. Yan, Z.W. Lai, P.Z. Zhao, J.C. Bao, G.C. Lv, C. You, X.Y. Zhou, J. Zhang, Y.T. Li, Ultrason. Sonochem. 34, 947 (2017)

L. Shi, J.C. Yan, B. Peng, Y.F. Han, Mater. Sci. Eng. A 528, 7084 (2011)

Z.W. Xu, J.C. Yan, B.Y. Zhang, X.L. Kong, S.Q. Yang, Mater. Sci. Eng. A 415, 80 (2006)

Z.W. Niu, Z. Ye, J.H. Huang, H. Yang, J. Yang, S.H. Chen, Mater. Charact. 138, 78 (2018)

S.P. Hu, C.N. Niu, H. Bian, X.G. Song, J. Cao, D.Y. Tang, Mater. Lett. 218, 86 (2018)

J.M. Shi, Q. Wang, X.Y. Tian, J.L. Li, L.X. Zhang, J. Manuf. Process. 47, 211 (2019)

M.S. Kenevisi, S.M. Mousavi Khoie, Mater. Lett. 76, 144 (2012)

J. Wang, Y.J. Li, H.J. Ma, Vacuum 79, 45 (2005)

Z.W. Niu, J.H. Huang, K.K. Liu, F.Z. Xu, S.H. Chen, X.K. Zhao, Mater. Lett. 179, 47 (2016)

W.L. Wang, Y.C. Tsai, Mater. Charact. 68, 42 (2012)

M.H. Vini, O.H. Zadeh, Int. J. Mater. Res. 109, 42 (2018)

H.F. Yang, Q. Tan, H.J. Ji, Z.H. Wang, W.F. Xu, M.Y. Li, Mater. Lett. 252, 103 (2019)

C. Xu, Q. Lang, Q. Wang, Y.R. Chen, J.C. Yan, S.Y. Chen, JOM 71, 2025 (2019)

Q. Wang, Y. Fu, Q. Lang, J.C. Yan, S.Y. Chen, Mater. Lett. 237, 37 (2019)

L. Zhu, Q. Wang, L. Shi, X. Zhang, T.H. Yang, J.C. Yan, X.Y. Zhou, Mater. Sci. Eng. A 711, 94 (2018)

S. Roh, C. Lee, Met. Mater. Int. 25, 425 (2019)

K.K. Chen, Y.S. Zhang, H.Z. Wang, Ultrasonics 75, 9 (2017)

J. Hu, T. Shimizu, T. Yoshino, T. Shiratori, M. Yang, Ultrasonics 107, 106107 (2020)

T.R. Bieler, A.K. Mukherjee, Mater. Trans. JIM 128, 171 (1991)

Z.H. Yao, G.Y. Kim, Z.H. Wang, L.A. Faidley, Q.Z. Zou, D.Q. Mei, Z.C. Chen, Int. J. Plast. 39, 75 (2012)

A.V. Kozlov, S.I. Selitser, Mater. Sci. Eng. A 131, 17 (1991)

T.S. Ge, Acta Metall. Sin. 33, 9 (1997)

M. Stiehler, U. Giegengack, J. Barzola-Quiquia, J. Rauchhaupt, S. Schulze, P. Haussler, J. Phys. Chem. Sol. 68, 1244 (2007)

S.W. Fu, C.C. Lee, Mater. Sci. Eng. A 722, 160 (2018)

S.S. Lim, P.L. Rossiter, J.E. Tibballs, Calphad 19, 131 (1995)

Z.Z. Zhang, J.M. Rosalie, N.V. Medhekar, L. Bourgeois, Acta Mater. 174, 116 (2019)

A.A. Ward, Y.B. Zhang, Z.C. Cordero, Acta Mater. 159, 393 (2018)

R.T. Murzaev, D.V. Bachurin, A.A. Nazarov, Phys. Met. Metallogr. 118, 621 (2017)

S. Najafi, A.R. Eivani, M. Samaee, H.R. Jafarian, J. Zhou, Mater. Charact. 136, 60 (2018)

M. Mayer, R. Schwizer, in Proceedings of the 5th Electronics Packaging Technology Conference, EPTC 2003. Singapore, December 10-12, 2003. Thermosonic ball bonding model based on ultrasonic friction power (IEEE, Piscataway, NJ, 2003), pp.738–743

K.K. Chen, Y.S. Zhang, H.Z. Wang, Sci. Technol. Weld. Join. 22, 208 (2017)

I.E. Gunduz, T.C. Ando, E. Shattuck, P.Y. Wong, C.C. Doumanidis, Scripta Mater. 52, 939 (2005)

N. Li, J. Wang, J.Y. Huang, A. Mistra, X. Zhang, Scripta Mater. 63, 363 (2010)

J. Wang, A. Misra, Curr. Opin. Solid State Mater. 15, 20 (2011)

Z.D. Kou, Y.Q. Yang, L.X. Yang, B. Huang, Y.X. Chen, X. Luo, Mater. Sci. Eng. A 729, 125 (2018)

Acknowledgements

This research was sponsored by the National Natural Science Foundation of China (Grant No. 51504165), the Tian** Sci. & Tec. Project (Grant No. 16JCQNJC02600).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No conflict of interest exits in the submission of this manuscript, and manuscript is approved by all authors for publication. I would like to declare on behalf of my co-authors that the work described was original research that has not been published previously, and not under consideration for publication elsewhere, in whole or in part. All the authors listed have approved the manuscript that is enclosed.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ning, B., Nie, Y., Wang, Q. et al. Longitudinal Ultrasonic Vibration Assisted Rapid Solid Phase Bonding of 2024 Aluminum Alloy Using Ag as Interlayer for Structure Lightweight Design. Met. Mater. Int. 27, 2059–2066 (2021). https://doi.org/10.1007/s12540-020-00891-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00891-7