Abstract

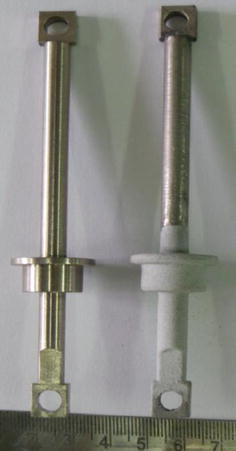

As a catalytic support for passive autocatalytic recombiner in nuclear power plants, anodic alumina layer was formed on stainless steel 304 by applying either Al or NiAl diffusion coatings on 304SS, followed by anodization and calcination. The anodic alumina had porous and nano-fibrous morphology and showed comparable hydrogen conversion ratio as the conventional wash-coated catalytic support. Integrity of catalytic supports was evaluated by steam oxidation test at 900 °C for 100 h. The wash-coated catalytic support exhibited oxide breakaway and Fe-oxide formation. On the other hand, α-alumina was formed on anodized catalytic support with Al or NiAl diffusion layers, which showed good adherence to the underlying metal substrate.

Similar content being viewed by others

References

E.-A. Reinecke, I.M. Tragsdorf, K. Gierling, Studies on innovative hydrogen recombiners as safety devices in the containments of light water reactors. Nucl. Eng. Des. 230(1-3), 49–59 (2004)

E.-A. Reinecke, St. Kelm, D. Heidelberg, M. Klauck, P.-M. Steffen, H.-J. Allelein, Modeling the start-up behavior of passive auto-catalytic recombiners in REKO-DIREKT, in Proceeding of the 8th European Review Meeting on Severe Accident Research, Warsaw, Poland, 16–18 May 2017

S. Gupta, T. Kanzleiter, G. Poss, Passive autocatalytic recombiners (PAR) induced ignition and the resulting hydrogen deflagration behavior in LWR containments, in: Proceeding of the 16th International Topical Meeting on Nuclear Reactor Thermal Hydraulics, Chicago, 30 August–4 September 2015

T.P. Tran, Y. Guo, J. Chen, L. Zhou, M. Sakurai, H. Kameyama, Effect of pore widening treatment on BET surface area of rapidly anodized alumina support. J. Chem. Eng. Jpn. 41, 1042–1048 (2008)

Y. Guo, L. Zhou, H. Kameyama, Thermal and hydrothermal stability of a metal monolithic anodic alumina support for steam reforming of methane. Chem. Eng. J. 168, 341–350 (2011)

Y. Guo, M. Sakurai, H. Kameyama, A. Matsuyama, Y. Kudoh, Preparation of alumite support and preliminary activity investigation for NO removal in SCR-HC over alumite catalyst. J. Chem. Eng. Jpn. 36, 1470–1479 (2003)

D. Kim, D. Kim, H.J. Lee, C. Jang, Corrosion characteristics of Ni-base superalloys in high temperature steam with and without hydrogen. J. Nucl. Mater. 441, 612–622 (2013)

N. Bhuvaneswaran, U.K. Mudali, P. Shankar, Characterization of aluminide coatings formed by diffusion alloying on nitrogen-containing type 316L stainless steels. Scr. Mater. 49, 1133–1138 (2003)

Y. Zhang, A.P. Liu, B.A. Pint, Interdiffusional degradation of oxidation-resistant aluminide coatings on Fe-base alloys. Mater. Corros. 58(10), 751–761 (2007)

V.A. Ravi, T.K. Nguyen, J.C. Nava, Aluminizing of steel to improve high temperature corrosion resistance. Thermochem. Surface Eng. Steels 751–767 (2015)

V. Meille, Review on methods to deposit catalysts on structured surfaces. Appl. Catal. A 315, 1–17 (2006)

L. Zheng, X. Peng, F. Wang, Comparison of the dry and wet oxidation at 900 °C of η-Fe2Al5 and δ-Ni2Al3 coatings. Corros. Sci. 53, 597–603 (2011)

H. Kim, H. Jang, G. Obulan Subramanian, C. Kim, C. Jang, Development of alumina-forming duplex stainless steels as accident-tolerant fuel cladding materials for light water reactors. J. Nucl. Mater. 507, 1–14 (2018)

X. Xu, X. Zhang, G. Chen, Z. Lu, Improvement of high-temperature oxidation resistance and strength in alumina-forming austenitic stainless steels. Mater. Lett. 65, 3285–3288 (2011)

C.E.R. de Carvalho, G.M. de Costa, A.B. Cota, E.H. Rossi, High temperature oxidation behavior of AISI 304 and AISI 430 stainless steels. Mater. Res. 9, 393–397 (2006)

Acknowledgements

This study was supported by the MOTIE/KETEP of the Republic of Korea (No. 20151520101050). Financial support for three of the authors was provided by the BK-Plus Program of the MSIP/NRF of the Republic of Korea.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, C., Kim, S.H., Obulan Subramanian, G. et al. Integrity of Alumina Catalytic Support Prepared by Anodization in a High Temperature Steam Environment. Met. Mater. Int. 25, 324–332 (2019). https://doi.org/10.1007/s12540-018-0198-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-018-0198-0