Abstract

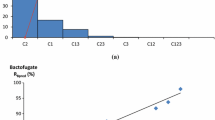

Different studies have demonstrated the effect of organic acids and minerals on the decrease of ethanol production by yeast fermentation. Other impacts have been observed at the operational level, such as increased consumption of inputs, higher occurrence of fouling in equipment, more frequent episodes of microbial contamination or difficulties in handling by-products, among others. Since 2018 these adverse effects have been increasingly observed in Colombia’s sugarcane agro-industrial sector. The sludge present in the raw material (cane molasses) is one of the sources of microbial contamination by lactic acid bacteria, acetic acid bacteria, and wild yeasts. The Providencia Sugar Mill located in rural El Cerrito, Department of Valle del Cauca, Colombia, accordingly implemented in 2011 a sludge removal technology by sedimentation, improving the operating conditions of equipment such as plate heat exchangers, pipes and mash column. However, the increase in concentrations of organic and inorganic impurities in the cane molasses prompted the study of strategies to mitigate these sources of impact on the fermentation process. Laboratory tests indicated that temperature was the variable that had the greatest impact on the removal of insolubles. Under the most optimal conditions possible, the decrease in insolubles was 74%, with decreases of 15% in ashes, 27.4% in calcium, 15.4% in magnesium and 4.8% in potassium as well. Laboratory results were then validated on an industrial scale, indicating that a 86% decrease in turbidity was obtained with operating temperatures ≥ 75 °C.

Similar content being viewed by others

References

Costa, Assis, Ohana Yonara, Betulia Morais Souto, Daiva Domenach Tupinambá, Jessica Carvalho Bergmann, Cynthia Maria Kyaw, Ricardo Henrique Kruger, Cristine Chaves Barreto, and Betania Ferraz Quirino. 2015. Microbial diversity in sugarcane ethanol production in a Brazilian distillery using a culture-independent method. Journal of Industrial Microbiology and Biotechnology 42: 73–84. https://doi.org/10.1007/s10295-014-1533-1.

Awad-allah, M., A. Abdelrahman, and U. Mostafa. 2006. Exhaustibility of molasses from different sources 1-Solubility of sucrose. In Proceedings of the 3rd Egyptian & Syrian Conference of Agriculture and Food in the Arab World.

Cenicaña. 2020. Informe Anual 2020 - Centro de Investigación de la Caña de Azúcar de Colombia. CENICAÑA. Cali.

Dani, R. V., S. Panda, and N. Gopalakrishnan. 2023. Clarification of B heavy molasses for better kee** quality and to minimize distillery scaling problems. In: Proceedings of the XXXI Congress of the International Society of Sugar Cane Technologists, Hyderabad, India, 31: 967–976. Reduit, Mauritius: ISSCT.

Daza-Merchan, Zully Tatiana, Gloria Prieto Correal, David Palacios Garcia, and Nicolás Javier Gil. 2019. Microbial action in cane processing goes beyond sucrose loss. In: Proceedings of the XXX Congress of the International Society of Sugar Cane Technologists, Tucumán, Argentina, 257–269. Reduit, Mauritius: ISSCT.

Herrera, E. 2013. Evaluación técnica de la operación de clarificación de meladura en el proceso de producción de azúcar. Cali, Colombia: Universidad del Valle.

ICUMSA (International Commission for Uniform Methods of Sugar Analysis). 1994. ICUMSA Method GS1/3/4/7/8–13. England: ICUMSA.

ICUMSA (International Commission for Uniform Methods of Sugar Analysis). 2013. ICUMSA Method GS7–31. England: ICUMSA.

Lucena, B.T.L., and M.A. de Morais Júnior. 2010. Diversidade genética de bactérias lácticas presentes em destilarias de álcool combustível nos Estados da Paraíba e Pernambuco. Tese de Doutorado. Recife: Universidade Federal de Pernambuco-Programa de Pós-Graduação em Genética.

Moro P., J. 2012. Diseño y construcción de un clarificador de melaza para mejorar los procesos de fermentación alcohólica. Universidad Nacional Agraria de la Selva. Facultad de Industrias Alimentarias. http://repositorio.unas.edu.pe/handle/UNAS/263?show=full

Parra, J., D. Parrado, M. Martinez, M. Tello, A. Moreno, and I. Rivera. 2011. Acondicionamiento de la materia prima utilizada en la producción de etanol anhidro en El Ingenio Providencia. Revista Tecnicaña 27: 11–19.

Peacock, Steve. 1995. Predicting physical properties of factory juices and syrups. International Sugar Journal 97 (1162): 571–577.

Industries, Praj. 2004. Analytical methods for cane feedstock-based fermentation and distillation process, 4th ed. Pune, India: Praj Matrix-The Innovation Center.

Raharja, R., U. Murdiyatmo, A. Sutrisno, and A.K. Wardani. 2019. Bioethanol production from sugarcane molasses by instant dry yeast. In IOP Conference Series: Earth and Environmental Science 230: 012076. England: IOP Publishing.

Rein, Peter. 2007. Cane Sugar Engineering. Lst. Berlin: Verlag Dr. Albert Bartens KG.

Acknowledgements

Our sincere appreciation to our colleagues María Camila Espinosa, Felipe Lozano, Esteban Benavides and Sebastián Soto for their valuable input to this study, to the Providencia Sugar Mill for allowing us to carry out this research at its facilities, and to the sugar and alcohol production plants of Colombia’s sugarcane agro-industrial sector.

Funding

There was no external funding for the study.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design, material preparation, data collection and analysis.

Corresponding author

Ethics declarations

The authors declare no conflict of interest. It also complies with all the ethical requirements of the journal. Please do not hesitate to contact us for any questions. On the other hand, no tests on humans or animals were performed in the research.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yépez-Vela, D.F., Sierra-Becerra, J., Balcázar-Valencia, J.D. et al. Removing Sludge from B Molasses at the Providencia Sugar Mill Distillery: Performance Evaluation and Proposed Operating Alternative. Sugar Tech 26, 902–907 (2024). https://doi.org/10.1007/s12355-024-01404-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12355-024-01404-1