Abstract

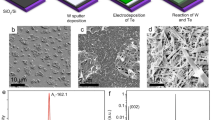

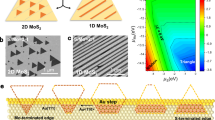

Group-VI elemental two-dimensional (2D) materials (e.g., tellurene (Te)) have unique crystalline structures and extraordinarily physical properties. However, it still remains a great challenge to controllably grow 2D Te with good repeatability, uniformity, and highly aligned orientation using vapor growth method. Here, we design a Cu foil-assisted alloy-buffer-controlled growth method to epitaxially grow aligned single-crystalline 2D Te on an insulating mica substrate. The in-situ formation of Cu−Te alloy plays a key role on 2D Te growth, alleviating the spatial and temporal non-uniformity of precursor in conventional vapor deposition process. Through transmission electron microscopy (TEM) analysis combined with theoretical calculations, we unveil that the alignment growth of Te in the [110] direction is along the [600] direction of mica, owing to the small lattice mismatch (0.15%) and strong binding strength. This work presents a method to grow aligned high-quality 2D Te in a controllable manner.

Similar content being viewed by others

References

Lin, Z. Y.; Huang, Y.; Duan, X. F. Van der Waals thin-film electronics. Nat. Electron. 2019, 2, 378–388.

Liu, C.; Wang, L.; Qi, J. J.; Liu, K. H. Designed growth of large-size 2D single crystals. Adv. Mater. 2020, 32, 2000046.

Mounet, N.; Gibertini, M.; Schwaller, P.; Campi, D.; Merkys, A.; Marrazzo, A.; Sohier, T.; Castelli, I. E.; Cepellotti, A.; Pizzi, G. et al. Two-dimensional materials from high-throughput computational exfoliation of experimentally known compounds. Nat. Nanotechnol. 2018, 13, 246–252.

Zhang, Y.; Yao, Y. Y.; Sendeku, M. G.; Yin, L.; Zhan, X. Y.; Wang, F.; Wang, Z. X.; He, J. Recent progress in CVD growth of 2D transition metal dichalcogenides and related heterostructures. Adv. Mater. 2019, 31, 1901694.

Yang, Y.; Zhang, K. X.; Zhang, L. B.; Hong, G.; Chen, C.; **g, H. M.; Lu, J. B.; Wang, P.; Chen X. S.; Wang, L. et al. Controllable growth of type-II Dirac semimetal PtTe2 atomic layer on Au substrate for sensitive room temperature terahertz photodetection. InforMat 2021, 3, 705–715.

Huang, L.; Hu, Z. M.; **, H. R.; Wu, J. B.; Liu, K. S.; Xu, Z. H.; Wan, J.; Zhou, H.; Duan, J. J.; Hu, B. et al. Salt-assisted synthesis of 2D materials. Adv. Funct. Mater. 2020, 30, 1908486.

**g, X.; Illarionov, Y.; Yalon, E.; Zhou, P.; Grasser, T.; Shi, Y. Y.; Lanza, M. Engineering field effect transistors with 2D semiconducting channels: Status and prospects. Adv. Funct. Mater. 2020, 30, 1901971.

Miró, P.; Audiffred, M.; Heine, T. An atlas of two-dimensional materials. Chem. Soc. Rev. 2014, 43, 6537–6554.

Li, X. B.; Chen, C.; Yang, Y.; Lei, Z. B.; Xu, H. 2D Re-based transition metal chalcogenides: Progress, challenges, and opportunities. Adv. Sci. 2020, 7, 2002320.

Lin, Z. Y.; Wang, C.; Chai, Y. Emerging group-VI elemental 2D materials: Preparations, properties, and device applications. Small 2020, 16, 2003319.

Qin, J. K.; Liao, P. Y.; Si, M. W.; Gao, S. Y.; Qiu, G.; Jian, J.; Wang, Q. X.; Zhang, S. Q.; Huang, S. Y.; Charnas, A. et al. Raman response and transport properties of tellurium atomic chains encapsulated in nanotubes. Nat. Electron. 2020, 3, 141–147.

Wang, Y. X.; Qiu, G.; Wang, R. X.; Huang, S. Y.; Wang, Q. X.; Liu, Y. Y.; Du, Y. C.; Goddard III, W. A.; Kim, M. J.; Xu, X. F. et al. Field-effect transistors made from solution-grown two-dimensional tellurene. Nat. Electron. 2018, 1, 228–236.

Zhao, C. S.; Tan, C. L.; Lien, D. H.; Song, X. H.; Amani, M.; Hettick, M.; Nyein, H. Y. Y.; Yuan, Z.; Li, L.; Scott, M. C. et al. Evaporated tellurium thin films for p-type field-effect transistors and circuits. Nat. Nanotechnol. 2020, 15, 53–58.

Qin, J. K.; Qiu, G.; Jian, J.; Zhou, H.; Yang, L. M.; Charnas, A.; Zemlyanov, D. Y.; Xu, C. Y.; Xu, X. F.; Wu, W. Z. et al. Controlled growth of a large-size 2D Selenium nanosheet and its electronic and optoelectronic applications. ACS Nano 2017, 11, 10222–10229.

Qin, J. K.; Qiu, G.; He, W.; Jian, J.; Si, M. W.; Duan, Y. Q.; Charnas, A.; Zemlyanov, D. Y.; Wang, H. Y.; Shao, W. Z. et al. Epitaxial growth of 1D Atomic chain based Se nanoplates on monolayer ReS2 for high-performance photodetectors. Adv. Funct. Mater. 2018, 28, 1806254.

**ng, C. Y.; **e, Z. J.; Liang, Z. M.; Liang, W. Y.; Fan, T. J.; Ponraj, J. S.; Dhanabalan, S. C.; Fan, D. Y.; Zhang, H. 2D nonlayered selenium nanosheets: Facile synthesis, photoluminescence, and ultrafast photonics. Adv. Opt. Mater. 2017, 5, 1700884.

Qin, J. K.; Zhou, F. C.; Wang, J. L.; Chen, J. W.; Wang, C.; Guo, X. Y.; Zhao, S. X.; Pei, Y.; Zhen, L.; Ye, P. D. et al. Anisotropic signal processing with trigonal selenium nanosheet synaptic transistors. ACS Nano 2020, 14, 10018–10026.

Qin, J. K.; Wang, C.; Zhen, L.; Li, L. J.; Xu, C. Y.; Chai, Y. Van der Waals heterostructures with one-dimensional atomic crystals. Prog. Mater. Sci. 2021, 122, 100856.

Qiao, J. S.; Pan, Y. H.; Yang, F.; Wang, C.; Chai, Y.; Ji, W. Few-layer Tellurium: One-dimensional-like layered elementary semiconductor with striking physical properties. Sci. Bull. 2018, 63, 159–168.

Du, Y. C.; Qiu, G.; Wang, Y. X.; Si, M. W.; Xu, X. F.; Wu, W. Z.; Ye, P. D. One-dimensional van der Waals material tellurium: Raman spectroscopy under strain and magneto-transport. Nano Lett. 2017, 17, 3965–3973.

Zhao, C. S.; Batiz, H.; Yasar, B.; Kim, H.; Ji, W. B.; Scott, M. C.; Chrzan, D. C.; Javey, A. Tellurium single-crystal arrays by low-temperature evaporation and crystallization. Adv. Mater. 2021, 33, 2100860.

Chen, J. Y.; Zhao, X. X.; Tan, S. J. R.; Xu, H.; Wu, B.; Liu, B.; Fu, D. Y.; Fu, W.; Geng, D. H.; Liu, Y. P. et al. Chemical vapor deposition of large-size monolayer MoSe2 crystals on molten glass. J. Am. Chem. Soc. 2017, 139, 1073–1076.

Liu, L. N.; Wu, J. X.; Wu, L. Y.; Ye, M.; Liu, X. Z.; Wang, Q.; Hou, S. Y.; Lu, P. F.; Sun, L. F.; Zheng, J. Y. et al. Phase-selective synthesis of 1T’ MoS2 monolayers and heterophase bilayers. Nat. Mater. 2018, 17, 1108–1114.

Lin, Z. Y.; Zhao, Y. D.; Zhou, C. J.; Zhong, R.; Wang, X. S.; Tsang, Y. H.; Chai, Y. Controllable growth of large-size crystalline MoS2 and resist-free transfer assisted with a Cu thin film. Sci. Rep. 2016, 5, 18596.

Lim, H. E.; Irisawa, T.; Okada, N.; Okada, M.; Endo, T.; Nakanishi, Y.; Maniwa, Y.; Miyata, Y. Monolayer MoS2 growth at the Au−SiO2 interface. Nanoscale 2019, 11, 19700–19704.

Yang, P. F.; Zhang, S. Q.; Pan, S. Y.; Tang, B.; Liang, Y.; Zhao, X. X.; Zhang, Z. P.; Shi, J. P.; Huan, Y. H.; Shi, Y. P. et al. Epitaxial growth of centimeter-scale single-crystal MoS2 monolayer on Au (111). ACS Nano 2020, 14, 5036–5045.

Momeni, K.; Ji, Y. Z.; Zhang, K. H.; Robinson, J. A.; Chen, L. Q. Multiscale framework for simulation-guided growth of 2D materials. npj 2D Mater. Appl. 2018, 2, 27.

Zhou, X. S.; Wu, Y. Y.; Yang, X. G.; Huang, C. W. Numerical analysis of an inline metal-organic chemical vapour deposition process based on sliding-mesh modelling. Coatings 2020, 10, 1198.

Zhang, F.; Momeni, K.; AlSaud, M. A.; Azizi, A.; Hainey, M. F.; Redwing, J. M.; Chen, L. Q.; Alem, N. Controlled synthesis of 2D transition metal dichalcogenides: From vertical to planar MoS2. 2D Mater. 2017, 4, 025029.

Abbas, H. G.; Hahn, J. R. Crystallization mechanism of liquid tellurium from classical molecular dynamics simulation. Mater. Chem. Phys. 2020, 240, 122235.

Chandrasekaran, S.; Basak, T.; Ramanathan, S. Experimental and theoretical investigation on microwave melting of metals. J. Mater. Process. Technol. 2011, 211, 482–487.

Zhang, X.; Jiang, J. Z.; Suleiman, A. A.; **, B.; Hu, X. Z.; Zhou, X.; Zhai, T. Y. Hydrogen-assisted growth of ultrathin Te flakes with giant gate-dependent photoresponse. Adv. Funct. Mater. 2019, 29, 1906585.

Pashinkin, A. S.; Fedorov, V. A. Phase equilibria in the Cu−Te system. Inorg. Mater. 2003, 39, 539–554.

Perdew, J. P.; Burke, K.; Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 1996, 77, 3865–3868.

Ghoshal, D.; Shang, H. Z.; Sun, X.; Wen, X. X.; Chen, D. X.; Wang, T. M.; Lu, Z. H.; Gupta, T.; Efstathiadis, H.; West, D. et al. Orientation-controlled large-area epitaxial PbI2 thin films with tunable optical properties. ACS Appl. Mater. Interfaces 2021, 13, 32450–32460.

Acknowledgements

This work was supported by the Research Grant Council of Hong Kong (No. PolyU 152053/18E) and the Shenzhen Science and Technology Innovation Commission (No. JCYJ20180507183424383).

Author information

Authors and Affiliations

Corresponding author

Electronic Supplementary Material

Rights and permissions

About this article

Cite this article

Wang, C., Xu, C., Guo, X. et al. Alloy-buffer-controlled van der Waals epitaxial growth of aligned tellurene. Nano Res. 15, 5712–5718 (2022). https://doi.org/10.1007/s12274-022-4188-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12274-022-4188-7