Abstract

Introduction

In this article, we demonstrate the application of cooling crystallization to generate novel solid forms of drug-coformer cocrystal complexes.

Method

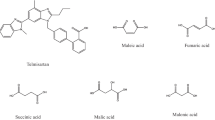

This approach enabled us to replicate several cocrystal phases previously reported for pharmaceutical drugs. Additionally, we successfully produced a new solid mixture comprising the drug luliconazole and coformers such as mannitol and menthol, as well as a potential new crystal form of the cocrystal luliconazole:menthol and luliconazole:mannitol. By utilizing cooling crystallization, we were able to prepare phase-pure LCZ-MNT and LCZ-MNL cocrystals.

Result

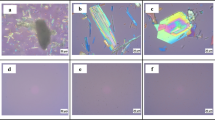

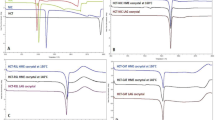

This study utilized PXRD, thermal methods, and FTIR to analyze cocrystals formed between drug and two coformers, menthol (MNT) and mannitol (MNL). Pure luliconazole showed−345.26 mJ heat of fusion (ΔH) and cocrystals with menthol and mannitol showed−516.19 mJ and−566.46 mJ respectively. The cocrystals showed lower heats of fusion (ΔH) compared to luliconazole, indicating the possibility of increased entropy and solubility for all cocrystals. Both the coformer and drug components showed band shifts in their spectra. A new solid phase was assumed to have formed if the PXRD of the cocrystal product differed from that of the reactants. Pure luliconazole resulted in 6.91 µg/ml solubility and cocrystal with menthol resulted in 26.87 µg/ml solubility. Using cooling crystallization with the menthol coformer resulted in a fivefold increase in cocrystal solubility compared to pure drug. The study also demonstrated improvements in drug dissolution.

Conclusion

The DSC analysis showed that the cooling crystallization method resulted in cocrystals with lower heats of fusion. The results of FTIR studies, the drug, and coformer showed only weak interactions, creating the new solid form. PXRD data indicated that the cooling crystallization method modified the crystal habits. Solubility and dissolution studies revealed that cocrystals of luliconazole could be an effective approach for enhancing its solubility.

Graphical Abstract

Similar content being viewed by others

Data Availability

The represented data is authentic, objective, and a true depiction of the research study.

References

Scher RK, Nakamura N, Tavakkol A. Luliconazole: a review of a new antifungal agent for the topical treatment of onychomycosis. Mycoses. 2014;57(7):389–93.

Sharma M, Mundlia J, Kumar T, Ahuja M. A novel microwave-assisted synthesis, characterization and evaluation of luliconazole-loaded solid lipid nanoparticles. Polym Bull. 2021;78(5):2553–67.

Hasan S, Bhandari S, Sharma A. International journal of research publication and reviews formulation and evaluation of luliconazole emulgel [Internet]. Vol. 3, International journal of research publication and reviews. 2022. Available from: http://www.ijrpr.com

Shaikh MS, Kale MA, Shaikh MM, Mahaparale PR. Formulation, characterization and antimicrobial studies of lyophilized luliconazole nanosuspension for enhancing solubility using modified polymer. Int J Polym Mater Polym Biomater. 2022;71(9):692–706.

Saunders J, Maki K, Koski R, Nybo SE. Tavaborole, Efinaconazole, and luliconazole: three new antimycotic agents for the treatment of dermatophytic fungi. J Pharm Prac. SAGE Publications Inc. 2017;30:621–30.

Sathisaran I, Dalvi SV. Engineering cocrystals of poorlywater-soluble drugs to enhance dissolution in aqueous medium. Pharmaceutics. MDPI AG. 2018;10.

Vimalson DC, Parimalakrishnan S, Jeganathan NS, Anbazhagan S. Techniques to enhance solubility of hydrophobic drugs: an overview. Asian J Pharm. 10.

Savjani KT, Gajjar AK, Savjani JK. Drug solubility: importance and enhancement techniques. ISRN Pharm. 2012;5(2012):1–10.

Siepmann J, Siepmann F. Mathematical modeling of drug dissolution. Int J Pharm. Elsevier B.V. 2013;453:12–24.

Patel DJ, Puranik PK. Pharmaceutical co-crystal : an emerging technique to enhance physicochemical properties of drugs. Int J Chemtech Res. 2020;13(3):283–90.

Duggirala NK, Frericks Schmidt HL, Lei Z, Zaworotko MJ, Krzyzaniak JF, Arora KK. Solid-state characterization and relative formation enthalpies to evaluate stability of cocrystals of an antidiabetic drug. Mol Pharm. 2018;15(5):1901–8.

Kumar A, Nanda A. In-silico methods of cocrystal screening: a review on tools for rational design of pharmaceutical cocrystals. Vol. 63, Journal of drug delivery science and technology. Editions de Sante; 2021.

Mohite R, Mehta P, Arulmozhi S, Kamble R, Pawar A, Bothiraja C. Synthesis of fisetin co-crystals with caffeine and nicotinamide using the cooling crystallization technique: biopharmaceutical studies. New J Chem. 2019;43(34):13471–9.

Desai H, Rao L, Amin P. Carbamazepine cocrystals by solvent evaporation technique: formulation and characterisation studies ocular drug delivery for the treatment of glaucoma view project cocrystallization of poorly soluble drugs view project [Internet]. 2014. Available from: http://www.ajptr.com

Karimi-Jafari M, Padrela L, Walker GM, Croker DM. Creating cocrystals: a review of pharmaceutical cocrystal preparation routes and applications. Cryst Growth Des. Am Chem Soc 2018;18:6370–87.

Izutsu KI, Koide T, Takata N, Ikeda Y, Ono M, Inoue M, et al. Characterization and quality control of pharmaceutical cocrystals. Chem Pharm Bull. 64:1421.

Bhanu P, Sundararajan R. Spectrophotometric determination of luliconazole in bulk and pharmaceutical dosage form. Res J Pharm Technol. 2020;13(2):928–32.

Losev E, Boldyreva E. The effect of amino acid backbone length on molecular packing: Crystalline tartrates of glycine, β-alanine, γ-aminobutyric acid (GABA) and dl-α-aminobutyric acid (AABA). Acta Crystallogr C Struct Chem. 2018;74(2):177–85.

Suhail M, Wu PC, Minhas MU. Development and characterization of pH-sensitive chondroitin sulfate-co-poly(acrylic acid) hydrogels for controlled release of diclofenac sodium. J Saudi Chem Soc. 2021;25(4).

Pralhad T, Rajendrakumar K. Study of freeze-dried quercetin-cyclodextrin binary systems by DSC, FT-IR, X-ray diffraction and SEM analysis. J Pharm Biomed Anal. 2004;34(2):333–9.

Arunkumar N, Deecaraman M, Rani C, Mohanraj KP, Venkates Kumar K. Preparation and solid state characterization of atorvastatin nanosuspensions for enhanced solubility and dissolution. Int J Pharmtech Res. CODEN. Vol. 1.

Weng J, Wong SN, Xu X, Xuan B, Wang C, Chen R, et al. Cocrystal Engineering of itraconazole with suberic acid via rotary evaporation and spray drying. Cryst Growth Des. 2019;19(5):2736–45.

Kumar M, Shanthi N, Kumar Mahato A. Qualitative and quantitative methods for determination of drug luliconazole. International journal of research in advent technology [Internet]. 2018;6(10). Available from: http://www.ijrat.org

Schultheiss N, Newman A. Pharmaceutical cocrystals and their physicochemical properties. Cryst Growth Des. 2009;9:2950–67.

Sugandha K, Kaity S, Mukherjee S, Isaac J, Ghosh A. Solubility enhancement of ezetimibe by a cocrystal engineering technique. Cryst Growth Des. 2014;14(9):4475–86.

Chatur VM, Dhole SN. Development and characterization of niosomal gel for topical delivery of luliconazole. International journal of pharmaceutical research and allied sciences. 2022;11(1):99–107.

Al-Akayleh F, Mohammed Ali HH, Ghareeb MM, Al-Remawi M. Therapeutic deep eutectic system of capric acid and menthol: Characterization and pharmaceutical application. J Drug Deliv Sci Technol. 2019;1:53.

Guimarães TF, Lanchote AD, Da Costa JS, Viçosa AL, De Freitas LAP. A multivariate approach applied to quality on particle engineering of spray-dried mannitol. Adv Powder Technol. 2015;26(4):1094–101.

Kumar M, Shanthi N, Mahato AK, Soni S, Rajnikanth PS. Preparation of luliconazole nanocrystals loaded hydrogel for improvement of dissolution and antifungal activity. Heliyon. 2019;5(5): e01688.

Acknowledgements

I owe my humble thanks to Bioderma Laboratoire for providing gift sample of luliconazole. I owe my deepest gratitude to Mr. Krupal Shanishchara for continuous support and guidance towards this research project.

Funding

The Department of Technical Education, Government of Gujarat, India, provided the financial assistance (minor research grant) provided under the SSIP (Student Startup & Innovation Policy) scheme and KS Patel Centre for Entrepreneurship, RK University for this project.

Author information

Authors and Affiliations

Contributions

All the authors have contributed to the research work and preparation of the final manuscript.

Corresponding author

Ethics declarations

Ethics Approval

No animal or human subjects were used during the preparation of this manuscript.

Consent for Publication

Nil.

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Aghara, M., Dudhat, K. Solubility and Dissolution Enhancement of Luliconazole by a Cocrystal Engineering Technique with Different Coformers. J Pharm Innov 18, 1701–1712 (2023). https://doi.org/10.1007/s12247-023-09751-4

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12247-023-09751-4