Abstract

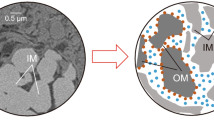

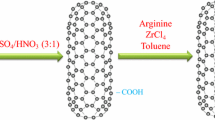

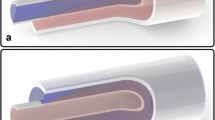

A pore-array intensified tube-in-tube microchannel (PA-TMC), which is characterized by high throughput and low pressure drop, was developed as a gas–liquid contactor. The sulfite oxidation method was used to determine the oxygen efficiency (φ) and volumetric mass transfer coefficient (kLa) of PA-TMC, and the mass transfer amount per unit energy (ε) was calculated by using the pressure drop. The effects of structural and operating parameters were investigated systematically, and the two-phase flow behavior was monitored by using a charge-coupled device imaging system. The results indicated that the gas absorption efficiency and mass transfer performance of the PA-TMC were improved with increasing pore number, flow rate, and number of helical coil turns and decreasing pore size, row number, annular size, annular length, and surface tension. The φ, ε and kLa of PA-TMC could reach 31.3%, 1.73 × 10−4 mol/J, and 7.0 s−1, respectively. The Sherwood number was correlated with the investigated parameters to guide the design of PA-TMC in gas absorption and mass transfer processes.

Similar content being viewed by others

Abbreviations

- \(a\) :

-

Interfacial area, m2/m3

- \(A_{1}\) :

-

Cross-sectional area of annular channel, m2

- \(A_{2}\) :

-

Total area of pore array, m2

- \(c_{1}\) :

-

Oxygen volume fraction of gas phase at reactor inlet, %

- \(c_{2}\) :

-

Oxygen volume fraction of gas phase at reactor outlet, %

- \(c_{{{\text{O}}_{ 2} }}^{*}\) :

-

Concentration of oxygen at the interfacial in the solution, kmol/m3

- \(c_{{{\text{O}}_{ 2} , 0}}^{*}\) :

-

Concentration of oxygen at the interfacial in the water, kmol/m3

- \(C_{{{\text{O}}_{ 2} , {\text{in}}}}\) :

-

Concentration of oxygen in the gas at the inlet, kmol/m3

- \(C_{{{\text{O}}_{ 2} , {\text{out}}}}\) :

-

Concentration of oxygen in the gas at the outlet, kmol/m3

- \(c_{n,j}\) :

-

Mass concentration of organic substances, kg/m3

- \(c_{i}\) :

-

Molar concentration of the i ion, kmol/m3

- \(C_{i}\) :

-

Concentration of the i electrolyte, kmol/m3

- \(d\) :

-

Pore size, m

- \(d_{\text{a}}\) :

-

Annular size, m

- \(D\) :

-

Hydrodynamic diameter of the annular channel, m

- \(D_{0}\) :

-

The molecular diffusivity of oxygen in water, m2/s

- \(D_{\text{out}}\) :

-

Inner diameter of the outer tube, m

- \(D_{{{\text{O}}_{ 2} }}\) :

-

The diffusivity of oxygen in the electrolyte solution, m2/s

- \(D_{\text{in}}\) :

-

Outer diameter of the inner tube, m

- \(h_{\text{i}}\) :

-

Ion-specific parameters

- \(h_{\text{G}}\) :

-

Gas-specific parameters

- \(K_{2}\) :

-

Second-order rate constant, m3/(kmol/s)

- \(k_{\text{L}}\) :

-

Liquid-side mass transfer coefficient, m/s

- \(k_{\text{L}} a\) :

-

Volumetric mass transfer coefficient, s−1

- \(K_{n,j}\) :

-

Sechenov constant of organic substances

- \(L^{ * }\) :

-

Annular length, m

- \(m\) :

-

Helical coil turns

- \(M_{1}\) :

-

Helical coil turns per unit length

- \(n\) :

-

Pore number

- \(N\) :

-

Row number

- \(N_{{{\text{O}}_{ 2} }} a\) :

-

Absorption rate, kmol/(m3/s)

- \(N_{\text{t}}\) :

-

Mass transfer amount per unit time, mol/s

- \(P_{\text{g}}\) :

-

Pressure drop of the gas phase, Pa

- \(P_{\text{L}}\) :

-

Pressure drop of the liquid phase, Pa

- \(P_{\text{t}}\) :

-

Power consumption, W

- \(Q_{\text{in}}\) :

-

Gas flow rate at the inlet, m3/s

- \(Q_{\text{out}}\) :

-

Gas flow rate at the outlet, m3/s

- \(Q_{\text{g}}\) :

-

Gas flow rate, m3/s

- \(Q_{\text{L}}\) :

-

Liquid flow rate, m3/s

- \(T\) :

-

Temperature, K

- \(u_{\text{L}}\) :

-

Liquid-phase velocity in the annular channel, m/s

- \(u_{\text{g}}\) :

-

Gas-phase velocity in the pore array, m/s

- \(V_{\text{r}}\) :

-

Volume of the reactor, m3

- Re:

-

Reynolds number

- Sh:

-

Sherwood number

- φ :

-

Oxygen efficiency

- \(\varepsilon\) :

-

Mass transfer amount per unit energy, mol/J

- \(\mu\) :

-

Liquid-phase viscosity, Pa s

- \(\rho_{\text{g}}\) :

-

Density of gas phase, kg/m3

- \(\rho_{\text{L}}\) :

-

Density of liquid phase, kg/m3

- \(\sigma\) :

-

Surface tension of liquid phase, N/m

References

Straathof NJW, Su YH, Hessel V et al (2016) Accelerated gas-liquid visible light photoredox catalysis with continuous-flow photochemical microreactors. Nat Protoc 11(1):10–21

Nieves-Remacha MJ, Kulkarni AA, Jensen KF (2013) Gas–liquid flow and mass transfer in an advanced-flow reactor. IndEngChem Res 52(26):8996–9010

Mueller SG, Dudukovic MP (2010) Gas holdup in gas–liquid stirred tanks. IndEngChem Res 49(21):10744–10750

Bao YY, Gao ZM, Huang XH et al (2007) Gas–liquid dispersion with buoyant particles in a hot-sparged stirred tank. IndEngChem Res 46(20):6605–6611

Lau R, Peng W, Velazquez-Vargas LG et al (2004) Gas–liquid mass transfer in high-pressure bubble columns. IndEngChem Res 43(5):1302–1311

Gao HX, Xu B, Han L et al (2017) Mass transfer performance and correlations for CO2 absorption into aqueous blended of DEEA/MEA in a random packed column. AIChE J 63(7):3048–3057

Hanley B, Chen CC (2012) New mass-transfer correlations for packed towers. AIChE J 58(1):132–152

Piché S, Grandjean BPA, Larachi F (2002) Reconciliation procedure for gas–liquid interfacial area and mass-transfer coefficient in randomly packed towers. IndEngChem Res 41(19):4911–4920

Kuntz J, Aroonwilas A (2009) Mass-transfer efficiency of a spray column for CO2 capture by MEA. Energy Procedia 1(1):205–209

Gao YX, Hong D, Lu HR et al (2018) Gas holdup and liquid velocity distributions in the up flow jet-loop reactor. ChemEng Res Des 136:94–104

Dehkordi AM, Savari C (2011) Determination of interfacial area and overall volumetric mass-transfer coefficient in a novel type of two im**ing streams reactor by chemical method. IndEngChem Res 50(10):6426–6435

Wang ZH, Yang T, Liu ZX et al (2019) Mass transfer in a rotating packed bed: a critical review. ChemEng Process Process Intensif 139:78–94

Meeuwse M, van der Schaaf J, Kuster BFM et al (2010) Gas–liquid mass transfer in a rotor–stator spinning disc reactor. ChemEngSci 65(1):466–471

Shi JT, Xu SQ, Qin HY et al (2014) Gas–liquid mass transfer characteristics in two inline high shear mixers. IndEngChem Res 53(12):4894–4901

Ganapathy H, Shooshtari A, Dessiatoun S et al (2015) Hydrodynamics and mass transfer performance of a microreactor for enhanced gas separation processes. ChemEng J 266:258–270

Xun T, Cai WF, Zhang XB (2017) The flow pattern and mass transfer of gas-liquid-liquid three phase flow in microchannel. Chem Ind Eng 034(006):81–87 (in Chinese)

Ganapathy H, Steinmayer S, Shooshtari A et al (2016) Process intensification characteristics of a microreactor absorber for enhanced CO2 capture. Appl Energy 162:416–427

Sobieszuk P, Pohorecki R, Cygański P et al (2011) Determination of the interfacial area and mass transfer coefficients in the Taylor gas–liquid flow in a microchannel. ChemEngSci 66(23):6048–6056

Sattari-Najafabadi M, Nasr Esfahany M, Wu Z et al (2018) Mass transfer between phases in microchannels: a review. ChemEng Process Process Intensif 127:213–237

Kashid MN, Renken A, Kiwi-Minsker L (2011) Gas–liquid and liquid–liquid mass transfer in microstructured reactors. ChemEngSci 66(17):3876–3897

Tan J, Du L, Lu YC et al (2011) Development of a gas-liquid microstructured system for oxidation of hydrogenated 2-ethyltetrahydroanthraquinone. ChemEng J 171(3):1406–1414

Fukuyama T, Tokizane M, Matsui A et al (2016) A greener process for flow C-H chlorination of cyclic alkanes using in situ generation and on-site consumption of chlorine gas. React ChemEng 1(6):613–615

de Mas N, Günther A, Schmidt MA et al (2009) Increasing productivity of microreactors for fast gas–liquid reactions: the case of direct fluorination of toluene. IndEngChem Res 48(3):1428–1434

Vanoye L, Wang JD, Pablos M et al (2016) Continuous, fast, and safe aerobic oxidation of 2-ethylhexanal: pushing the limits of the simple tube reactor for a gas/liquid reaction. Org Process Res Dev 20(1):90–94

Peela NR, Lee IC, Vlachos DG (2012) Design and fabrication of a high-throughput microreactor and its evaluation for highly exothermic reactions. IndEngChem Res 51(50):16270–16277

Tan J, Zhang JS, Lu YC et al (2012) Process intensification of catalytic hydrogenation of ethylanthraquinone with gas-liquid microdispersion. AIChE J 58(5):1326–1335

Suryawanshi PL, Gumfekar SP, Bhanvase BA et al (2018) A review on microreactors: reactor fabrication, design, and cutting-edge applications. ChemEngSci 189:431–448

Chen JF, Chen GZ, Wang JX et al (2011) High-throughput microporous tube-in-tube microreactor as novel gas-liquid contactor: mass transfer study. AIChE J 57(1):239–249

Zhang JS, Wang K, Teixeira AR et al (2017) Design and scaling up of microchemical systems: a review. Annu Rev ChemBiomolEng 8(1):285–305

Garciadiego Ortega E, Tsaoulidis D, Angeli P (2018) Predictive model for the scale-out of small channel two-phase flow contactors. ChemEng J 351:589–602

Wang QA, Wang JX, Yu W et al (2009) Investigation of micromixing efficiency in a novel high-throughput microporous tube-in-tube microchannel reactor. IndEngChem Res 48(10):5004–5009

Gao NN, Wang JX, Shao L et al (2011) Removal of carbon dioxide by absorption in microporous tube-in-tube microchannel reactor. IndEngChem Res 50(10):6369–6374

Pan MY, Li T, Zhou Y et al (2015) Selective absorption of H2S from a gas mixture with CO2 in a microporous tube-in-tube microchannel reactor. ChemEng Process: Process Intensif 95:135–142

Sun BC, Li PF, Liang Y et al (2014) Oxidation of ammonium sulfite by oxygen in a microporous tube-in-tube microchannel reactor. ChemEng J 253:258–263

Sun BC, Gao MP, Arowo M et al (2014) Ozonation of acid red 14 in the presence of inorganic salts in a microporous tube-in-tube microchannel reactor. IndEngChem Res 53(49):19071–19076

Gao MP, Zeng ZQ, Sun BC et al (2012) Ozonation of azo dye Acid Red 14 in a microporous tube-in-tube microchannel reactor: decolorization and mechanism. Chemosphere 89(2):190–197

Li WP, **a FS, Qin HY et al (2019) Numerical and experimental investigations of micromixing performance and efficiency in a pore-array intensified tube-in-tube microchannel reactor. ChemEng J 370:1350–1365

Li WP, **a FS, Zhao SC et al (2019) Mixing performance of an inline high-shear mixer with a novel pore-array liquid distributor. IndEngChem Res 58(44):20213–20225

Li WP, **a FS, Zhao SC et al (2019) Characterization of liquid–liquid mass transfer performance in a novel pore-array intensified tube-in-tube microchannel. AIChEJ. https://doi.org/10.1002/aic.16893

Linek V, Vacek V (1981) Chemical engineering use of catalyzed sulfite oxidation kinetics for the determination of mass transfer characteristics of gas: liquid contactors. ChemEngSci 36(11):1747–1768

Linek V, Tvrdík J (1971) A generalization of kinetic data on sulphite oxidation systems. BiotechnolBioeng 13(3):353–369

Rischbieter E, Schumpe A, Wunder V (1996) Gas solubilities in aqueous solutions of organic substances. J ChemEng Data 41(4):809–812

Akita K (1981) Diffusivities of gases in aqueous electrolyte solutions. IndEngChem Fund 20(1):89–94

Li WL, Ouyang Y, Gao XY et al (2018) CFD analysis of gas–liquid flow characteristics in a microporous tube-in-tube microchannel reactor. Comput Fluids 170:13–23

Tan J, Lu YC, Xu JH et al (2012) Mass transfer characteristic in the formation stage of gas–liquid segmented flow in microchannel. ChemEng J 185–186:314–320

Li GX, Shang MJ, Song Y et al (2018) Characterization of liquid-liquid mass transfer performance in a capillary microreactor system. AIChE J 64(3):1106–1116

Tang M, Zhang SF, Wang DW et al (2019) CFD simulation of gas flow field distribution and design optimization of the tridimensional rotational flow sieve tray with different structural parameters. ChemEngSci 201:34–49

Mandal SN, Das SK (2003) Gas–liquid flow through helical coils in vertical orientation. IndEngChem Res 42(14):3487–3494

Luo JZ, Chu GW, Luo Y et al (2017) Regulating the micromixing efficiency of a novel helical tube reactor by premixing behavior optimization. AIChE J 63(7):2876–2887

Pan MY, Qian Z, Shao L et al (2014) Absorption of carbon dioxide into N-methyldiethanolamine in a high-throughput microchannel reactor. Sep PurifTechnol 125:52–58

Acknowledgements

This work was supported by National Key Research and Development Program (No. 2016YFD0501402-04), National Natural Science Foundation of China (Nos. 21776179, 21621004), and the Program for Changjiang Scholars and Innovative Research Team in University (No. IRT_15R46).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

**a, F., Li, W., Guo, J. et al. Gas Absorption and Mass Transfer in a Pore-Array Intensified Tube-in-Tube Microchannel. Trans. Tian** Univ. 27, 409–421 (2021). https://doi.org/10.1007/s12209-020-00248-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12209-020-00248-6