Abstract

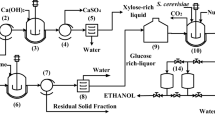

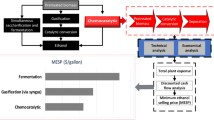

In the process of poplar fermentation for ethanol, different methods are adopted to achieve efficient treatment and resource utilization of fermentation residues, which meets the current demand for green energy and carbon neutrality. Therefore, this work aims to establish an evaluation method on energy consumption, pollutant emissions, and cost expenditures in the production process for biofuels from poplar wood and residue. The process was simulated with commercial software (Aspen Plus for chemical production simulation and cost estimation and eBalance for LCA). Results showed that compared to FCE, it made a higher conversion efficiency of CFG because of the biojet fuel and gasoline from the gasification and conversion of residual lignin. And the flash evaporator, hydrolysis reactor, and fermentation reactor were components with the highest exergy loss. The economic cost of CFG was 9.63% less than that of FCE, and cellulase enzymes and poplar wood in variable costs were main factors in the total cost. Comparing environmental impacts from four perspectives, it was found that the total comprehensive impact of FCE was higher than that of CFG under each weight. The degree of influence of the first level indicator layer was energy consumption, environmental impact, and economic cost in descending order.

Graphical Abstract

Similar content being viewed by others

Data Availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- AP:

-

Acidizing potential

- AHP:

-

Analytic hierarchy process

- CEPCI:

-

Chemical Engineering Equipment Cost Index

- CF:

-

Clinker fermentation

- CFG:

-

Coupled fermentation-gasification for liquid fuel system

- CLCD:

-

Chinese life cycle database

- CML:

-

Centrum voor Milieukunde Leiden

- COD:

-

Chemical oxygen demand

- EP:

-

Eutrophication potential

- ERs:

-

Equivalence ratios

- FCE:

-

Fermentation of cellulosic biomass for ethanol system

- FDP:

-

Fossil depletion potential

- FP-H:

-

Fast pyrolysis and hydrogenation upgrading system

- FT:

-

Fischer-Tropsch

- G-FT:

-

Gasification Fischer–Tropsch synthesis system

- GSA:

-

Gasification synthesis for aviation fuel system

- GWP:

-

Global warming potential

- HC:

-

Hydrocarbons

- HTP:

-

Human toxicity potential

- LCA:

-

Life cycle assessment

- NTotal :

-

Total nitrogen

- PM10 :

-

Particle matter (< 10 μm)

- POCP:

-

Photochemical oxidation potential

- POF:

-

Photochemical ozone formation

- RK-SOAVE:

-

Redlik Kwong-Soave equation of state

- RMF:

-

Raw material fermentation

- SHF:

-

Sequential hydrolysis fermentation

- SSCF:

-

Simultaneous saccharification and co-fermentation

- SSF:

-

Simultaneous saccharification fermentation

- SW:

-

Solid waste potential

- TPEC:

-

Total purchase equipment cost

- TPI:

-

Total purchase investment

- VOC:

-

Volatile organic compounds

References

de Melo FM, Silvestre A, Carvalho M (2019) Carbon footprints associated with electricity generation from biomass syngas and diesel. Environ Eng Manage J 18(7):1391–1397

Rodionova MV, Bozieva AM, Zharmukhamedov SK, Leong YK, Lan JCW, Veziroglu A, Veziroglu TN, Tomo T, Chang JS, Allakhverdiev SI (2022) A comprehensive review on lignocellulosic biomass biorefinery for sustainable biofuel production. Int J Hydrogen Energy 47(3):1481–1498. https://doi.org/10.1016/j.ijhydene.2021.10.122

Schubert T (2020) Production routes of advanced renewable C1 to C4 alcohols as biofuel components - a review. Biofuels Bioproducts Biorefining-Biofpr 14(4):845–878. https://doi.org/10.1002/bbb.2109

Raj T, Chandrasekhar K, Kumar AN, Banu JR, Yoon JJ, Bhatia SK, Yang YH, Varjani S, Kim SH (2022) Recent advances in commercial biorefineries for lignocellulosic ethanol production: current status, challenges and future perspectives. Bioresour Technol 344. https://doi.org/10.1016/j.biortech.2021.126292

Perez-Almada D, Galan-Martin A, del Mar CM, Castro E (2023) Integrated techno-economic and environmental assessment of biorefineries: review and future research directions. Sustain Energ Fuels 7(17):4031–4050. https://doi.org/10.1039/d3se00405h

Kordala N, Walter M, Brzozowski B, Lewandowska M (2022) 2G-biofuel ethanol: an overview of crucial operations, advances and limitations. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-022-02861-y

Hou JJ, Zhang XT, Liu SJ, Zhang SD, Zhang QZ (2020) A critical review on bioethanol and biochar production from lignocellulosic biomass and their combined application in generation of high-value byproducts. Energy Technol 8(5). https://doi.org/10.1002/ente.202000025

Wang F, Ouyang D, Zhou Z, Page SJ, Liu D, Zhao X (2021) Lignocellulosic biomass as sustainable feedstock and materials for power generation and energy storage. J Energy Chem 57:247–280. https://doi.org/10.1016/j.jechem.2020.08.060

Nagarajan D, Lee D-J, Chang J-S (2019) Recent insights into consolidated bioprocessing for lignocellulosic biohydrogen production. Int J Hydrogen Energy 44(28):14362–14379. https://doi.org/10.1016/j.ijhydene.2019.03.066

Sharma S, Nair A, Sarma SJ (2021) Biorefinery concept of simultaneous saccharification and co-fermentation: challenges and improvements. Chem Eng Process 169. https://doi.org/10.1016/j.cep.2021.108634

Shen GN, Yuan XC, Chen ST, Liu SM, ** MJ (2022) High titer cellulosic ethanol production from sugarcane bagasse via DLCA pretreatment and process development without washing/detoxifying pretreated biomass. Renew Energ 186:904–913. https://doi.org/10.1016/j.renene.2022.01.062

Akbarian A, Andooz A, Kowsari E, Ramakrishna S, Asgari S, Cheshmeh ZA (2022) Challenges and opportunities of lignocellulosic biomass gasification in the path of circular bioeconomy. Bioresour Technol 362. https://doi.org/10.1016/j.biortech.2022.127774

Timofeeva SS, Karaeva JV, Kovalev AA, Kovalev DA, Litti YV (2023) Steam gasification of digestate after anaerobic digestion and dark fermentation of lignocellulosic biomass to produce syngas with high hydrogen content. Int J Hydrogen Energy 48(21):7559–7568. https://doi.org/10.1016/j.ijhydene.2022.11.260

Valdes CF, Gomez CA, Ortiz M, Mena D, Ruiz R, Cogollo K, Mira J, Chejne F (2023) Thermochemical evaluation of fique bagasse waste (FBW) resulting from industrial processes as an energy precursor through combustion and gasification. Biomass Convers Biorefin 13(7):5501–5514. https://doi.org/10.1007/s13399-021-01700-w

Im-orb K, Arpornwichanop A (2022) Comparative techno-economic assessment of bio-methanol and bio-DME production from oil palm residue. Energy Convers Manage 258. https://doi.org/10.1016/j.enconman.2022.115511

Joseph AM, Tulasi Y, Shrivastava D, Kiran B (2023) Techno-economic feasibility and exergy analysis of bioethanol production from waste. Energy Convers Manage: X 18. https://doi.org/10.1016/j.ecmx.2023.100358

Michailos S, Parker D, Webb C (2017) A techno-economic comparison of Fischer-Tropsch and fast pyrolysis as ways of utilizing sugar cane bagasse in transportation fuels production. Chem Eng Res Des 118:206–214. https://doi.org/10.1016/j.cherd.2017.01.001

Chen J, Liu Y, Wu X, Jiaqiang E, Leng E, Zhang F, Liao G (2022) Thermodynamic, environmental analysis and comprehensive evaluation of supercritical water gasification of biomass fermentation residue. J Clean Prod 361. https://doi.org/10.1016/j.jclepro.2022.132126

Zhan L, Zhang X, Zeng Y, Li R, Song X, Chen B (2022) Life cycle assessment of optimized cassava ethanol production process based on operating data from Guangxi factory in China. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-022-03442-9

Szargut J (1988) Energy and exergy analysis of the preheating of combustion reactants. Int J Energy Res 12(1):45–58. https://doi.org/10.1002/er.4440120106

Hao J, **ao J, Song G, Zhang Q (2021) Energy and exergy analysis of bio-jet fuel production from lignocellulosic biomass via aqueous conversion. Case Stud Therm Eng 26:101006. https://doi.org/10.1016/j.csite.2021.101006

Mortaza A, Khounani Z, Hosseinzadeh-Bandbafha H, Gupta VK, Amiri H, Lam SS, Morosuk T, Tabatabaei M (2021) Exergoenvironmental analysis of bioenergy systems: a comprehensive review. Renew Sust Energ Rev 149. https://doi.org/10.1016/j.rser.2021.111399

Usmani Z, Sharma M, Awasthi AK, Sivakumar N, Lukk T, Pecoraro L, Thakur VK, Roberts D, Newbold J, Gupta VK (2021) Bioprocessing of waste biomass for sustainable product development and minimizing environmental impact. Bioresour Technol 322. https://doi.org/10.1016/j.biortech.2020.124548

Sun HR, Luo ZY, Li SM, Xue S, Zhou QG, Wei TY, Du LW (2021) Comparative life cycle assessment (LCA) of biofuel production via corn stover: fermentation to ethanol, pyrolysis to bio-oil, and gasification to jet fuel. Biomass Convers Biorefin 13:12809–12821. https://doi.org/10.1007/s13399-021-02054-z

Zhang X, Hao X, Liu Y, Wu R, Shan X, Li S (2022) Contribution of potential clean trucks in carbon peak pathway of road freight based on scenario analysis: a case study of China. J Clean Prod 379. https://doi.org/10.1016/j.jclepro.2022.134669

Wang W, Zhong Z, Liu Q, **ang Z, Yang Y, Pan X, Shen Z (2023) Process simulation and environmental impact assessment of different cases in hydrothermal catalytic bio-jet fuel production. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-023-04403-6

ISO 14044 (2006) Environmental management Life cycle assessment Requirements and guidelines. https://www.iso.org/standard/38498.html

Im-orb K, Simasatitkul L, Arpornwichanop A (2016) Techno-economic analysis of the biomass gasification and Fischer-Tropsch integrated process with off-gas recirculation. Energy 94:483–496. https://doi.org/10.1016/j.energy.2015.11.012

Zhang Y, Brown TR, Hu G, Brown RC (2013) Techno-economic analysis of monosaccharide production via fast pyrolysis of lignocellulose. Bioresour Technol 127:358–365. https://doi.org/10.1016/j.biortech.2012.09.070

Gutierrez Ortiz FJ (2020) Techno-economic assessment of supercritical processes for biofuel production. J Supercrit Fluids 160. https://doi.org/10.1016/j.supflu.2020.104788

Dos Santos PH, Neves SM, Sant’Anna DO, de Oliveira CH, Carvalho HD (2019) The analytic hierarchy process supporting decision making for sustainable development: an overview of applications. J Cleaner Prod 212:119–138. https://doi.org/10.1016/j.jclepro.2018.11.270

Yadav S, Srivastava G, Yadav P, Giri BS (2020) Prioritization of decentralized renewable energy technologies for rural areas of Bundelkhand Region, India using analytical hierarchy process (AHP). Int J Renew Energy Res 10(4):1793–1801

Cinelli M, Coles SR, Kirwan K (2014) Analysis of the potentials of multi criteria decision analysis methods to conduct sustainability assessment. Ecol Indic 46:138–148. https://doi.org/10.1016/j.ecolind.2014.06.011

Myllyviita T, Holma A, Antikainen R, Lahtinen K, Leskinen P (2012) Assessing environmental impacts of biomass production chains - application of life cycle assessment (LCA) and multi-criteria decision analysis (MCDA). J Cleaner Prod 29–30:238–245. https://doi.org/10.1016/j.jclepro.2012.01.019

John CA, Tan LS, Tan J, Kiew PL, Shariff AM, Halim HNA (2021) Selection of renewable energy in rural area via life cycle assessment-analytical hierarchy process (LCA-AHP): a case study of Tatau, Sarawak. Sustainability 13(21). https://doi.org/10.3390/su132111880

Kabir Kazi F, Fortman J, Anex R, Kothandaraman G, Hsu D, Aden A, Dutta A (2010) Techno-Economic analysis of biochemical scenarios for production of cellulosic ethanol, NREL. https://www.nrel.gov/docs/fy10osti/46588.pdf

Cerone N, Zimbardi F, Contuzzi L, Prestipino M, Carnevale MO, Valerio V (2017) Air-steam and oxy-steam gasification of hydrolytic residues from biorefinery. Fuel Process Technol 167:451–461. https://doi.org/10.1016/j.fuproc.2017.07.027

Yang Y, Ni J-Q, Zhou S, **e GH (2020) Comparison of energy performance and environmental impacts of three corn stover-based bioenergy pathways. J Cleaner Prod 272. https://doi.org/10.1016/j.jclepro.2020.122631

Carnbero C, Sowlati T (2014) Assessment and optimization of forest biomass supply chains from economic, social and environmental perspectives - a review of literature. Renew Sust Energ Rev 36:62–73. https://doi.org/10.1016/j.rser.2014.04.041

Talang RPN, Sirivithayapakorn S (2020) Environmental impacts and economic benefits of different wastewater management schemes for molasses-based ethanol production: a case study of Thailand. J Clean Prod 247. https://doi.org/10.1016/j.jclepro.2019.119141

Tan J, Tan RR, Aviso KB, Promentilla MAB, Sulaiman NMN (2017) Study of microalgae cultivation systems based on integrated analytic hierarchy process-life cycle optimization. Clean Technol Environ Policy 19(8):2075–2088. https://doi.org/10.1007/s10098-017-1390-5

Pongpat P, Mahmood A, Ghani HU, Silalertruksa T, Gheewala SH (2023) Optimization of food-fuel-fibre in biorefinery based on environmental and economic assessment: the case of sugarcane utilization in Thailand. Sustain Prod Consump 37:398–411. https://doi.org/10.1016/j.spc.2023.03.013

Li Y, Wang Y, Wang W, Fatehi P, Kozinski J, Kang K (2023) Analytic hierarchy process-based life cycle assessment of the renewable energy production by orchard residual biomass-fueled direct-fired power generation system. J Clean Prod 419. https://doi.org/10.1016/j.jclepro.2023.138304

de Luna MY, Rodrigues PM, Mabrysa Torres GA, Antonio Eufrazio DCJ, Queiroz MJ, Elaine MS, Alexsandra de Sousa RM (2019) A thermogravimetric analysis of biomass wastes from the northeast region of Brazil as fuels for energy recovery. Energy Sources Part A-Recovery Util Environ Eff 41(13):1557–1572. https://doi.org/10.1080/15567036.2018.1549132

Chen W-H, Lin B-J, Lin Y-Y, Chu Y-S, Ubando AT, Show PL, Ong HC, Chang J-S, Ho S-H, Culaba AB, Petrissans A, Petrissans M (2021) Progress in biomass torrefaction: principles, applications and challenges. Progr Energy Combust Sci 82. https://doi.org/10.1016/j.pecs.2020.100887

Esteves B, Sen U, Pereira H (2023) Influence of chemical composition on heating value of biomass: a review and bibliometric analysis. Energies 16(10). https://doi.org/10.3390/en16104226

Vasquez MC, Silva EE, Castillo EF (2017) Hydrotreatment of vegetable oils: a review of the technologies and its developments for jet biofuel production. Biomass Bioenerg 105:197–206. https://doi.org/10.1016/j.biombioe.2017.07.008

Ubando AT, Rivera DRT, Chen W-H, Culaba AB (2019) A comprehensive review of life cycle assessment (LCA) of microalgal and lignocellulosic bioenergy products from thermochemical processes. Bioresour Technol 291. https://doi.org/10.1016/j.biortech.2019.121837

Wang W-C, Tao L (2016) Bio-jet fuel conversion technologies. Renew Sust Energ Rev 53:801–822. https://doi.org/10.1016/j.rser.2015.09.016

Patel M, Zhang X, Kumar A (2016) Techno-economic and life cycle assessment on lignocellulosic biomass thermochemical conversion technologies: a review. Renew Sust Energ Rev 53:1486–1499. https://doi.org/10.1016/j.rser.2015.09.070

Kargbo H, Harris JS, Phan AN (2021) “Drop-in” fuel production from biomass: critical review on techno-economic feasibility and sustainability. Renew Sust Energ Rev 135. https://doi.org/10.1016/j.rser.2020.110168

Funding

This work was supported by the National Key Research and Development Program of China No. 2018YFB1501405. The authors would like to acknowledge the support of Ministry of Science and Technology of the People’s Republic of China.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Software simulation, formal analysis, and writing—original draft: Wei Wang; methodology, project administration, funding acquisition, and writing—review and editing: Zhao** Zhong; supervision and resources: **aoming Bao; validation and conceptualization: **aotian Pan; investigation and data analysis: **ang Zheng; writing—review and editing: Yuxuan Yang; data curation and data analysis: Zhaocheng Shen. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

Comprehensive evaluation method was established on exergy analysis, LCA, and economic cost.

Biojet fuel and gasoline were produced by gasification from fermentation residue in CFG.

Environment impact was significantly related with the utilization of fermentation residue.

By-products covered a portion of economic costs in the production of biofuels.

Total comprehensive impact of FCE was higher than that of CFG under each weight.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, W., Zhong, Z., Bao, X. et al. Comprehensive Evaluation of Biofuels from the Fermentation of Poplar Wood and the Gasification of Fermentation Residue. Bioenerg. Res. (2024). https://doi.org/10.1007/s12155-024-10760-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12155-024-10760-5