Abstract

Brewer’s spent grain (BSG) is a major by-product in the beer-brewing process which contributes to 85% of the entire generated by-product in the brewing process. BSG is rich in proteins, and most of the malt proteins (74–78%) remain insoluble in BSG after the mashing process. Solid-state fermentation (SSF) is a promising bioprocess that enables microorganisms to survive in environments with minimal water and has shown to enhance the nutritional composition of BSG. In this review, the potential application of protein, amino acids (proline, threonine, and serine), phenolic contents, and soluble sugars (glucose, fructose, xylose, arabinose, and cellobiose) extracted from BSG by various microorganisms using SSF is explored. Incorporation of BSG into animal feed, human diets, and as a substrate for microorganisms are the prospects that could be implemented in the industrial scale. This review also discussed various advances to improve the fermentation yield such as symbiotic fermentation, the addition of nitrogen supplements, and an optimal mixture of the agro-industrial waste substrate. Future perspectives on SSF are also addressed to provide important ideas for immediate and future studies. However, challenges include optimizing SSF conditions and design of bioreactors, and operational costs must be addressed in the future to overcome current obstacles. Overall, this mini review highlights the potential benefits of BSG utilization and SSF in a sustainable way.

Graphical Abstract

Similar content being viewed by others

Abbreviations

- BSG:

-

Brewer’s spent grain

- HMF:

-

5-Hydroxymethyl furfural

- SmF:

-

Submerged fermentation

- SSF:

-

Solid-state fermentation

- TCA:

-

Tricarboxylic acid

- DH:

-

Degree of hydrolysis

- TPC:

-

Total phenolic content

- DPPH:

-

2,2-Diphenyl-1-picrylhydrazyl

- TOC:

-

Total organic carbon

- GAE:

-

Gallic acid equivalents

- TE:

-

Trolox equivalents

References

Guido, L., & Moreira, M. (2017). Techniques for extraction of brewer’s spent grain polyphenols: A review. Food and Bioprocess Technology, 10(7), 1192–1209.

Nasir, N. (2019). Hydrothermal liquefaction of lignocellulosic biomass. PhD thesis, University of Sheffield.

Verni, M, Pontonio, E, Krona, A, Jacob, S, Pinto, D, Rinaldi, F, Verardo, V, Díaz-de-Cerio, E, Coda, R & Rizzello, C. (2020). Bioprocessing of brewers’ spent grain enhances its antioxidant activity: characterization of phenolic compounds and bioactive peptides. Frontiers in Microbiology, 11.

Kavalopoulos, M., Stoumpou, V., Christofi, A., Mai, S., Barampouti, E. M., Moustakas, K., Malamis, D., & Loizidou, M. (2021). Sustainable valorisation pathways mitigating environmental pollution from brewers’ spent grains. Environmental Pollution, 270, 116069.

Martín, D. S., Orive, M., Iñarra, B., Castelo, J., Estévez, A., Nazzaro, J., Iloro, I., Elortza, F., & Zufía, J. (2020). Brewers’ spent yeast and grain protein hydrolysates as second-generation feedstuff for Aquaculture feed. Waste and Biomass Valorization, 11(10), 5307–5320.

Rojas-Chamorro, J. A., Cara, C., Romero, I., Castro, E., Romero-García, J. M., & Mussatto, S. I. (2018). Ethanol production from brewers’ spent grain pretreated by dilute phosphoric acid. Energy & Fuels, 32(4), 5226–5233.

Aboltins, A., & Palabinskis, J. (2015). Research in brewer’s spent grain drying process. Engineering for Rural Development, 5, 230–235.

Teixeira, M. R., Guarda, E. C., Freitas, E. F., Galinha, C. F., Duque, A. F., & Reis, M. A. (2020). Valorization of raw brewers’ spent grain through the production of volatile fatty acids. New Biotechnology, 57, 4–10.

Buffington, J. (2014). The economic potential of brewer’s spent grain (BSG) as a biomass feedstock. Advances in Chemical Engineering and Science, 4(3), 308–318.

Lynch, K., Steffen, E., & Arendt, E. (2016). Brewers’ spent grain: A review with an emphasis on food and health. Journal of the Institute of Brewing, 122(4), 553–568.

Farcas, A., Socaci, S., Mudura, E., Dulf, F., Vodnar, D. C., Tofana, M., & Salanță, L. C. (2017). Exploitation of Brewing Industry Wastes to Produce Functional Ingredients. InTech EBooks. https://doi.org/10.5772/intechopen.69231

Cooray, S, Lee, J & Chen, W. (2017). Evaluation of brewers’ spent grain as a novel media for yeast growth. AMB Express, 7(1). https://doi.org/10.1186/s13568-017-0414-1

**ros, C., & Christakopoulos, P. (2012). Biotechnological potential of brewers spent grain and its recent applications. Waste and Biomass Valorization, 3(2), 213–232.

Coronado, M., Montero, G., Montes, D., Valdez-Salas, B., Ayala, J., García, C., Carrillo, M., León, J., & Moreno, A. (2020). Physicochemical characterization and SEM-EDX analysis of brewer’s spent grain from the craft brewery industry. Sustainability, 12(18), 7744.

Jackowski, M., Niedźwiecki, Ł, Jagiełło, K., Uchańska, O., & Trusek, A. (2020). Brewer’s spent grains—valuable beer industry by-product. Biomolecules, 10(12), 1669.

Su, Y., et al. (2015). Fractional pretreatment of lignocellulose by alkaline hydrogen peroxide: Characterization of its major components. Food and Bioproducts Processing, 94, 322–330.

Marta, K., et al. (2020). Evaluation of ultrasound pretreatment for enhanced anaerobic digestion of Sida hermaphrodita. BioEnergy Research, 13(3), 824–832.

Beldman, G., Hennekam, J., & Voragen, A. G. (1987). Enzymatic hydrolysis of beer brewers’ spent grain and the influence of pretreatments. Biotechnology and Bioengineering, 30(5), 668–671.

Taylor, M. S., Alabdrabalameer, H. A., & Skoulou, V. (2019). Choosing physical, physicochemical and chemical methods of pre-treating lignocellulosic wastes to repurpose into solid fuels. Sustainability, 11(13), 3604.

Menon, V., & Rao, M. (2012). Trends in bioconversion of lignocellulose: Biofuels, platform chemicals & biorefinery concept. Progress in Energy and Combustion Science, 38(4), 522–550.

Zhengdao, Y., Bailiang, Z., Yu, F., Xu, G., & Song, A. (2012). A real explosion: The requirement of steam explosion pretreatment. Bioresource Technology, 121, 335–341.

Zhuang, X., Wang, W., Yu, Q., Qi, W., Wang, Q., Tan, X., Zhou, G., & Yuan, Z. (2016). Liquid hot water pretreatment of lignocellulosic biomass for bioethanol production accompanying with high valuable products. Bioresource Technology, 199, 68–75.

Zheng, Y., Lin, H., & Tsao, G. T. (1998). Pretreatment for cellulose hydrolysis by carbon dioxide explosion. Biotechnology Progress, 14(6), 890–896.

Chen, S., Zhang, X., Singh, D., Yu, H., & Yang, X. (2010). Biological pretreatment of lignocellulosics: Potential, progress and challenges. Biofuels, 1(1), 177–199.

Kumar, V., Yadav, S., Kumar, J., & Ahluwalia, V. (2020). A critical review on current strategies and trends employed for removal of inhibitors and toxic materials generated during biomass pretreatment. Bioresource Technology, 299, 122633.

Mussatto, S. (2004). Alternatives for detoxification of diluted-acid lignocellulosic hydrolyzates for use in fermentative processes: A review. Bioresource Technology, 93(1), 1–10.

Harmsen, P., Huijgen, W. J. J., Bermudez, L., & Bakker, R. (2010). Literature review of physical and chemical pretreatment processes for lignocellulosic biomass. Wageningen UR-Food & Biobased Research. No. 1184. https://edepot.wur.nl/150289

Zabed, H. M., Akter, S., Yun, J., Zhang, G., Awad, F. N., Qi, X., & Sahu, J. N. (2019). Recent advances in biological pretreatment of microalgae and lignocellulosic biomass for biofuel production. Renewable & Sustainable Energy Reviews, 105, 105–128.

Masran, R., Zanirun, Z., Shirosaki, Y., Ibrahim, M. N. M., Yee, P. L., & Abd-Aziz, S. (2016). Harnessing the potential of ligninolytic enzymes for lignocellulosic biomass pretreatment. Applied Microbiology and Biotechnology, 100(12), 5231–5246.

Rezania, S., Oryani, B., Park, J., Talaiekhozani, A., Sabbagh, F., Hashemi, B., Rupani, P. F., & Mohammadi, A. (2020). Different pretreatment technologies of lignocellulosic biomass for bioethanol production: An overview. Energy, 199, 117457.

Turet, J. L., Martínez-Avila, O., Serrano, E. S., Corchado-Lopo, C., Llenas, L., Salas, S. F. R., & Gea, T. (2020). Brewer’s spent grain biotransformation to produce lignocellulolytic enzymes and polyhydroxyalkanoates in a two-stage valorization scheme. Biomass Conversion and Biorefinery, 12(9), 3921–3932.

Guo, H., Wu, S., Tian, Y., Zhang, J., & Liu, H. (2021). Application of machine learning methods for the prediction of organic solid waste treatment and recycling processes: A review. Bioresource Technology, 319, 124114.

Chaitanya Reddy, C., Khilji, I., Gupta, A., Bhuyar, P., Mahmood, S., Saeed AL-Japairai, K., & Chua, G. (2021). Valorization of keratin waste biomass and its potential applications. Journal of Water Process Engineering, 40, 101707.

Cooray, S., & Chen, W. (2018). Valorization of brewer’s spent grain using fungi solid-state fermentation to enhance nutritional value. Journal of Functional Foods, 42, 85–94.

Chetrariu, A., & Dabija, A. (2020). Brewer’s spent grains: Possibilities of valorization, a review. Applied Sciences, 10(16), 5619.

Subramaniyam, R. S., & Vimala, R. (2012). Solid state and submerged fermentation for the production of bioactive substances: a comparative study. International Journal of Science and Nature, 3(3), 480–486.

Soccol, C. R., et al. (2017). Recent developments and innovations in solid state fermentation. Biotechnology Research and Innovation, 1(1), 52–71.

Doriya, K. et al. (2016). Solid-state fermentation vs submerged fermentation for the production of L-asparaginase. Marine Enzymes Biotechnology: Production and Industrial Applications, Part I - Production of Enzymes, 115–135.

Hashemi, M., et al. (2011). The potential of Brewer’s spent grain to improve the production of α-amylase by bacillus sp. KR-8104 in submerged fermentation system. New Biotechnology, 28(2), 165–172.

Angel, S. J., Kavitha, C., Vidyadharani, G., Roy, P., & Dhandapani, R. (2012). Isolation of inulinase producing bacteria from sugarcane soil. International Journal of Applied Biology and Pharmaceutical Technology.

Zherebtsov, N. A., Shelamova, S. A., & Abramova, I. N. (2002). Biosynthesis of inulinases by Bacillus bacteria. Applied Biochemistry and Microbiology, 38, 544–548.

Singh, R. B., Chauhan, K., & Kennedy, J. F. (2017). A panorama of bacterial inulinases: Production, purification, characterization and industrial applications. International Journal of Biological Macromolecules, 96, 312–322.

Brierley, M. R., & Steel, R. (1959). Agitation-aeration in submerged fermentation. Applied Microbiology, 7(1), 57–61.

Weuster-Botz, D., Hekmat, D., Puskeiler, R., & Franco-Lara, E. (2006). Enabling technologies: fermentation and downstream processing. In Springer eBooks, 205–247.

Olukomaiya, O. O., Fernando, C., Mereddy, R., Li, X., & Sultanbawa, Y. (2019). Solid-state fermented plant protein sources in the diets of broiler chickens: A review. Animal Nutrition, 5(4), 319–330.

Mitri, S., Salameh, S., Khelfa, A., Leonard, E., Maroun, R., Louka, N., & Koubaa, M. (2022). Valorization of brewers’ spent grains: Pretreatments and fermentation, a review. Fermentation, 8(2), 50.

Šelo, G., Planinić, M., Tišma, M., Tomas, S., Koceva Komlenić, D., & Bucić-Kojić, A. (2021). A comprehensive review on valorization of agro-food industrial residues by solid-state fermentation. Foods, 10(5), 927.

Webb, C. (2017). Design aspects of solid-state fermentation as applied to microbial bioprocessing. Journal of Applied Biotechnology & Bioengineering, 4(1).

Sim, T., & Oh, J. C. S. (1990). Spent brewery grains as substrate for the production of cellulases by Trichoderma reesei QM9414. Journal of Industrial Microbiology, 5(2–3), 153–158.

Onyimba, I. A., Ogbonna, C. I. C., Akueshi, C. O., & Chukwu, C. O. (2009). Changes in the nutrient composition of brewery spent grain subjected to solid state natural fermentation. Nigerian Journal of Biotechnology, 20(1), 55–60.

Iyayi, E. A., & Aderolu, Z. A. (2003). Enhancement of the feeding value of some agro-industrial by-products for laying hens after their solid state fermentation with Trichoderma viride. African Journal of Biotechnology, 3(3), 182–185.

Zeng, J., Sheng, F., Hu, X., Huang, Z., Tian, X., & Wu, Z. (2022). Nutrition promotion of brewer’s spent grain by symbiotic fermentation adding Bacillus velezensis and Levilactobacillus brevis. Food Bioscience, 49, 101941.

da Costa Maia, I., dos Thomaz D’Almeida, S. C., Guimarães Freire, D., d’Avila Costa Cavalcanti, E., Cameron, L., Furtado Dias, J., & Simões Larraz Ferreira, M. (2020). Effect of solid-state fermentation over the release of phenolic compounds from brewer’s spent grain revealed by UPLC-MSE. LWT, 133, 110136.

Leite, P., Belo, I., & Salgado, J. (2021). Co-management of agro-industrial wastes by solid-state fermentation for the production of bioactive compounds. Industrial Crops and Products, 172, 113990.

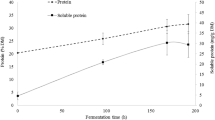

Zeng, J., Huang, W., Tian, X., Hu, X., & Wu, Z. (2021). Brewer’s spent grain fermentation improves its soluble sugar and protein as well as enzymatic activities using Bacillus velezensis. Process Biochemistry, 111, 12–20.

Tišma, M., Jurić, A., Bucić-Kojić, A., Panjičko, M., & Planinić, M. (2018). Biovalorization of brewers’ spent grain for the production of laccase and polyphenols. Journal of the Institute of Brewing, 124(2), 182–186.

Wang, X., Xu, Y., Teo, S. Q., Heng, C. W., Lee, D. P. S., Gan, A. X., & Kim, J. E. (2023). Impact of solid-state fermented Brewer’s spent grains incorporation in biscuits on nutritional, physical and sensorial properties. LWT, 182, 114840.

Goh, L. L., & Ken, C. L. L. (2021). Biovalorisation of brewer’s spent grain (BSG) and sensory evaluation of BSG bread. Agriculture and Food Chemistry. https://doi.org/10.26434/chemrxiv.14491842.v1

Fernandes, H., Castro, C., Salgado, J., Filipe, D., Moyano, F., Ferreira, P., Oliva-Teles, A., Belo, I., & Peres, H. (2022). Application of fermented brewer’s spent grain extract in plant-based diets for European seabass juveniles. Aquaculture, 552, 738013.

Verduzco-Oliva, R., & Gutiérrez-Uribe, J. A. (2020). Beyond enzyme production: Solid state fermentation (SSF) as an alternative approach to produce antioxidant polysaccharides. Sustainability, 12(2), 495.

Dey, T. B., Chakraborty, S., Jain, K. K., Sharma, A., & Kuhad, R. C. (2016). Antioxidant phenolics and their microbial production by submerged and solid-state fermentation process: A review. Trends in Food Science and Technology, 53, 60–74.

Gupta, V. K., Kubicek, C. P., Berrin, J., Wilson, D., Couturier, M., Berlin, A., Filho, E. X. F., & Ezeji, T. C. (2016). Fungal enzymes for bio-products from sustainable and waste biomass. Trends in Biochemical Sciences, 41(7), 633–645.

Nigam, P. S. N., & Pandey, A. (2009). Solid-state fermentation technology for bioconversion of biomass and agricultural residues. In Springer eBooks, 197–221.

Pandey, A. (1991). Aspects of fermenter design for solid-state fermentations. Process Biochemistry, 26(6), 355–361.

Alves, L., Coelho, E. A., Romaní, A., & Domingues, L. (2019). Intensifying ethanol production from brewer’s spent grain waste: Use of whole slurry at high solid loadings. New Biotechnology, 53, 1–8.

De Castro, A. M., Castilho, L. R., & Freire, D. M. G. (2015). Performance of a fixed-bed solid-state fermentation bioreactor with forced aeration for the production of hydrolases by Aspergillus awamori. Biochemical Engineering Journal, 93, 303–308.

Ashok, A., Doriya, K., Rao, D. V., & Kumar, D. S. (2017). Design of solid state bioreactor for industrial applications: An overview to conventional bioreactors. Biocatalysis and Agricultural Biotechnology, 9, 11–18.

Moteshafi, H., Mousavi, S. M., & Hashemi, M. (2019). Aeration challenge in high BSG suspended fermentation: Impact of stirred-tank bioreactor scale. Biomass & Bioenergy, 130, 105386.

Zhao, L., Sun, G., Jiang, J., Chen, L., & Huang, J. (2021). Role of microbubbles coupling fibrous-bed bioreactor in butyric acid production by Clostridium tyrobutyricum using Brewer’s spent grain as feedstock. Biochemical Engineering Journal, 172, 108051.

Raghavarao, K., Ranganathan, T. V., & Karanth, N. G. (2003). Some engineering aspects of solid-state fermentation. Biochemical Engineering Journal, 13(2–3), 127–135.

Canoy Postigo, L., Jacobo-Velázquez, D., Guajardo-Flores, D., Garcia Amezquita, L., & García-Cayuela, T. (2021). Solid-state fermentation for enhancing the nutraceutical content of agrifood by-products: recent advances and its industrial feasibility. Food Bioscience, 41, 100926.

Canedo, M., de Paula, F., da Silva, F., & Vendruscolo, F. (2016). Protein enrichment of brewery spent grain from Rhizopus oligosporus by solid-state fermentation. Bioprocess and Biosystems Engineering, 39(7), 1105–1113.

Bisaria, R., Madan, M., & Vasudevan, P. (1997). Utilisation of agro-residues as animal feed through bioconversion. Bioresource Technology, 59(1), 5–8.

Ibarruri, J., Cebrián, M., & Hernández, I. (2019). Solid state fermentation of brewer’s spent grain using Rhizopus sp to enhance Nutritional value. Waste and Biomass Valorization, 10(12), 3687–3700.

FazeliNejad, S., Ferreira, J., Brandberg, T., Lennartsson, P., & Taherzadeh, M. (2016). Fungal protein and ethanol from lignocelluloses using Rhizopus pellets under simultaneous saccharification, filtration and fermentation (SSFF). Biofuel Research Journal, 3(1), 372–378.

Ibarruri, J., & Hernández, I. (2018). Rhizopus oryzae as fermentation agent in food derived sub-products. Waste and Biomass Valorization, 9(11), 2107–2115.

Sousa, D., Venâncio, A., Belo, I., & Salgado, J. (2018). Mediterranean agro-industrial wastes as valuable substrates for lignocellulolytic enzymes and protein production by solid-state fermentation. Journal of the Science of Food and Agriculture, 98(14), 5248–5256.

Ogunjobi, A. A., Mejeha, O. K., & Fagade, O. E. (2011). Protein enrichment of brewery spent grains using Aspergillus oryzae. AU Journal of Technology, 15(1), 53–56.

Duarte, L., Carvalheiro, F., Lopes, S., Neves, I., & Gírio, F. (2007). Yeast biomass production in brewery’s spent grains hemicellulosic hydrolyzate. Applied Biochemistry and Biotechnology, 148(1–3), 119–129.

Bundhoo, Z., & Mohee, R. (2018). Ultrasound-assisted biological conversion of biomass and waste materials to biofuels: A review. Ultrasonics Sonochemistry, 40, 298–313.

Tan, Y., Mok, W., Lee, J., Kim, J., & Chen, W. (2019). Solid state fermentation of brewers’ spent grains for improved nutritional profile using Bacillus subtilis WX-17. Fermentation, 5(3), 52.

Newsholme, P., Stenson, L., Sulvucci, M., Sumayao, R., & Krause, M. (2011). Amino acid metabolism. Comprehensive Biotechnology, 3–14. https://doi.org/10.1016/b978-0-444-64046-8.00002-1

Waters, D. L., Jacob, F., Titze, J., Arendt, E. K., & Zannini, E. (2012). Fibre, protein and mineral fortification of wheat bread through milled and fermented brewer’s spent grain enrichment. European Food Research and Technology, 235(5), 767–778.

Kim, J. K., Lee, M., Ji, G. E., Lee, Y., & Hwang, K. C. (2009). Production of γ-aminobutyric acid in black raspberry juice during fermentation by Lactobacillus brevis GABA100. International Journal of Food Microbiology, 130(1), 12–16.

Hasegawa, M., Yamane, D., Funato, K., Yoshida, A., & Sambongi, Y. (2018). Gamma-aminobutyric acid fermentation with date residue by a lactic acid bacterium, Lactobacillus brevis. Journal of Bioscience and Bioengineering, 125(3), 316–319.

De Lima, L. J. L. F. (2009). Modelo de inferência para a estimação da umidade do leito de um biorreator de fermentação no estado sólido. https://hdl.handle.net/1884/24023

Lareo, C., Sposito, A. P. B., Bossio, A. L., & Volpe, D. C. (2006). Characterization of growth and sporulation of Mucor bacilliformis in solid state fermentation on an inert support. Enzyme and Microbial Technology, 38(3–4), 391–399.

Suhet, M. I., & Fioreze, R. (2011). Produção de proteína unicelular a partir do resíduo da industrialização do abacaxi utilizando fermentação em estado semi-sólido. Revista Brasileira De Tecnologia Agroindustrial, 5(2).

Tsai, C., Lin, L. J., Wang, C., Tsai, C., Chang, S., & Lee, T. (2021). Assessment of intestinal immunity and permeability of broilers on partial replacement diets of two-stage fermented soybean meal by Bacillus velezensis and Lactobacillus brevis ATCC 367. Animals, 11(8), 2336.

Del Carmen Flores-Miranda, M., Luna-González, A., Cortés-Espinosa, D. V., Álvarez-Ruiz, P., Cortés-Jacinto, E., Valdez-González, F. J., & González-Ocampo, H. A. (2015). Effects of diets with fermented duckweed (Lemna sp.) on growth performance and gene expression in the Pacific white shrimp. Litopenaeus vannamei. Aquaculture International, 23(2), 547–561.

Zhang, D., Zhang, Y., Liu, B., Jiang, Y., Zhou, Q., Wang, J. J., Wang, H., **e, J., & Kuang, Q. (2017). Effect of replacing fish meal with fermented mushroom bran hydrolysate on the growth, digestive enzyme activity, and antioxidant capacity of allogynogenetic crucian carp (Carassius auratus gibelio). Turkish Journal of Fisheries and Aquatic Sciences, 17(5), 1039–1048.

Jannathulla, R., Dayal, J. S., Vasanthakumar, D., Ambasankar, K., & Muralidhar, M. (2017). Effect of fermentation methods on amino acids, fiber fractions and anti nutritional factors in different plant protein sources and essential amino acid index for Penaeus (Litopenaeus) vannamei. Indian Journal of Fisheries, 64(2).

Van Doan, H., Hoseinifar, S. H., Dawood, M. A., Chitmanat, C., & Tayyamath, K. (2017). Effects of Cordyceps militaris spent mushroom substrate and Lactobacillus plantarum on mucosal, serum immunology and growth performance of Nile tilapia (Oreochromis niloticus). Fish & Shellfish Immunology, 70, 87–94.

Elsabagh, M., Mohamed, R. A., Moustafa, E. M., Hamza, A. M., Farrag, F., Decamp, O., Dawood, M. A., & Eltholth, M. (2018). Assessing the impact of Bacillus strains mixture probiotic on water quality, growth performance, blood profile and intestinal morphology of Nile tilapia. Oreochromis niloticus. Aquaculture Nutrition, 24(6), 1613–1622.

Dawood, M. A., Koshio, S., Ishikawa, M., Yokoyama, S., Dawood, M. A., Hossain, M. S., Nhu, T. H., Moss, A. S., Dossou, S., & Wei, H. (2017). Dietary supplementation of β-glucan improves growth performance, the innate immune response and stress resistance of red sea bream. Pagrus major. Aquaculture Nutrition, 23(1), 148–159.

Yanbo, W., & Zirong, X. (2006). Effect of probiotics for common carp (Cyprinus carpio) based on growth performance and digestive enzyme activities. Animal Feed Science and Technology, 127(3–4), 283–292.

Manfredini, P. C., Cavanhi, V. A. F., Costa, J. A. V., & Colla, L. M. (2021). Bioactive peptides and proteases: characteristics, applications and the simultaneous production in solid-state fermentation. Biocatalysis and Biotransformation, 39(5), 360–377.

Aliyu, S., & Bala, M. (2011). Brewer’s spent grain: A review of its potentials and applications. African Journal of Biotechnology, 10(3), 324–331.

Niemi, P., Faulds, C., Sibakov, J., Holopainen, U., Poutanen, K., & Buchert, J. (2012). Effect of a milling pre-treatment on the enzymatic hydrolysis of carbohydrates in brewer’s spent grain. Bioresource Technology, 116, 155–160.

Ong, A., & Ken, C. L. L. (2021). Synergistic Effect of a Mixed Culture in Solid-state Fermentation. Agriculture and Food Chemistry. https://doi.org/10.26434/chemrxiv.14483262.v1

Leite, P., Silva, C., Salgado, J., & Belo, I. (2019). Simultaneous production of lignocellulolytic enzymes and extraction of antioxidant compounds by solid-state fermentation of agro-industrial wastes. Industrial Crops and Products, 137, 315–322.

Georgetti, S. R., Vicentini, F. T. M. C., Yokoyama, C. Y., De Fátima Borin, M., Spadaro, A. C. C., & Fonseca, M. J. V. (2009). Enhanced in vitro and in vivo antioxidant activity and mobilization of free phenolic compounds of soybean flour fermented with different β-glucosidase-producing fungi. Journal of Applied Microbiology, 106(2), 459–466.

Rashid, N., Jamaluddin, A., Ghani, A., Razak, D., Jonit, J., Mansor, A., & Manan, M. (2018). Quantification of phenolic compounds changes by Aspergillus oryzae on rice bran fermentation. Food Research, 3(2), 133–137.

McCarthy, A. J., O’Callaghan, Y. C., Neugart, S., Piggott, C. O., Connolly, A., Jansen, M. A. K., Krumbein, A., Schreiner, M., FitzGerald, R. J., & O’Brien, N. M. (2013). The hydroxycinnamic acid content of barley and brewers’ spent grain (BSG) and the potential to incorporate phenolic extracts of BSG as antioxidants into fruit beverages. Food Chemistry, 141(3), 2567–2574.

Vattem, D. A., Deng, S., Labbe, R. G., & Shetty, K. J. (2004). Phenolic antioxidant mobilization in cranberry pomace by solid-state bioprocessing using food grade fungus Lentinus edodes and effect on antimicrobial activity against select food borne pathogens. Innovative Food Science and Emerging Technologies, 5(1), 81–91.

Mussatto, S. I., & Roberto, I. C. (2006). Chemical characterization and liberation of pentose sugars from brewer’s spent grain. Journal of Chemical Technology & Biotechnology, 81(3), 268–274.

Hassan, S. S., Williams, G. A., & Jaiswal, A. K. (2018). Emerging technologies for the pretreatment of lignocellulosic biomass. Bioresource Technology, 262, 310–318.

Tišma, M., Sudar, M., Vasić-Rački, Đ, & Zelić, B. (2009). Mathematical model for Trametes versicolor growth in submerged cultivation. Bioprocess and Biosystems Engineering, 33(6), 749–758.

Kaur, V. (2004). Incorporation of brewery waste in supplementary feed and its impact on growth in some carps. Bioresource Technology, 91(1), 101–104.

Nazzaro, J., Martin, D. S., Perez-Vendrell, A., Padrell, L., Iñarra, B., Orive, M., & Estévez, A. (2021). Apparent digestibility coefficients of brewer’s by-products used in feeds for rainbow trout (Oncorhynchus mykiss) and gilthead seabream (Sparus aurata). Aquaculture, 530, 735796.

Cermeño, M., Connolly, A., O’Keeffe, M. B., Flynn, C., Laohakunjit, N., Aluko, R. E., & FitzGerald, R. J. (2019). Identification of bioactive peptides from brewers’ spent grain and contribution of Leu/Ile to bioactive potency. Journal of Functional Foods, 60, 103455.

McCarthy, A. J., O’Callaghan, Y. C., Connolly, A., Piggott, C. O., FitzGerald, R. J., & O’Brien, N. M. (2012). Phenolic extracts of brewers’ spent grain (BSG) as functional ingredients – assessment of their DNA protective effect against oxidant-induced DNA single strand breaks in U937 cells. Food Chemistry, 134(2), 641–646.

He, K., Pauli, G. F., Zheng, B., Wang, H., Bai, N., Peng, T., Roller, M., & Zheng, Q. (2006). Cimicifuga species identification by high performance liquid chromatography–photodiode array/mass spectrometric/evaporative light scattering detection for quality control of black cohosh products. Journal of Chromatography A, 1112(1–2), 241–254.

Hole, A. S., Grimmer, S., Jensen, M. S., & Sahlstrøm, S. (2012). Synergistic and suppressive effects of dietary phenolic acids and other phytochemicals from cereal extracts on nuclear factor kappa B activity. Food Chemistry, 133(3), 969–977.

Paraskevakis, N. (2015). Effects of dietary dried Greek oregano (Origanum vulgare ssp. hirtum) supplementation on blood and milk enzymatic antioxidant indices, on milk total antioxidant capacity and on productivity in goats. Animal Feed Science and Technology, 209, 90–97.

Castillo, C., et al. (2013). Effect of supplementation with antioxidants on the quality of bovine milk and meat production. The Scientific World Journal, 2013, 1–8.

Heredia-Sandoval, N. G., Del Carmen Granados-Nevárez, M., De La Barca, A. M. C., Vásquez-Lara, F., Malunga, L. N., Apea-Bah, F. B., Beta, T., & Islas-Rubio, A. R. (2020). Phenolic acids, antioxidant capacity, and estimated glycemic index of cookies added with brewer’s spent grain. Plant Foods for Human Nutrition, 75(1), 41–47.

Reis, S., & Abu-Ghannam, N. (2014). Antioxidant capacity, arabinoxylans content and in vitro glycaemic index of cereal-based snacks incorporated with brewer’s spent grain. Lebensmittel-Wissenschaft & Technologie, 55(1), 269–277.

Simpson, T. J., Scheel, R. A., Nomura, C. T., Ramarao, B. V., & Kumar, D. (2021). Production of polyhydroxybutyrate and polyhydroxybutyrate-co-MCL copolymers from brewer’s spent grains by recombinant Escherichia coli LSBJ. Biomass Conversion and Biorefinery.

Kuhad, R. C., Gupta, R., Khasa, Y. P., Singh, A. K., & Zhang, Y. P. (2011). Bioethanol production from pentose sugars: Current status and future prospects. Renewable & Sustainable Energy Reviews, 15(9), 4950–4962.

Chavan, S., Yadav, B., Tyagi, R. D., & Drogui, P. (2021). A review on production of polyhydroxyalkanoate (PHA) biopolyesters by thermophilic microbes using waste feedstocks. Bioresource Technology, 341, 125900.

Prados, E., & Maicas, S. (2016). Bacterial production of hydroxyalkanoates (PHA). Universal Journal of Microbiology Research, 4(1), 23–30.

Matsakas, L., Mikes, F., & Bühler, S. (2018). Valorization of brewers’ spent grain for the production of lipids by oleaginous yeast. Molecules, 23(12), 3052.

Zachariah, P. (2022). Would you eat Diwali laddoos made with beer waste? Mintlounge. Website: https://lifestyle.livemint.com/food/discover/would-you-eat-diwali-laddoos-made-with-beer-waste-111666324853997.html

McCabe, C. (2022). Portland Pet Food Company turns brew waste into dog treats. KGW8. Website: https://www.kgw.com/article/life/pets/portland-pet-food/283-e4dd786d-8c18-42a2-92ee-7d4225c00aca

Quentin. (2022). Eclo raises €4.7M to create a high-tech circular organic mushroom substrate factory. Eclo | Mushrooms & Microgreens Grown in Brussels. Website: https://eclo.farm/2022/07/eclo-raises-e4-7m-to-create-a-high-tech-circular-organic-mushroom-substrate-factory/

O’Connell, T. (2019). Nelson fisherman making a difference with beer-related plastic alternative. Stuff. Website: https://www.stuff.co.nz/nelson-mail/news/110338378/nelson-fisherman-making-a-difference-with-beerrelated-plastic-alternative

Krishania, M., Sindhu, R., Binod, P., Ahluwalia, V., Kumar, V., Sangwan, R. S., & Pandey, A. (2018). Design of bioreactors in solid-state fermentation. In Current Developments in Biotechnology and Bioengineering.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. TJL performed the literature search and wrote this article. ZWL and SHM reviewed and edited the manuscript. All the authors read and approved the manuscript.

Corresponding author

Ethics declarations

Ethics Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Consent to Participate

This article does not contain any studies with human participants or animals performed by any of the authors. Therefore there is no consent to participate needed.

Consent for Publication

This article does not contain any studies with human participants or animals performed by any of the authors. Therefore, there is no consent to publish needed.

Competing Interests

All authors certify that they have no affiliations with or involvement in any organization or entity with any financial interest or non-financial interest in the subject matter or materials discussed in this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lock, T.J., Mah, S.H. & Lai, Z.W. Versatile Applications of Brewer’s Spent Grain: Solid-State Fermentation and Nutritional Added Value. Appl Biochem Biotechnol (2023). https://doi.org/10.1007/s12010-023-04769-3

Accepted:

Published:

DOI: https://doi.org/10.1007/s12010-023-04769-3