Abstract

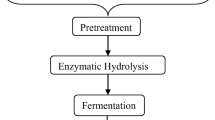

The screening and evaluation of different waste lignocellulosic biomasses to meet the ever-increasing energy demand, from the widely available waste lignocellulosic biomasses evaluated. For the current study, peanut shell biomass is considered for energy procreation. However, the energy content of biomass is still lesser as compared to conventional fossil fuels like coal and petroleum. The dilute acid pretreatment has been proven to improve the energy content of the lignocellulosic biomasses to a significant extent. Various pretreatment process parameters have been reported to have different degrees of impact on the betterment of energy procreation. Among various types of pretreatments, dilute acid pretreatment holds notable cognizance. Accordingly, the current manuscript is to evaluate the impact of various pretreatment process parameters (time, temperature, acid concentration, mass:liquor ratio, and particle size which were defined through an exhaustive literature search) for improving the energy recovery potential. The obtained results indicated notable changes in the devolatilization characteristics of the biomass as a result of pretreatment, thereby resulting in the upgradation of the fuel properties. A sustainability investigation has been carried out to point out the efficacy of the optimized pretreatment of biomass in terms of environmental sustainability and was also compared with the raw variant (untreated form of biomass). The proposed scheme of study will definitely be beneficial toward the mitigation of the energy crisis in the state of Jharkhand.

Similar content being viewed by others

Availability of Data and Materials

Not applicable.

Abbreviations

- ANOVA:

-

Analysis of variance

- AP:

-

Acidification potential

- BBD:

-

Box-Behnken designing

- DGT:

-

Derivative thermogravimetry

- EP:

-

Eutrophication potential

- FTIR:

-

Fourier transform infrared spectroscopy

- GWP:

-

Global warming potential

- HHV:

-

Higher heating value

- HTP:

-

Human toxicity potential

- ICAR:

-

Indian Council for Agricultural Research

- ISO:

-

International Organization for Standardization

- LCA:

-

Life cycle assessment

- LCI:

-

Life cycle inventory

- MAETP:

-

Marine aquatic eco-toxicity potential

- MLR:

-

Mass:liquor ratio

- MT:

-

Million tons

- ODP:

-

Ozone depletion potential

- OFAT:

-

One-factor-at-a-time

- PCA:

-

Principal component analysis

- PCs:

-

Principal components

- RSM:

-

Response surface methodology

- SEM:

-

Scanning electron microscopy

- TETP:

-

Terrestrial eco-toxicity potential

- XRD:

-

X-ray diffraction

References

Bertioli, D. J., Seijo, G., Freitas, F. O., Valls, J. F., Leal Bertioli, S. C., & Moretzsohn, M. C. (2011). An overview of peanut and its wild relatives. Plant Genetic Resources, 9(01), 134–149.

Radhakrishnan, R., Pae, S. B., Lee, B. K., & Baek, I. Y. (2013). Evaluation of luteolin from shells of Korean peanut cultivars for industrial utilization. African Journal of Biotechnology, 12(28), 4477–4480.

Wee, J. H., Moon, J. H., Eun, J. B., Chung, J. H., Kim, Y. G., & Park, K. H. (2007). Isolation and identification of antioxidants from peanut shells and the relationship between structure and antioxidant activity. Food Science and Biotechnology, 16(1), 116–122.

Wilson, K., Yang, H., Seo, C. W., & Marshall, W. E. (2006). Select metal adsorption by activated carbon made from peanut shells. Bioresource Technology., 97(18), 2266–2270.

Shi, Z., Ma, A., Chen, Y., Zhang, M., Zhang, Y., Zhou, Na., Fan, S., & Wang, Yi. (2023). The Removal of tetracycline from aqueous solutions using peanut shell biochars prepared at different pyrolysis temperatures. Sustainability., 15(1), 874.

Creating wealth from Agricultural Waste. (2020). Indian Council for Agricultural Research, New Delhi. URL: Creating-Wealth-From-Agricultural-Waste.pdf (icar.org.in).

Sattar, M. S., Shakoor, M. B., Ali, S., Rizwan, M., Niazi, N. K., & Jilani, A. (2019). Comparative efficiency of peanut shell and peanut shell biochar for removal of arsenic from water. Environmental Science and Pollution Research, 26(18), 18624–18635.

Bandopadhyay, R., Banerjee, C., Sarkar, A., & Gupta, P. (2013). Isolation of indigenous microalgae and biomass collection for biofuel production. Recent Advances in Bioenergy Research, 2, 304–314.

Gupta, Pratibha, Banerjee, Aparna, Castillo, Alexis, & Bandopadhyay, Rajib. (2021). Novel phenolic compound from Southern Ocean microalgae Chlorella sp. PR-1 and its antibacterial activity. Gayana Botanica., 78(1), 29–37.

Banerjee, C., Gupta, P., Mishra, S., Sen, G., Shukla, P., Bandopadhyay, R. (2012). Study of polyacrylamide grafted starch based algal flocculation towards applications in algal biomass harvesting. International Journal of Biological Macromolecules, 51(4), 456–61.

Gupta, P., Sinhab, D., Bandopadhyaya, R.(2014). Isolation and screening of marine microalgae Chlorella sp. _pr1 for anticancer activity. International Journal of Pharmacy and Pharmaceutical Sciences, 6, 517–519.

Gautam, S. P., Bundela, P. S., Pandey, A. K., Khan, J., Awasthi, M. K., & Sarsaiya, S. (2011). Optimization for the production of cellulase enzyme from municipal solid waste residue by two novel cellulolytic fungi. Biotechnology Research International, 810425.

Kumari, U., & Gupta, P. (2023). Screening and characterization of waste lignocellulosic biomass as a potential substrate for energy recovery. Environmental Quality Management. https://doi.org/10.1002/tqem.22083

Kumar, D., & Murthy, G. S. (2011). Impact of pretreatment and downstream processing technologies on economics and energy in cellulosic ethanol production. Biotechnology for Biofuels, 4(1), 1–19.

Edenhofer, O., Pichs-Madruga, R., Sokona, Y., Seyboth, K., Kadner, S., Zwickel, T., & Matschoss, P. (Eds.). (2011). Renewable energy sources and climate change mitigation: Special report of the intergovernmental panel on climate change. Cambridge University Press.

Zhivin, O., Dassa, B., Moraïs, S., Utturkar, S. M., Brown, S. D., Henrissat, B., & Bayer, E. A. (2017). Unique organization and unprecedented diversity of the Bacteroides (Pseudobacteroides) cellulosolvens cellulosome system. Biotechnology for Biofuels, 10(1), 1–19.

Shen, H., Poovaiah, C. R., Ziebell, A., Tschaplinski, T. J., Pattathil, S., Gjersing, E., & Dixon, R. A. (2013). Enhanced characteristics of genetically modified switchgrass (Panicum virgatum L.) for high biofuel production. Biotechnology for Biofuels, 6(1), 1–15.

Solarte-Toro, J. C., Romero-García, J. M., Martínez-Patiño, J. C., Ruiz-Ramos, E., Castro-Galiano, E., & Cardona-Alzate, C. A. (2019). Acid pretreatment of lignocellulosic biomass for energy vectors production: A review focused on operational conditions and techno-economic assessment for bioethanol production. Renewable and Sustainable Energy Reviews. https://doi.org/10.1016/j.rser.2019.02.024

Roesijadi, G., Cop**, A. E., Huesemann, M. H., Forster, J., & Benemann, J. R. (2008). Techno-economic feasibility analysis of offshore seaweed farming for bioenergy and biobased products. Battelle Pacific Northwest Division Report Number PNWD-3931, 1e115.

Bezerra, M. A., Santelli, R. E., Oliveira, E. P., Villar, L. S., & Escaleira, L. A. (2008). Response surface methodology (RSM) as a tool for optimization in analytical chemistry. Talanta, 76(5), 965–977.

Khuri, A.I., Mukhopadhyay, S. (2010). Response surface methodology. WIREs Computational Statistics, 2(2), 128–149.

Kumagai, S., Matsuno, R., Grause, G., Kameda, T., & Yoshioka, T. (2015). Enhancement of bio-oil production via pyrolysis of wood biomass by pretreatment with H2SO4. Bioresource technology, 178, 76–82.

Rodrigues, R. C. L. B., Rodrigues, B. G., Martinez, E. A., Palladino d, F., Canettieri, E. V., Wisniewski Jr, A., & Rodrigues Jr, D. (2022). Comprehensive approach of methods for microstructural analysis and analytical tools in lignocellulosic biomass assessment – A review. Bioresource Technology, 348, 126627.

Bouten, L., Van Handel, R., & James, M. R. (2007). An introduction to quantum filtering. SIAM Journal on Control and Optimization, 46(6), 2199–2241.

Akogun, O. A., & Waheed, M. A. (2019). Property upgrades of some raw Nigerian biomass through torrefaction pre-treatment-A review. Journal of Physics: Conference Series, 1378(3), 032026. IOP Publishing.

López-Arenas, T., Rathi, P., Ramírez-Jiménez, E., & Sales-Cruz, M. (2010). Factors affecting the acid pretreatment of lignocellulosic biomass: Batch and continuous process. Computer Aided Chemical Engineering, 28, 979–984. Elsevier.

Kim, S. B., & Lee, Y. Y. (2002). Diffusion of sulfuric acid within lignocellulosic biomass particles and its impact on dilute-acid pretreatment. Bioresource Technology, 83(2), 165–171.

Kumar, R., Strezov, V., Weldekidan, H., He, J., Singh, S., Kan, T., & Dastjerdi, B. (2020). Lignocellulose biomass pyrolysis for bio-oil production: A review of biomass pre-treatment methods for production of drop-in fuels. Renewable and Sustainable Energy Reviews, 123, 109763.

Singh, S., Cheng, G., Sathitsuksanoh, N., Wu, D., Varanasi, P., George, A., & Simmons, B. A. (2015). Comparison of different biomass pretreatment techniques and their impact on chemistry and structure. Frontiers in Energy Research, 2, 62.

Qi, B., Chen, X., Shen, F., Su, Y., & Wan, Y. (2009). Optimization of enzymatic hydrolysis of wheat straw pretreated by alkaline peroxide using response surface methodology. Industrial & Engineering Chemistry Research, 48(15), 7346–7353.

Rajput, A. P., & Butani, S. B. (2019). Resveratrol anchored nanostructured lipid carrier loaded in situ gel via nasal route: Formulation, optimization and in vivo characterization. Journal of Drug Delivery Science and Technology, 51, 214–223. https://doi.org/10.1016/j.jddst.2019.01.040

Sherpa, K.C., Ghangrekar, M.M., Banerjee, R. Optimization of saccharification of enzymatically pretreated sugarcane tops by response surface methodology for ethanol production. Biofuels. https://doi.org/10.1080/17597269.2017.1409058

Garai, D., & Kumar, V. (2013). A Box-Behnken design approach for the production of xylanase by Aspergillus candidus under solid state fermentation and its application in saccharification of agro residues and Parthenium hysterophorus L. Industrial Crops and Products, 44, 352–363.

Lahiri, D., Nag, M., Sarkar, T., Dutta, B., & Ray, R. R. (2021). Antibiofilm activity of α-amylase from Bacillus subtilis and prediction of the optimized conditions for biofilm removal by response surface methodology (rsm) and artificial neural network (ANN). Applied Biochemistry and Biotechnology, 193(6), 1853–1872.

Sultana, A., Novera, T. M., Islam, M. A., Limon, S. H., & Islam, M. A. (2022). Multi-response optimization for the production of Albizia saman bark hydrochar through hydrothermal carbonization: Characterization and pyrolysis kinetic study. Biomass Conversion and Biorefinery, 12, 5783–5797.

Ballice, L., Sert, M., Sağlam, M., & Yüksel, M. (2020). Determination of pyrolysis kinetics of cellulose and lignin fractions isolated from selected Turkish biomasses. Arabian Journal for Science and Engineering, 45, 7429–7444.

Zhang, Y., Li, Y., Zhang, Y., & Jiang, T. (2018). Underwater anchor-AUV localization geometries with an isogradient sound speed profile: A CRLB-based optimality analysis. IEEE Transactions on Wireless Communications, 17(12), 8228–8238.

Shehzad, M., Asghar, A., Ramzan, N., Aslam, U., & Bello, M. M. (2020). Impacts of non-oxidative torrefaction conditions on the fuel properties of indigenous biomass (bagasse). Waste Management & Research, 38(11), 1284–1294.

Sukiran, M. A., Abnisa, F., Syafiie, S., Daud, W. M. A. W., Nasrin, A. B., Aziz, A. A., & Loh, S. K. (2020). Experimental and modelling study of the torrefaction of empty fruit bunches as a potential fuel for palm oil mill boilers. Biomass and bioenergy, 136, 105530.

Wyn, H. K., Konarova, M., Beltramini, J., Perkins, G., & Yermán, L. (2020). Self-sustaining smouldering combustion of waste: A review on applications, key parameters and potential resource recovery. Fuel processing technology, 205, 106425.

Huang, D., Li, R., Xu, P., Li, T., Deng, R., Chen, S., & Zhang, Q. (2020). The cornerstone of realizing lignin value-addition: Exploiting the native structure and properties of lignin by extraction methods. Chemical Engineering Journal, 402, 126237. https://doi.org/10.1016/j.cej.2020.126237

Lupoi, J. S., Singh, S., Parthasarathi, R., Simmons, B. A., & Henry, R. J. (2015). Recent innovations in analytical methods for the qualitative and quantitative assessment of lignin. Renewable and Sustainable Energy Reviews, 49, 871–906.

Naik, S., Goud, V., Rout, P., Jacobson, A., & Dalai, A. (2010). Characterization of Canadian biomass for alternative renewable biofuel. Renewable Energy, 35, 1624–1631.

Mothe, C., & Miranda, I. (2009). Characterization of sugarcane and coconut fibers by thermal analysis and FTIR. Journal of Thermal Analysis and Calorimetry, 97, 661–665. https://doi.org/10.1007/s10973-009-0346-3

Akhtar, N., Gupta, K., Goyal, D., & Goyal, A. (2016). Recent advances in pretreatment technologies for efficient hydrolysis of lignocellulosic biomass. Environmental Progress & Sustainable Energy, 35(2), 489–511.

Tian, D., Guo, Y., Hu, J., Yang, G., Zhang, J., Luo, L., & Shen, F. (2020). Acidic deep eutectic solvents pretreatment for selective lignocellulosic biomass fractionation with enhanced cellulose reactivity. International Journal of Biological Macromolecules, 142, 288–297. https://doi.org/10.1016/j.ijbiomac.2019.09.100

Singh, Y. D., Mahanta, P., & Bora, U. (2017). Comprehensive characterization of lignocellulosic biomass through proximate, ultimate and compositional analysis for bioenergy production. Renewable Energy, 103, 490–500.

Siddhartha, P., Anil, C., Prasad, D. B., Bryan, R. N., Tanmay, S., Salwa, S., Hisham, A. E., Sabariah, B. A. M. T., Paramananda, J., Kishore, M. Y., & Diptikanta, A. (2020). Structural Characterization and Antioxidant Potential of Chitosan by γ-Irradiation from the Carapace of Horseshoe Crab. Polymers, 12(10), 2361.

Li, X., Jie, Lu., Zhao, J., & Yinbo, Qu. (2014). Characteristics of corn stover pretreated with liquid hot water and fed-batch semi-simultaneous saccharification and fermentation for bioethanol production. PLoS ONE, 9, 1–11.

Joglekar, S. N., Tandulje, A. P., Mandavgane, S. A., & Kulkarni, B. D. (2019). Environmental impact study of bagasse valorization routes. Waste and Biomass Valorization, 10(7), 2067–2078.

ISO 14040 (1997). ISO 14040: Environmental management: Life cycle assessment—Principles and framework. ISO, Geneva.

Nie, Z., Korre, A., & Durucan, S. (2011). Life cycle modelling and comparative assessment of the environmental impacts of oxy-fuel and post-combustion CO2 capture, transport and injection processes. Energy Procedia, 4, 2510–2517.

Cao, G., Zhang, X., Wang, Y., & Zheng, F. (2008). Estimation of emissions from field burning of crop straw in China. Chinese Science Bulletin, 53(5), 784–790.

Romasanta, R. R., Sander, B. O., Gaihre, Y. K., Alberto, M. C., Gummert, M., Quilty, J., … Wassmann, R. (2017). How does burning of rice straw affect CH 4 and N 2 O emissions? A comparative experiment of different on-field straw management practices. Agriculture, Ecosystems & Environment, 239, 143–153.

Shafie, S. M., Masjuki, H. H., & Mahlia, T. M. I. (2014). Life cycle assessment of rice straw-based power generation in Malaysia. Energy, 70, 401–410.

Gadde, B., Bonnet, S., Menke, C., & Garivait, S. (2009). Air pollutant emissions from rice straw open field burning in India, Thailand and the Philippines. Environmental Pollution, 157(5), 1554–1558.

Zhang, H., Ye, X., Cheng, T., Chen, J., Yang, X., Wang, L., & Zhang, R. (2008). A laboratory study of agricultural crop residue combustion in China: Emission factors and emission inventory. Atmospheric Environment, 42(36), 8432–8441.

Mara, U.T., Syuhaida, S., Mohamed, B. (2015). Life cycle assessment of carbon dioxide emissions in gasoline process in Malaysia. https://doi.org/10.13140/RG.2.1.3560.3361

Janghathaikul, D., & Gheewala, S. H. (2004). Bagasse-A sustainable energy resource from sugar mills. In The Joint International Conference on “Sustainable Energy and Environment (SEE) (pp. 1–3).

Milačič, R., Ščančar, J., Murko, S., Kocman, D., & Horvat, M. (2010). A complex investigation of the extent of pollution in sediments of the Sava River. Part 1. Selected elements. Environmental Monitoring and Assessment, 163, 263–275.

Von Blottnitz, H., & Curran, M. A. (2007). A review of assessments conducted on bio-ethanol as a transportation fuel from a net energy, greenhouse gas, and environmental life cycle perspective. Journal of Cleaner Production, 15(7), 607–619.

Ravishankara, A. R., Daniel, J. S., & Portmann, R. W. (2009). Nitrous oxide (N2O): The dominant ozone-depleting substance emitted in the 21st century. Science, 326(5949), 123–125.

Acknowledgements

The authors acknowledge the Departments of Biotechnology and Research Cell of Radha Govind University, Lalki Ghati, Ramgarh, Jharkhand, for providing the research facility.

Author information

Authors and Affiliations

Contributions

All the authors have equal contributions to the reported study.

Corresponding author

Ethics declarations

Ethical Approval

Not applicable.

Consent to Participation

All the authors had their consent for participation in the reported study.

Consent for Publication

All the authors had their consent for the publication of the reported study.

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumari, U., Gupta, P. Evaluation and Optimization of the Different Process Parameters of Mild Acid Pretreatment of Waste Lignocellulosic Biomass for Enhanced Energy Procreation. Appl Biochem Biotechnol 196, 3765–3785 (2024). https://doi.org/10.1007/s12010-023-04737-x

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-023-04737-x