Abstract

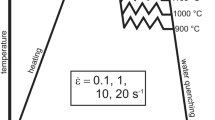

Present study is aimed at develo** Hall–Petch and Hollomon models for 2219Al alloys microalloyed with varying Cd contents (up to 0.1 wt%), under different thermo-mechanical treatments. Alloys were cast and subjected to standard sequential thermo-mechanical processes of rolling and age-hardening treatments. Average grain sizes were microscopically determined, and uniaxial tensile tests were performed to generate flow curves and evaluate yield strength of the alloys. Average grain diameter of 2219Al base alloy decreased (by 20.6%), while yield strength concomitantly increased (by 24.5%), with increasing Cd addition up to 0.061 wt%. Rolled peak-aged alloys recorded highest average grain refinement and increase in yield strength by 13.7% and 21.1% respectively, among all thermo-mechanical treatments. Effect of grain size on mechanical strength was analytically modeled through Hall–Petch equation, using Weighted Least Square methodology. Hall–Petch parameters of the alloys were evaluated for the first time, considering separate processing conditions. Yield strength values computed from Hall–Petch models, were successfully compared with experimental results with fairly good accuracy, to validate estimated Hall–Petch parameters. Hollomon equation was further used to mathematically model the flow curves. Strength coefficient (K) and strain hardening exponent (n) values were evaluated, first time for the present alloys, under different processing conditions. Trace contents of Cd and processing parameters exhibited to have significant potential to refine grain structure and enhance mechanical strength of 2219Al alloy. Present investigation provides a structure–property correlation to validate the manufacturing feasibility and prospective applications of these alloys, subjected under different thermo-mechanical treatments.

Similar content being viewed by others

References

Ron, C., Alcan, C., Banbury, C.: Aluminum: physical properties, characteristics and alloys. Euro. Alum. Ass. 1–60 (1994).

Elagin, V.I.: Ways of develo** high-strength and high-temperature structural aluminium alloys in the 21st century. Metal Sci. Heat Treat. 49, 427–434 (2007)

Rambabu, P., Prasad, N.E., Kutumbarao, V.V., Wanhill, R.J.H.: Aluminium alloys for aerospace applications. Aerosp. Mater. Mater. Technol. 1, 29–52 (2017)

Campbell, F.C.: Light Weight Materials, 1st edn. ASM International, Materials Park, Ohio (2012)

Starke, E.A., Staley, J.T.: Application of modern aluminum alloys to aircraft. Prog. Aerosp. Sci. 32, 131–172 (1996)

Prabhu, T.R.: Hot forging design and evaluation of the aircraft landing gear barrel Al–Cu alloy structure through simulations and experiments. J. Mater. Eng. Perform. 25(4), 1257–1268 (2016)

Prabhu, T.R.: Mechanical properties, microstructure and fracture surface characterization of thixoforming processed Al–Cu–Mg alloy. Arch. Civ. Mech. Eng. 16(3), 335–343 (2016)

Rao, P.S., Sivadasan, K.G., Balasubramanian, P.K.: Structure–property correlation on AA2219 aluminium alloy weldments. Bull. Mater. Sci. 19(3), 549–557 (1996)

Gogoi, S., Banerjee, S., Bhowmick, S.: Modelling precipitation kinetics and investigating age-hardening behaviour of 2219Al alloys microalloyed with Cd. J. Therm. Anal. Calorim. 147, 12437–12453 (2022)

Banerjee, S., Robi, P.S., Srinivasan, A., Lakavath, P.K.: Effect of trace additions of Sn on microstructure and mechanical properties of Al-Cu-Mg alloys. Mater. Des. 31, 4007–4015 (2010)

Gogoi, S., Banerjee, S., Kirtania, S., Kashyap, S., Bhadra, R: Computational modelling of tensile flow parameters for 2219Al alloys microalloyed with Cd. Int. J. Interact. Des. Manuf. 1–10 (2022).

Banerjee, S., Gogoi, S.: Optimizing the peak-ageing conditions for microalloyed 2219Al alloys. In: Arockiarajan, A., Duraiselvam, M., Raju, R., Reddy, N.S., Satyanarayana, K. (eds.) Recent Advances in Materials Processing and Characterization: Lecture Notes in Mechanical Engineering, pp. 43–53. Springer, Singapore (2023)

Gogoi, S., Nath, B., Konwar, B., Bora, A., Banerjee, S., Kashyap, S., Kirtania, S.: Investigating machinability of microalloyed Al–Cu alloys by simulation of cutting force. In: Arockiarajan, A., Duraiselvam, M., Raju, R., Reddy, N.S., Satyanarayana, K. (eds.) Recent Advances in Materials Processing and Characterization: Lecture Notes in Mechanical Engineering, pp. 275–286. Springer, Singapore (2023)

Gogoi, S., Kumar, D., Banerjee, S., Kirtania, S., Kashyap, S.: Tribological characterization of microalloyed Al–Cu alloys by artificial neural network modeling. In: Arockiarajan, A., Duraiselvam, M., Raju, R., Reddy, N.S., Satyanarayana, K. (eds.) Recent Advances in Materials Processing and Characterization: Lecture Notes in Mechanical Engineering, pp. 83–92. Springer, Singapore (2023)

Banerjee, S., Bhadra, R., Gogoi, S., Dutta, R.S.: Investigating weldability in microalloyed Al alloys. In: Biswal, B., Sarkar, B., Mahanta, P. (eds.) Advances in Mechanical Engineering: Lecture Notes in Mechanical Engineering, pp. 271–279. Springer, Singapore (2020)

Banerjee, S., Robi, P.S., Srinivasan, A., Gogoi, S., Bhowmick, S.: Effect of trace additions of Sn on precipitation kinetics and microstructural phases of Al–Cu–Mg alloys. React. Kinet. Mech. Catal. 135, 1853–1874 (2022)

Hornbogen, E.: Hundred years of precipitation hardening. J. Light Metal 1, 127–132 (2001)

Sercombe, T.B., Schaffer, G.B.: On the use of trace additions of Sn to enhance sintered 2xxx series Al powder alloys. Mater. Sci. Eng. A. 268, 32–39 (1999)

Vietz, J.T., Polmear, I.J.: The influence of small additions of silver on the ageing of aluminium alloys. J. Miner. Metal Mater. Soc. 94(12), 410–418 (1966)

Yan, L.X., Lin, P.Q., Ge, L.C., Bin, H.Y., Bin, L.W., Jie, L.W.: Microstructure and mechanical properties of Al–Cu–Mg–Mn–Zr alloy with trace amounts of Ag. Mater. Sci. Eng. A. 525, 128–132 (2009)

Callister, W.D.: Material Science and Engineering: An Introduction. John Wiley & Sons Inc, Utah (1997)

Andrianopoulos, P., Theocaris, P.S.: The Griffith-Orowan fracture theory revisited: the T-Criterion. I. J. Mech. Sci. 27(11–12), 793–801 (1985)

Miao, W.F., Laughlin, D.E.: Effects of Cu content and presaging on precipitation characteristics in aluminium alloy 6022. Metall. Mater. Trans. A 31(A), 361–371 (2000)

Miao, L.X., Lin, P.Q., Ge, L.C., Bin, H.Y., Bin, L.W., Jie, L.W.: Microstructure and mechanical properties of Al–Cu–Mg–Mn–Zr alloy with trace amounts of Ag. Mater. Sci. Eng. A. 525, 128–132 (2009)

Venkatasubramaniana, G., Mideena, A.S., Jhab, A.K.: Microstructural characterisation and corrosion behaviour of top surface of tig welded 2219–t87 aluminium alloy. I. J. Eng. Sci. Tech. 5, 624–629 (2013)

Metals Handbook Properties and Selection: Non-Ferrous Alloys and Special Purpose Materials. ASM International, Materials Park, OH (1990)

Mandal, P.K., Robi, P.S.: Influence of microalloying with silver on microstructure and mechanical properties of Al–Cu alloy. Matal Sci. Eng. A. 722, 99–111 (2018)

Maksimovic, V., Slavicazec, V., Jovanovic, M.T.: The effect of microalloying with silicon and germanium on microstructure and hardness of a commercial aluminium alloy. J. Serb. Chem. Soc. 68(11), 893–901 (2003)

Raju, P.N., Rao, K.S., Reddy, G.M., Kamaraj, M., Rao, K.P.: Microstructure and high temperature stability of age-hardenable AA2219 aluminium alloy modified by Sc, Mg and Zr additions. Mater. Sci. Eng. A. 464, 192–201 (2007)

Vietz, J.T., Polmear, I.J.: The influence of small additions of silver on the ageing of aluminium alloys. J. I. Met. 94(12), 410–418 (1966)

Zolotorevsky, V.S., Belov, N.A., Glazoff, M.V.: Casting Aluminium Alloys. Elsevier Science (2007)

Thangaraju, S.: On the estimation of true Hall Petch constants and their role on the superposition law exponent in Al alloys. Adv. Eng. Mater. 10, 892–897 (2011)

Abrams, H.: Grain size measurement by the intercept method. Metallography 4, 59–78 (1971)

Kaibyshev, R.I., Kazakulov, D., Gromov, F., Muskin, D.R., Neih, L.T.G.: Superplasticity in 2219 Al-Alloys. Script. Matter. 44, 2411–2417 (2001)

Dossett, J.L., George, E.: Totten ASM Handbook, Heat treatments. ASM International, Materials Park, OH (1991)

Dieter, G.E.: Engineering Materials. Mechanical Metallurgy. John Wiley & Sons, New York (1988)

Schneider, M.: Effect of temperature and texture on Hall–Petch strengthening by grain and annealing twin boundaries in the Mn–Fe–Ni medium-entropy Alloy. Metals 9, 84–101 (2015)

George, F.: Grain size measurement methods: a review and comparison. Micro. Soc. Am. 19(S2), 1760–1761 (2013)

Mohamed, A.M.A., Samuel, F.H., Samuel, A.M., Doty, H.W., Valtierra, S.: Influence of Tin addition on the microstructure and mechanical properties of Al–Si–Cu–Mg and Al–Si–Mg casting alloys. Metall. Mater. Trans. A. 39, 490–501 (2008)

Silcock, J.M., Flower, H.M.: Comments on a comparison of early and recent work on the effect of trace additions of Cd, In, or Sn on the nucleation and growth of θ` in Al–Cu alloys. Scr. Mater. 46, 389–394 (2002)

Li, Y., Bushby, A.J., Dunstan, D.J.: The Hall–Petch effect as a manifestation of the general size effect. Proc. Math. Phys. Eng. Sci. (2016). https://doi.org/10.1098/rspa.2015.0890

Kusakin, P., Belyakov, A., Kaibyshev, R., Molodov, D.: Modeling the effect of deformation on strength of a Fe–23Mn–0.3C–1.5Al TWIP steel. Mat. Sci. Eng. 63, 1–8 (2014)

Hollomon, J.R.: Tensile deformation. Trans. AIME. 162, 268–277 (1945)

Davis, J.R.: Alloying: Understanding the basics aluminum and aluminum alloys. ASM Int. 351–416 (1998).

Acknowledgements

The authors are thankful to the Department of Mechanical Engineering, Tezpur University, for the useful assistance in various experimental procedures. The authors acknowledge the help received from the Department of Mechanical Engineering, NIT Silchar, during conduction of tensile tests.

Funding

This research work was supported by Department of Science and Technology (DST) [Grant no: SERC/ET-0403/2012, Year: 2013].

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by all the authors. The first draft of the manuscript was written by Sanjib Gogoi and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gogoi, S., Siddiqui, H.R., Banerjee, S. et al. Hall–Petch and Hollomon modeling for microalloyed 2219Al alloys under different thermo-mechanical treatments. Int J Interact Des Manuf (2023). https://doi.org/10.1007/s12008-023-01313-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-023-01313-9