Abstract

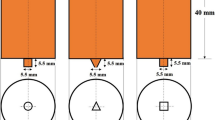

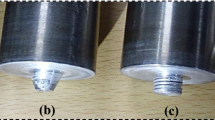

Producing defect-free and high-quality welds are still challenging by the friction stir welding process. In this paper, ZrO2 nanoparticles of 20 nm average size were used in the weld area of Aluminium 8011 alloy. Three different types of tool profiles semi-circular, plus tool and trapezium profiles were used for better material mixing and improved joint strength. All of the experiments were performed with rotational speeds of 1800, 1120, and 560 RPM, and a constant welding speed of 25 mm/min. It was observed that there is no significant effect of the ZrO2 addition in the weld area. On the other hand, tool profile plays a great role in increasing tensile strength. The maximum tensile strength of 116.70 MPa was obtained with the semi-circular tool at 1800 RPM and 25 mm/min welding speed because of the improved material mixing and defect-free joint.

Similar content being viewed by others

References

Bhushan, R.K., Sharma, D.: Investigation of mechanical properties and surface roughness of friction stir welded AA6061-T651. Int. J. Mech. Mater. Eng. 15, 7 (2020). https://doi.org/10.1186/s40712-020-00119-x

Attah, B.I., Lawal, S.A., Akinlabi, E.T., Bala, K.C.: Evaluation of mechanical properties of dissimilar aluminium alloys during friction stir welding using tapered tool. Cogent Eng. 8(1), 1909520 (2021). https://doi.org/10.1080/23311916.2021.1909520

Jayaprakash, S., Siva Chandran, S., Sathish, T., Gugulothu, B., Ramesh, R., Sudhakar, M., Subbiah, R.: Effect of tool profile influence in dissimilar friction stir welding of aluminium alloys (AA5083 and AA7068). Adv. Mater. Sci. Eng. 2021, 1–7 (2021). https://doi.org/10.1155/2021/7387296

Abdollahzadeh, A., Bagheri, B., Abbasi, M., et al.: Mechanical, wear and corrosion behaviors of AZ91/SiC composite layer fabricated by friction stir vibration processing. Surf. Topogr. Metrol. Prop. 9(3), 035038 (2021)

Chang, C.I., Wang, Y.N., Pei, H.R., Lee, C.J.: Microstructure and mechanical properties of nano-ZrO2 and nano-SiO2 particulate reinforced AZ31-Mg based composites fabricated by friction stir processing. Key Eng. Mater. 351, 114–119 (2007)

Sabbar, H.M., Leman, Z., Shamsudin, S.B., Aiza Tahir, S.M., Jaafar, C.N., Hanim, M.A.A., Ismsrrubie, Z.N., Al-Alimi, S.: AA7075-ZrO2 nanocomposites produced by the consecutive solid-state process: a review of characterisation and potential applications. Metals 11, 805 (2021). https://doi.org/10.3390/met11050805

Jamali, A., Mirsalehi, S.E.: Production of AA7075/ZrO2 nanocomposite using friction stir processing: metallurgical structure, mechanical properties and wear behavior. CIRP J. Manuf. Sci. Technol. 37, 55–69 (2022). https://doi.org/10.1016/j.cirpj.2021.12.008

Msomi, V., Mbana, N.: Mechanical properties of friction stir welded AA1050-H14 and AA5083-H111 joint: sampling aspect. Metals 10(2), 214 (2020)

Suvarna Raju, L., Kumar, A.: Influence of Al2O3 particles on the microstructure and mechanical properties of copper surface composites fabricated by friction stir processing. Def. Technol. 2014, 375–383 (2014)

Oliveira, J.P., Duarte, J.F., Inácio, P., Schell, N., Miranda, R.M., Santos, T.G.: Production of Al/NiTi composites by friction stir welding assisted by electrical current. Mat. Des. 113, 311–318 (2017)

Rao, A.N., Naik, L.S., Srinivas, C.: Evaluation and impacts of tool profile and rotational speed on mechanical properties of friction stir welded copper 2200 alloy. Mater. Today: Proc. 4(2), 1225–1229 (2017)

Chang, C.I., Wang, Y.N., Pei, H.R., Lee, C.J., Du, X.H., Huang, J.C.: Microstructure and mechanical properties of nano-ZrO2 and nano-SiO2 particulate reinforced AZ31-Mg based composites fabricated by friction stir processing. Key Eng. Mater. 351, 114–119 (2007)

Ahmadifard, S., Heidarpour, A., Kazemi, S.: The effects of pass number and nano-size ZrO2 powder on the mechanical, microstructure and wear behavior in friction stir welding of the Al-5083. Modares Mech. Eng. 18(3), 219–227 (2018)

Sameer, M.D., Birru, A.K.: Mechanical and metallurgical properties of friction stir welded dissimilar joints of AZ91 magnesium alloy and AA 6082–T6 aluminium alloy. J. Magn. Alloys 7(2), 264–271 (2019)

Srinivas Naik, L., Jush Kumar, S., Murahari, K.: Tool design and analysis of friction stir welding process by using FEA. Int. JMER 6(9), 7–16 (2016)

Khodabakhshi, F., Haghshenas, M., Chen, J., Shalchi Amirkhiz, B., Li, J., Gerlich, A.P.: Bonding mechanism and interface characterization during dissimilar friction stir welding of an aluminium/polymer bi- material joint’. Sci. Technol. Weld. Join. 20, 1–9 (2016)

Li, P., Chen, S., Dong, H., Ji, H., Li, Y., Guo, X., Yang, G., Zhang, X., Han, X.: Interfacial microstructure and mechanical properties of dissimilar aluminium/steel joint fabricated via refilled friction stir spot welding. J. Man. Proc. 49, 385–396 (2020)

Li, G.H., Zhou, L., Luo, S.F., Du, Z.Y., Feng, J.C., Meng, F.X.: Microstructure and mechanical properties of self-reacting friction stir welded AA2219-T87 aluminium alloy. Sci. Technol. Weld. Join. 25, 142–149 (2020)

El-Morsy, M., Ghanem, H.: Bahaitham, Effect of friction stir welding parameters on the microstructure and mechanical properties of AA2024-T4 aluminum alloy. Eng. Technol. Appl. Sci. Res. 8, 2493–2498 (2018)

Bagheri, B., Abdollahzadeh, A., Sharifi, F., et al.: The role of vibration and pass number on microstructure and mechanical properties of AZ91/SiC composite layer during friction stir processing. Proc. Inst. Mech. Eng. Part C: J. Mech. Eng. Sci. 236, 2312–2326 (2022)

Shafiei-Zarghani, A., Kashani-Bozorg, S.F., Zarei-Hanzaki, A.: Microstructures and mechanical properties of Al/Al2O3 surface nano-composite layer produced by friction stir processing. Mater. Sci. Eng. A 500, 84–91 (2009)

Fattah-alhosseini, A., Naseri, M., Gholami, D., Imantalab, O., Attarzadeh, F.R., Keshavarz, M.K.: Microstructure and corrosion characterization of the nugget region in dissimilar friction-stir-welded AA5083 and AA1050. J. Mater. Sci. 54, 777–790 (2019)

Patel, V., Li, W., Wang, G., Wang, F., Vairis, A., Niu, P.: Friction stir welding of dissimilar aluminum alloy combinations: state-of-the-art. Metals 9, 270 (2019)

Ubaid, M., Bajaj, D., Mukhopadhyay, A.K., Siddiquee, A.N.: Friction stir welding of thick AA2519 alloy: defect elimination, mechanical and micro-structural characterization. Metals Mater. Int. 26, 1841–1860 (2020)

Naik, L.S., Hadya, B.: Evaluation and impacts on mechanical behavior of friction stir welded copper 2200 alloy. Recent Trends Mech. Eng. Select Proc. ICIME 2019, 239 (2020)

Kasman, Ş, Yenier, Z.: Analyzing dissimilar friction stir welding of A5754/AA7075. Int. J. Adv. Manuf. Technol. 70, 145–156 (2014). https://doi.org/10.1007/s00170-013-5256-7

Khodabakhshi, F., Simchi, A., Kokabi, A.H., Gerlich, A.P., Nosko, M.: Effects of post-annealing on the microstructure and mechanical properties of friction stir processed Al–Mg–TiO2 nanocomposites. Mater. Des. 63, 30–41 (2014)

Naik, L.S., Hadya, B., Murahari, K.: Experimental study on AA7075 its effect of rotational speed and tool pin profile on friction stir welding process. Int. J. Inf. Educ. Technol. 9, 3 (2018)

Naik, L.S., Hadya, B., Prasad, T., Sreenivas Rao, P.C.: Friction stir welding tool pin shape effects on mechanical properties and microstructure on AZ91 under water conditions (2022)

Asadi, P., Givi, M.K.B., Parvin, N.: on the role of cooling and tool rotational direction on microstructure and mechanical properties of friction stir processed AZ91. Int. J. Adv. Manuf. Technol. 63, 987–997 (2012). https://doi.org/10.1007/s00170-012-3971-0

Siddani, J.K., Srinivas, C., Reddy, N.M.M., Naik, L.S.: Investigation of process parameters of ultrasonic welding of copper using Taguchi and grey relational analysis. Mater. Today: Proc. 44, 827–831 (2021)

Shankar, S., Mehta, K.P., Chattopadhyaya, S., Vilaça, P.: Dissimilar friction stir welding of Al to non-Al metallic materials: an overview. Mater. Chem. Phys. 9, 126371 (2022)

Ahmadifard, S., Heidarpour, A., Kazemi, S.: The effects of pass number and nano-size ZrO2 powder on the mechanical, microstructure and wear behavior in friction stir welding of the Al-5083. Modares Mech. Eng. 18(3), 219–27 (2018)

Bahrami, M., Farahmand Nikoo, M., Besharati Givi, M.K.: Microstructural and mechanical behaviors of nano-SiC-reinforced AA7075-O FSW joints prepared through two passes. Mater. Sci. Eng. A 626, 220–228 (2015). https://doi.org/10.1016/j.msea.2014.12.009

Singh, T., Tiwari, S.K., Shukla, D.K.: Friction-stir welding of AA6061-T6: the effects of Al2O3 nano-particles addition. Results Mater. 1, 100005 (2019)

Heidarpour, A., Ahmadifard, S., Kazemi, S.: Fabrication and characterization of Al5083/Al2O3 surface nanocomposite via friction stir processing. J. Adv. Mater. Process. 5, 11–24 (2017)

Mirjavadi, S.S., Alipour, M., Soheil Emamian, S., Kord, A.M.S.H., Koppad, P.G., Keshavamurthy, R.: Influence of TiO2 nanoparticles incorporation to friction stir welded 5083 aluminum alloy on the microstructure, mechanical properties and wear resistance. J. Alloy. Compd. 712, 795–803 (2017)

Sahlot, P., Kaushal Jha, G.K., Dey, A.A.: Quantitative wear analysis of H13 steel tool during friction stir welding of Cu-0.8%Cr-0.1%Zr alloy. Wear 378–379, 82–89 (2017). https://doi.org/10.1016/j.wear.2017.02.009

Khanna, N., Sharma, P., Bharati, M., Badheka, V.J.: Friction stir welding of dissimilar aluminium alloys AA 6061–T6 and AA 8011–h14: a novel study. J Brazil Soc Mech Sci Eng 42(1), 7 (2020). https://doi.org/10.1007/s40430-019-2090-3

Shankar, S., Vilaça, P., Dash, P., Chattopadhyaya, S., Hloch, S.: Joint strength evaluation of friction stir welded Al-Cu dissimilar alloys. Measurement (2019). https://doi.org/10.1016/j.measurement.2019.07.019

Arun Kumar, R., Vaira Vignesh, R., Srirangarajalu, N., Padmanaban, R.: Examination of the mechanical, corrosion, and tribological behavior of friction stir welded aluminum alloy AA8011. Trans. Marit. Sci. 10, 20–41 (2021). https://doi.org/10.7225/toms.v10.n01.002

Mao, W.-W., Ning, A.-G., Guo, H.-J.: Nanoscale precipitates and comprehensive strengthening mechanism in AISI H13 steel. Int. J. Miner. Metall. Mater. 23(9), 1056–1064 (2016). https://doi.org/10.1007/s12613-016-1323-z

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lonavath, S.N., Boda, H. Consequences of the rotational speed and profile of tool pin in microstructure and mechanical properties of AA8011/ZrO2 composite produced by FSW. Int J Interact Des Manuf (2023). https://doi.org/10.1007/s12008-023-01295-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-023-01295-8