Abstract

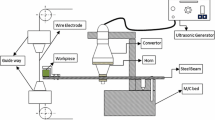

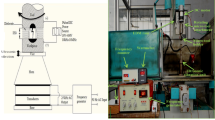

With the continuous improvement in manufacturing processes there is an amalgamation of digital technology with traditional concepts. Electric discharge machining is one such example of it. The more industries digitalize it the more is the degree of automation. In present experimental work ZNC Electrical Discharge Machine has been used to perform the experiments. Total 18 experiments have been performed on Inconel 625 alloy as per the orthogonal array prepared by Minitab software. Tool electrode, peak current, pulse on time (Ton) and pulse of time (Toff) are considered as input parameters. There were two levels of tool and rest were assigned three levels. 9 experiments were conducted via copper tool without vibration and in remaining 9 experiments vibration assisted copper tool was used. Vibration was given to tool with coin vibration motor which was powered by battery. It was observed that when Toff was increased from 25 to 35 µs the surface roughness enhances by 23.23%. Also, it was found that circularity improves by 25.85% when Ton is raised from 140 to 160 µs. Surface roughness of each drilled hole was measured using surface roughness tester and circularity was measured using Quick Image. The FESEM and EDS has performed on the machined specimen to analyze the microstructure and chemical composition.

Similar content being viewed by others

References

Talla, G., Gangopadhyay, S., Biswas, C.K.: Effect of powder-suspended dielectric on the EDM characteristics of Inconel 625. J. Mater. Eng. Perform. 25(2), 704–717 (2015). https://doi.org/10.1007/S11665-015-1835-0

Subrahmanyam, M., Nancharaiah, T.: Optimization of process parameters in wire-cut EDM of Inconel 625 using Taguchi’s approach. Mater. Today: Proc. 23, 642–646 (2020). https://doi.org/10.1016/j.matpr.2019.05.449

Mausam, K., Kumar Singh, P., Sharma, K., Gupta, R.C.: Investigation of process parameter of EDM using genetic algorithm (GA) approach for carbon fiber based two phase epoxy composites. Mater. Today: Proc. 3(10), 4102–4108 (2016). https://doi.org/10.1016/j.matpr.2016.11.081

Mertiya, A.S., et al.: Development and investigation of an inexpensive low frequency vibration platform for enhancing the performance of electrical discharge machining process. Materials 14(20), 6192 (2021). https://doi.org/10.3390/ma14206192

Teimouri, R., Baseri, H.: Improvement of dry EDM process characteristics using artificial soft computing methodologies. Prod. Eng. Res. Dev. 6(4–5), 493–504 (2012). https://doi.org/10.1007/s11740-012-0398-2

Goyal, A., Pandey, A., Sharma, P.: Machinability of Inconel 625 aerospace material using cryogenically treated WEDM. Solid State Phenom. 266, 38–42 (2017). https://doi.org/10.4028/WWW.SCIENTIFIC.NET/SSP.266.38

Goyal, A., Pandey, A., Sharma, P.: Investigation of surface roughness for Inconel 625 using wire electric discharge machining. IOP Conf. Ser. Mater. Sci. Eng. 377(1), 012109 (2018). https://doi.org/10.1088/1757-899X/377/1/012109

Unune, D.R., Nirala, C.K., Mali, H.S.: Accuracy and quality of micro-holes in vibration assisted micro-electro-discharge drilling of Inconel 718. Measurement 135, 424–437 (2019). https://doi.org/10.1016/J.MEASUREMENT.2018.11.067

Teimouri, R., Baseri, H.: Experimental study of rotary magnetic field-assisted dry EDM with ultrasonic vibration of workpiece. Int. J. Adv. Manuf. Technol. 67(5), 1371–1384 (2012). https://doi.org/10.1007/S00170-012-4573-6

Somashekhar, K.P., Ramachandran, N., Mathew, J.: Optimization of material removal rate in micro-EDM using artificial neural network and genetic algorithms. Mater. Manuf. Process. 25(6), 467–475 (2010). https://doi.org/10.1080/10426910903365760

Srivastava, V., Pandey, P.M.: Effect of process parameters on the performance of EDM process with ultrasonic assisted cryogenically cooled electrode. J. Manuf. Process. 14(3), 393–402 (2012). https://doi.org/10.1016/J.JMAPRO.2012.05.001

Zhang, L., Jia, Z., Wang, F., Liu, W.: A hybrid model using supporting vector machine and multi-objective genetic algorithm for processing parameters optimization in micro-EDM. Int. J. Adv. Manuf. Technol. 51(5–8), 575–586 (2010). https://doi.org/10.1007/s00170-010-2623-5

Unune, D.R., Mali, H.S.: Experimental investigation on low-frequency vibration-assisted µ-ED milling of Inconel 718. Eng. Sci. Technol. Int. J. 20(1), 222–231 (2017). https://doi.org/10.1016/j.jestch.2016.06.010

Kumar, A., Kumar, V., Kumar, J.: Surface crack density and recast layer thickness analysis in WEDM process through response surface methodology. Mach. Sci. Technol. 20(2), 201–230 (2016). https://doi.org/10.1080/10910344.2016.1165835

Huu, P.N., et al.: Multi-objective optimization of process parameter in EDM using low-frequency vibration of workpiece assigned for SKD61. Sadhana Acad. Proc. Eng. Sci. (2019). https://doi.org/10.1007/S12046-019-1185-Y

Mohanty, C.P., Mahapatra, S.S., Singh, M.R.: An intelligent approach to optimize the EDM process parameters using utility concept and QPSO algorithm. Eng. Sci. Technol. Int. J. 20(2), 552–562 (2017). https://doi.org/10.1016/j.jestch.2016.07.003

Endo, T., Tsujimoto, T., Mitsui, K.: Study of vibration-assisted micro-EDM—the effect of vibration on machining time and stability of discharge. Precis. Eng. 32(4), 269–277 (2008). https://doi.org/10.1016/J.PRECISIONENG.2007.09.003

Rahul, S., Datta, B., Biswal, B., Mahapatra, S.S.: A novel satisfaction function and distance-based approach for machining performance optimization during electro-discharge machining on super alloy inconel 718. Arab. J. Sci. Eng. 42(5), 1999–2020 (2017). https://doi.org/10.1007/s13369-017-2422-5

Lee, P.A., Kim, Y., Kim, B.H.: Effect of low frequency vibration on micro EDM drilling. Int. J. Precis. Eng. Manuf. 16(13), 2617–2622 (2015). https://doi.org/10.1007/S12541-015-0335-3

Kumar, S., Gupta, A.K., Chandna, P., Bhushan, G., Kumar, A.: A novel approach of GEF and GA for the optimization of multi-objective wire EDM process during the machining of DC53 super alloy. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 235(4), 1119–1131 (2021). https://doi.org/10.1177/0954408921992918

Le, Q.D., Nguyen, H.P., Banh, T.L., Nguyen, D.T.: Comparative study of low-frequency vibrations assigned to a workpiece in EDM and PMEDM. Int. J. Mod. Phys. B (2020). https://doi.org/10.1142/S0217979220401451

Kumaran, S.T., Ko, T.J., Kurniawan, R.: Grey fuzzy optimization of ultrasonic-assisted EDM process parameters for deburring CFRP composites. Meas. J. Int. Meas. Confed. 123, 203–212 (2018). https://doi.org/10.1016/j.measurement.2018.03.076

Nguyen, H.P., Ngo, N.V., Nguyen, Q.T.: Optimizing process parameters in edm using low frequency vibration for material removal rate and surface roughness. J. King Saud Univ. Eng. Sci, 33(4), 284–291 (2021). https://doi.org/10.1016/j.jksues.2020.05.002

Pandey, A., Goyal, A., Meghvanshi, R.: Experimental Investigation and optimization of machining parameters of aerospace material using taguchi’s DOE approach. Mater. Today Proc. 4(8), 7246–7251 (2017). https://doi.org/10.1016/J.MATPR.2017.07.053

Prihandana, G.S., Mahardika, M., Hamdi, M., Mitsui, K.: Effect of low-frequency vibration on workpiece in EDM processes. J. Mech. Sci. Technol. 25(5), 1231–1234 (2011). https://doi.org/10.1007/S12206-011-0307-1

Goyal, A.: Investigation of material removal rate and surface roughness during wire electrical discharge machining (WEDM) of Inconel 625 super alloy by cryogenic treated tool electrode. J. King Saud Univ. Sci. 29(4), 528–535 (2017). https://doi.org/10.1016/J.JKSUS.2017.06.005

Tsai, M.Y., Fang, C.S., Yen, M.H.: Vibration-assisted electrical discharge machining of grooves in a titanium alloy (Ti-6A-4V). Int, J. Adv. Manuf. Technol. 97(1), 297–304 (2018). https://doi.org/10.1007/S00170-018-1904-2

Bhatt, D., Goyal, A.: Multi-objective optimization of machining parameters in wire EDM for AISI-304. Mater. Today Proc. 18, 4227–4242 (2019). https://doi.org/10.1016/J.MATPR.2019.07.381

Shitara, T., Fujita, K., Yan, J.: Direct observation of discharging phenomena in vibration-assisted micro-electrical discharge machining. Int. J. Adv. Manuf. Technol. 108(4), 1125–1138 (2020). https://doi.org/10.1007/S00170-019-04877-7

Kumawat, A., Goyal, A., Dadhich, M., Gupta, R.: Development and optimization of triangular profile by using wire EDM machining process. Mater. Today Proc. 28, 2369–2374 (2020). https://doi.org/10.1016/J.MATPR.2020.04.645

Muthu, P.: Multi objective optimization of wear behaviour of aluminum MMCs using Grey-Taguchi method. Manuf. Rev. (2020). https://doi.org/10.1051/mfreview/2020013

Jung, J.H., Kwon, W.T.: Optimization of EDM process for multiple performance characteristics using Taguchi method and Grey relational analysis. J. Mech. Sci. Technol. 24,1083–1090 (2010). https://doi.org/10.1007/s12206-010-0305-8

Singh, O., Kumar, G., Electronica, M.K.A, et al.: Role of taguchi and grey relational method in optimization of machining parameters of different materials: a review. Acta. Electron. Malays. 3(1), 19–22 (2019). https://doi.org/10.26480/aem.01.2019.19.22

Lin, Y.C., Lee, H.S.: Optimization of machining parameters using magnetic-force-assisted EDM based on gray relational analysis. Int. J. Adv. Manuf. Technol. 42(11–12), 1052–1064 (2009). https://doi.org/10.1007/S00170-008-1662-7

Palanisamy, D., Manikandan, N., Ramesh, R., Kathirvelan, M., Arulkirubakaran, D.: Machinability analysis and optimization of wire-EDM textured conventional tungsten carbide inserts in machining of 17–4 PH stainless steel. Mater. Today Proc. 1(39), 359–367 (2021)

Manikandan, N., Arulkirubakaran, D., Palanisamy, D., Raju, R.: Influence of wire-EDM textured conventional tungsten carbide inserts in machining of aerospace materials (Ti–6Al–4V alloy). Mater. Manuf. Process. 34(1), 103–111 (2019)

Arunbharathi, R., Varthanan, P.A., Akilesh, M., Raju, R.A., Kumar, G.A.: Experimental investigation and optimization of process parameters in WEDM on machining of H13 steel using response surface methodology. Indian J. Eng. Sci. Technol. 11(1), 39 (2017)

Kale, B.S., Bhole, K.S., Dhongadi, H., Oak, S., Deshmukh, P., Oza, A., Ramesh, R.: Effect of polygonal surfaces on development of viscous fingering in lifting plate Hele-Shaw cell. Int. J. Interact. Des. Manuf. IJIDeM (2022). https://doi.org/10.1007/s12008-022-01030-9

Shinde, S.M., Lekurwale, R.R., Bhole, K.S., Oza, A.D., Patil, A.S., Ramesh, R.: 5-axis virtual machine tool centre building in PLM environment. Int. J. Interact. Des. Manuf. IJIDeM (2022). https://doi.org/10.1007/s12008-022-00974-2

Gautam, N., Goyal, A., Sharma, S.S., Oza, A.D., Kumar, R.: Study of various optimization techniques for electric discharge machining and electrochemical machining processes. Mater. Today: Proc. 57, 615–621 (2022)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sharma, A.K., Singh, V., Goyal, A. et al. Experimental analysis of Inconel 625 alloy to enhance the dimensional accuracy with vibration assisted micro-EDM. Int J Interact Des Manuf (2023). https://doi.org/10.1007/s12008-023-01228-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-023-01228-5