Abstract

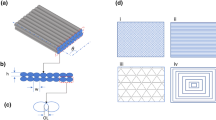

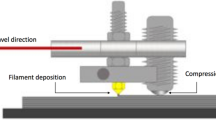

Additive manufacturing techniques are widely used in the present manufacturing era because of their ability to manufacture intricate products. Fused filament fabrication (FFF) is one of the most commonly adopted additive manufacturing technology, which involves the extrusion of the semi-solid polymer through the nozzle to be deposited in layers to form the part. In FFF, the polymer melt being deposited, forms the bonds with the neighboring pre-deposited melt during the part fabrication. The pre-deposited melt is at the low temperature compared to the polymer melt extruding out of the nozzle; hence the heat transfer occurs due to temperature gradient by the mode of conduction and convection. The commercialization of the FFF technology in a wide range of industrial applications still seems to be constrained due to several drawbacks such as insufficient mechanical properties, poor surface quality, and low dimensional accuracy. The grade of FFF-produced products is affected by various process parameters, for example, layer thickness, build orientation, raster width, or print speed. In FFF, process parameters are optimized to improve the quality of the final printed part. The cost of post-processing is also reduced as a result of parameter optimization. In this study, the influence of the convection coefficient on bond formation was investigated, and a model for predicting bond size in terms of convection coefficient is discussed for a given set of parameters. This work also aims to study the effects of thermal properties on neck formation and the effects of neck formation on strength, surface finish, and dimensional accuracy of the printed parts. In addition, this study reveals the problems and difficulties found in previous works, potential future scope in this area has been analyzed, and new research approaches are suggested.

Similar content being viewed by others

References

Bellehumeur, C., Li, L., Sun, Q., Gu, P.: Modeling of bond formation between polymer filaments in the fused deposition modeling process. J. Manuf. Process. 6, 170–178 (2004). https://doi.org/10.1016/S1526-6125(04)70071-7

Ravi, A.K., Deshpande, A., Hsu, K.H.: An in-process laser localized pre-deposition heating approach to inter-layer bond strengthening in extrusion based polymer additive manufacturing. J. Manuf. Process. 24, 179–185 (2016). https://doi.org/10.1016/j.jmapro.2016.08.007

Gurrala, P.K., Regalla, S.P.: Part strength evolution with bonding between filaments in fused deposition modelling: this paper studies how coalescence of filaments contributes to the strength of final FDM part. Virtual Phys. Prototyp. 9, 141–149 (2014). https://doi.org/10.1080/17452759.2014.913400

Chacón, J.M., Caminero, M.A., García-Plaza, E., Núñez, P.J.: Additive manufacturing of PLA structures using fused deposition modelling: effect of process parameters on mechanical properties and their optimal selection. Mater. Des. 124, 143–157 (2017). https://doi.org/10.1016/j.matdes.2017.03.065

Turner, B.N., Strong, R., Gold, S.A.: A review of melt extrusion additive manufacturing processes: I. Process design and modeling. Rapid Prototyp. J. 20, 192–204 (2014). https://doi.org/10.1108/RPJ-01-2013-0012

Rao, Y., Wei, N., Yao, S., Wang, K., Peng, Y.: A process-structure-performance modeling for thermoplastic polymers via material extrusion additive manufacturing. Addit. Manuf. 39, 101857 (2021). https://doi.org/10.1016/j.addma.2021.101857

Krishnanand, S., Soni, S., Nayak, A., Taufik, M.: Generation of tool path in fused filament fabrication. In: Lect. Notes Mech. Eng., Springer Science and Business Media Deutschland GmbH, 2021: pp. 153–161. https://doi.org/10.1007/978-981-16-3033-0_14

Kishore, V., A**jeru, C., Nycz, A., Post, B., Lindahl, J., Kunc, V., Duty, C.: Infrared preheating to improve interlayer strength of big area additive manufacturing (BAAM) components. Addit. Manuf. 14, 7–12 (2017). https://doi.org/10.1016/j.addma.2016.11.008

Tamburrino, F., Barone, S., Paoli, A., Razionale, A.V.: Post-processing treatments to enhance additively manufactured polymeric parts: a review. Virtual Phys. Prototyp. 16, 218–251 (2021). https://doi.org/10.1080/17452759.2021.1917039

Lavecchia, F., Guerra, M.G., Galantucci, L.M.: Chemical vapor treatment to improve surface finish of 3D printed polylactic acid (PLA) parts realized by fused filament fabrication. Prog. Addit. Manuf. 7, 65–75 (2022). https://doi.org/10.1007/s40964-021-00213-2

Vaezi, M., Yang, S.: Extrusion-based additive manufacturing of PEEK for biomedical applications. Virtual Phys. Prototyp. 10, 123–135 (2015). https://doi.org/10.1080/17452759.2015.1097053

Ngo, T.D., Kashani, A., Imbalzano, G., Nguyen, K.T.Q., Hui, D.: Additive manufacturing (3D printing): a review of materials, methods, applications and challenges. Compos. Part B Eng. 143, 172–196 (2018). https://doi.org/10.1016/j.compositesb.2018.02.012

Podroužek, J., Marcon, M., Ninčević, K., Wan-Wendner, R.: Bio-inspired 3D infill patterns for additive manufacturing and structural applications. Materials (Basel). 12, 499 (2019). https://doi.org/10.3390/ma12030499

Cholleti, E.R., Gibson, I.: ABS nano composite materials in additive manufacturing. IOP Conf. Ser. Mater. Sci. Eng. (2018). https://doi.org/10.1088/1757-899X/455/1/012038

Serdeczny, M.P., Comminal, R., Pedersen, D.B., Spangenberg, J.: Numerical simulations of the mesostructure formation in material extrusion additive manufacturing. Addit. Manuf. 28, 419–429 (2019). https://doi.org/10.1016/j.addma.2019.05.024

Kim, M.K., Lee, I.H., Kim, H.C.: Effect of fabrication parameters on surface roughness of FDM parts. Int. J. Precis. Eng. Manuf. 19, 137–142 (2018). https://doi.org/10.1007/s12541-018-0016-0

Sun, Q., Rizvi, G.M., Bellehumeur, C.T., Gu, P.: Effect of processing conditions on the bonding quality of FDM polymer filaments. Rapid Prototyp. J. 14, 72–80 (2008). https://doi.org/10.1108/13552540810862028

Li, L., Sun, Q., Bellehumeur, C., Gu, P.: Investigation of bond formation in FDM process investigation of bond formation in FDM process. Trans. North Am. Manuf. Res. Inst. SME. 31, 400–407 (2019)

Bhalodi, D.V., Zalavadiya, K.S., Gurrala, P.K.: Parametric study to predict the bond formation in FDM process. Int. J. Mater. Mech. Manuf. 6, 313–316 (2018)

Syrlybayev, D., Zharylkassyn, B., Seisekulova, A., Akhmetov, M., Perveen, A., Talamona, D.: Optimisation of strength properties of FDM printed parts—a critical review. Polymers (Basel). 13, 1587 (2021). https://doi.org/10.3390/polym13101587

Dey, A., Yodo, N.: A systematic survey of FDM process parameter optimization and their influence on part characteristics. J. Manuf. Mater. Process. 3, 64 (2019). https://doi.org/10.3390/jmmp3030064

Garzon-Hernandez, S., Garcia-Gonzalez, D., Jérusalem, A., Arias, A.: Design of FDM 3D printed polymers: an experimental-modelling methodology for the prediction of mechanical properties. Mater. Des. 188, 108414 (2020). https://doi.org/10.1016/j.matdes.2019.108414

Conley, W.H., Deferrari, R.J.: Principles and applications. J. Higher Educ. 23, 225 (1952). https://doi.org/10.2307/1976787

Rodríguez, J.F., Thomas, J.P., Renaud, J.E.: Mechanical behavior of acrylonitrile butadiene styrene (ABS) fused deposition materials. Experimental investigation. Rapid Prototyp. J. 7, 148–158 (2001). https://doi.org/10.1108/13552540110395547

Dhinesh, S.K., Arun Prakash, S., Senthil Kumar, K.L., Megalingam, A.: Study on flexural and tensile behavior of PLA, ABS and PLA-ABS materials. Mater. Today Proc. (2021). https://doi.org/10.1016/j.matpr.2020.03.546

Wang, P., Zou, B., Ding, S.: Modeling of surface roughness based on heat transfer considering diffusion among deposition filaments for FDM 3D printing heat-resistant resin. Appl. Therm. Eng. 161, 114064 (2019). https://doi.org/10.1016/j.applthermaleng.2019.114064

Raju, T.N., Ramach, V., Raju, R.: An experimental investigation on surface quality and dimensional accuracy of FDM components, (n.d.). http://citeseerx.ist.psu.edu/viewdoc/summary?doi=10.1.1.670.108 (accessed May 26, 2022).

Popescu, D., Zapciu, A., Amza, C., Baciu, F., Marinescu, R.: FDM process parameters influence over the mechanical properties of polymer specimens: a review. Polym. Test. 69, 157–166 (2018). https://doi.org/10.1016/j.polymertesting.2018.05.020

Yin, J., Lu, C., Fu, J., Huang, Y., Zheng, Y.: Interfacial bonding during multi-material fused deposition modeling (FDM) process due to inter-molecular diffusion. Mater. Des. 150, 104–112 (2018). https://doi.org/10.1016/j.matdes.2018.04.029

Ouballouch, A., Lasri, L., Ouahmane, I., El Alaiji, R., Sallaou, M., Ettaqi, S.: Optimization of PLA parts manufactured by the Fused Deposition Modeling Technology. In: 2018 IEEE Int. Conf. Technol. Manag. Oper. Decis. ICTMOD 2018, Institute of Electrical and Electronics Engineers Inc., 2018;288–292. https://doi.org/10.1109/ITMC.2018.8691133

Jain, P.K., Pandey, P.M., Rao, P.V.M.: Experimental investigations for improving part strength in selective laser sintering. Virtual Phys. Prototyp. 3, 177–188 (2008). https://doi.org/10.1080/17452750802065893

Tao, Y., Wang, H., Li, Z., Li, P., Shi, S.Q.: Development and application ofwood flour-filled polylactic acid composite filament for 3d printing. Materials (Basel) (2017). https://doi.org/10.3390/ma10040339

Vanaei, H., Shirinbayan, M., Deligant, M., Raissi, K., Fitoussi, J., Khelladi, S., Tcharkhtchi, A.: Influence of process parameters on thermal and mechanical properties of <scp>polylactic acid</scp> fabricated by fused filament fabrication. Polym. Eng. Sci. 60, 1822–1831 (2020). https://doi.org/10.1002/pen.25419

Kuznetsov, V., Solonin, A., Urzhumtsev, O., Schilling, R., Tavitov, A.: Strength of PLA components fabricated with fused deposition technology using a desktop 3D printer as a function of geometrical parameters of the process. Polymers (Basel). 10, 313 (2018). https://doi.org/10.3390/polym10030313

Rodríguez-Panes, A., Claver, J., Camacho, A.: The influence of manufacturing parameters on the mechanical behaviour of PLA and ABS pieces manufactured by FDM: a comparative analysis. Materials (Basel). 11, 1333 (2018). https://doi.org/10.3390/ma11081333

Aloyaydi, B., Sivasankaran, S., Mustafa, A.: Investigation of infill-patterns on mechanical response of 3D printed poly-lactic-acid. Polym. Test. 87, 106557 (2020). https://doi.org/10.1016/j.polymertesting.2020.106557

Polylactic Acid: PLA Biopolymer Technology and Applications | Request PDF, (n.d.). https://www.researchgate.net/publication/286177523_Polylactic_Acid_PLA_Biopolymer_Technology_and_Applications (accessed May 20, 2022)

Yan, Y., Zhang, R., Hong, G., Yuan, X.: Research on the bonding of material paths in melted extrusion modeling. Mater. Des. 21, 93–99 (2000). https://doi.org/10.1016/s0261-3069(99)00058-8

Triyono, J., Sukanto, H., Saputra, R.M., Smaradhana, D.F.: The effect of nozzle hole diameter of 3D printing on porosity and tensile strength parts using polylactic acid material. Open Eng. 10, 762–768 (2020). https://doi.org/10.1515/eng-2020-0083

Chua, B.-L., Baek, S.-H., Park, K., Ahn, D.-G.: Numerical investigation of deposition characteristics of PLA on an ABS plate using a material extrusion process. Materials (Basel). 14, 3404 (2021). https://doi.org/10.3390/ma14123404

Abeykoon, C., Sri-Amphorn, P., Fernando, A.: Optimization of fused deposition modeling parameters for improved PLA and ABS 3D printed structures. Int. J. Light. Mater. Manuf. 3, 284–297 (2020). https://doi.org/10.1016/j.ijlmm.2020.03.003

Partain, S.C.: Fused deposition modeling with localized pre-deposition heating using forced air, Montana State University - Bozeman, College of Engineering, 2007. https://scholarworks.montana.edu/xmlui/bitstream/1/2016/1/PartainS0507.pdf (accessed May 26, 2022)

Bellini, A., Güçeri, S.: Mechanical characterization of parts fabricated using fused deposition modeling. Rapid Prototyp. J. 9, 252–264 (2003). https://doi.org/10.1108/13552540310489631

Yardimci, M.A., Güçeri, S.: Conceptual framework for the thermal process modelling of fused deposition. Rapid Prototyp. J. 2, 26–31 (1996). https://doi.org/10.1108/13552549610128206

Zmeskal, O., Marackova, L., Lapcikova, T., Mencik, P., Prikryl, R.: Thermal properties of samples prepared from polylactic acid by 3D printing, in: AIP Conf. Proc., American Institute of Physics Inc., 2020;020022. https://doi.org/10.1063/5.0033857

Jiang, K.Y., Gu, Y.H.: Controlling parameters for polymer melting and extrusion in FDM. Key Eng. Mater. (2004). https://doi.org/10.4028/www.scientific.net/kem.259-260.667

Vollmer, M., Möllmann, K.-P.: Some basic concepts of heat transfer. 2010. https://doi.org/10.1002/9783527630868.ch4

Pokluda, O., Bellehumeur, C.T., Vlachopoulos, J.: Modification of Frenkel’s model for sintering. AIChE J. 43, 3253–3256 (1997). https://doi.org/10.1002/aic.690431213

Sood, A.K., Ohdar, R.K., Mahapatra, S.S.: Parametric appraisal of mechanical property of fused deposition modelling processed parts. Mater. Des. 31, 287–295 (2010). https://doi.org/10.1016/j.matdes.2009.06.016

Nickel, A.H., Barnett, D.M., Prinz, F.B.: Thermal stresses and deposition patterns in layered manufacturing. Mater. Sci. Eng. A. 317, 59–64 (2001). https://doi.org/10.1016/S0921-5093(01)01179-0

Anitha, R., Arunachalam, S., Radhakrishnan, P.: Critical parameters influencing the quality of prototypes in fused deposition modelling. J. Mater. Process. Technol. (2001). https://doi.org/10.1016/S0924-0136(01)00980-3

Coogan, T.J., Kazmer, D.O.: Bond and part strength in fused deposition modeling. Rapid Prototyp. J. 23, 414–422 (2017). https://doi.org/10.1108/RPJ-03-2016-0050

Shofner, M.L., Lozano, K., Rodríguez-Macías, F.J., Barrera, E.V.: Nanofiber-reinforced polymers prepared by fused deposition modeling. J. Appl. Polym. Sci. 89, 3081–3090 (2003). https://doi.org/10.1002/app.12496

Sezer, H.K., Eren, O.: FDM 3D printing of MWCNT re-inforced ABS nano-composite parts with enhanced mechanical and electrical properties. J. Manuf. Process. 37, 339–347 (2019). https://doi.org/10.1016/j.jmapro.2018.12.004

Dul, S., Fambri, L., Pegoretti, A.: Filaments production and fused deposition modelling of ABS/carbon nanotubes composites. Nanomaterials (2018). https://doi.org/10.3390/nano8010049

Bardot, M., Schulz, M.D.: Biodegradable Poly(Lactic Acid) nanocomposites for fused deposition modeling 3D printing. Nanomaterials 10, 2567 (2020). https://doi.org/10.3390/nano10122567

Coppola, B., Cappetti, N., Di Maio, L., Scarfato, P., Incarnato, L.: 3D printing of PLA/clay nanocomposites: influence of printing temperature on printed samples properties. Materials (Basel). 11, 1947 (2018). https://doi.org/10.3390/ma11101947

Qiu, D., Langrana, N.A.: Void eliminating toolpath for extrusion-based multi-material layered manufacturing. Rapid Prototyp. J. 8, 38–45 (2002). https://doi.org/10.1108/13552540210413293

Mamaghani Shishavan, S., Azdast, T., Rash Ahmadi, S.: Investigation of the effect of nanoclay and processing parameters on the tensile strength and hardness of injection molded Acrylonitrile Butadiene Styrene-organoclay nanocomposites. Mater. Des. 58, 527–534 (2014). https://doi.org/10.1016/j.matdes.2014.02.014

Pavlidou, S., Papaspyrides, C.D.: A review on polymer-layered silicate nanocomposites. Prog. Polym. Sci. 33, 1119–1198 (2008). https://doi.org/10.1016/j.progpolymsci.2008.07.008

Francis, V., Jain, P.K.: Experimental investigations on fused deposition modelling of polymer-layered silicate nanocomposite. Virtual Phys. Prototyp. 11, 109–121 (2016). https://doi.org/10.1080/17452759.2016.1172431

Rajpurohit, S.R., Dave, H.K.: Effect of process parameters on tensile strength of FDM printed PLA part. Rapid Prototyp. J. 24, 1317–1324 (2018). https://doi.org/10.1108/RPJ-06-2017-0134

Hernandez, R., Slaughter, D., Whaley, D., Tate, J., Asiabanpour, B., Analyzing the tensile, compressive, and flexural properties of 3D printed ABS P430 plastic based on printing orientation using fused deposition modeling, Solid Free. Fabr. 2016 Proc. 27th Annu. Int. Solid Free. Fabr. Symp. - An Addit. Manuf. Conf. SFF 2016. 2016;939–950

Ziemian, S., Okwara, M., Ziemian, C.W.: Tensile and fatigue behavior of layered acrylonitrile butadiene styrene. Rapid Prototyp. J. 21, 270–278 (2015). https://doi.org/10.1108/RPJ-09-2013-0086

Jain, P.K., Pandey, P.M., Rao, P.V.M.: Effect of delay time on part strength in selective laser sintering. Int. J. Adv. Manuf. Technol. 43, 117–126 (2009). https://doi.org/10.1007/S00170-008-1682-3

Garg, A., Bhattacharya, A.: An insight to the failure of FDM parts under tensile loading: finite element analysis and experimental study. Int. J. Mech. Sci. 120, 225–236 (2017). https://doi.org/10.1016/j.ijmecsci.2016.11.032

Aliheidari, N., Tripuraneni, R., Ameli, A., Nadimpalli, S.: Fracture resistance measurement of fused deposition modeling 3D printed polymers. Polym. Test. 60, 94–101 (2017). https://doi.org/10.1016/j.polymertesting.2017.03.016

(PDF) Prediction of neck growth due to inter and intra-layer bonding for high strength parts in additive manufacturing, (n.d.). https://www.researchgate.net/publication/264545454_Prediction_of_Neck_Growth_due_to_Inter_and_Intra-Layer_Bonding_for_High_Strength_Parts_in_Additive_Manufacturing (accessed May 20, 2022)

Chadha, A., Ul Haq, M.I., Raina, A., Singh, R.R., Penumarti, N.B., Bishnoi, M.S.: Effect of fused deposition modelling process parameters on mechanical properties of 3D printed parts. World J. Eng. 16, 550–559 (2019). https://doi.org/10.1108/WJE-09-2018-0329

Ćwikła, G., Grabowik, C., Kalinowski, K., Paprocka, I., Ociepka, P.: The influence of printing parameters on selected mechanical properties of FDM/FFF 3D-printed parts. In: IOP Conf. Ser. Mater. Sci. Eng., Institute of Physics Publishing, 2017;012033. https://doi.org/10.1088/1757-899X/227/1/012033

Kulkarni, P., Dutta, D.: Deposition strategies and resulting part stiffnesses in fused deposition modeling. J. Manuf. Sci. Eng. Trans. ASME. 121, 93–103 (1999). https://doi.org/10.1115/1.2830582

Ang, K.C., Leong, K.F., Chua, C.K., Chandrasekaran, M.: Investigation of the mechanical properties and porosity relationships in fused deposition modelling-fabricated porous structures. Rapid Prototyp. J. 12, 100–105 (2006). https://doi.org/10.1108/13552540610652447

Zhang, Y., Chou, K.: A parametric study of part distortions in fused deposition modelling using three-dimensional finite element analysis. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 222, 959–968 (2008). https://doi.org/10.1243/09544054JEM990

Radhwan, H., Shayfull, Z., Abdellah, A.E.H., Irfan, A.R., Kamarudin, K.: Optimization parameter effects on the strength of 3D-printing process using Taguchi method. In: AIP Conf. Proc., American Institute of Physics Inc., 2019;020154. https://doi.org/10.1063/1.5118162

Vicente, C.M.S., Martins, T.S., Leite, M., Ribeiro, A., Reis, L.: Influence of fused deposition modeling parameters on the mechanical properties of ABS parts. Polym. Adv. Technol. 31, 501–507 (2020). https://doi.org/10.1002/pat.4787

Croccolo, D., De Agostinis, M., Olmi, G.: Experimental characterization and analytical modelling of the mechanical behaviour of fused deposition processed parts made of ABS-M30. Comput. Mater. Sci. 79, 506–518 (2013). https://doi.org/10.1016/j.commatsci.2013.06.041

Reddy, B.V., Reddy, N.V., Ghosh, A.: Fused deposition modelling using direct extrusion. Virtual Phys. Prototyp. 2, 51–60 (2007). https://doi.org/10.1080/17452750701336486

A Visual Tool to Improve Layered Manufacturing Part Quality, (n.d.). https://repositories.lib.utexas.edu/handle/2152/73466 (accessed May 26, 2022)

Sahu, R.K., Mahapatra, S.S., Sood, A.K.: A study on dimensional accuracy of fused deposition modeling (FDM) processed parts using fuzzy logic. J. Manuf. Sci. Prod. 13, 183–197 (2014). https://doi.org/10.1515/jmsp-2013-0010

Bhalodi, D., Zalavadiya, K., Gurrala, P.K.: Influence of temperature on polymer parts manufactured by fused deposition modeling process. J. Brazilian Soc. Mech. Sci. Eng. 41, 1–11 (2019). https://doi.org/10.1007/s40430-019-1616-z

Akande, S.O.: Dimensional accuracy and surface finish optimization of fused deposition modelling parts using desirability function analysis. Int. J. Eng. Res. (2015). https://doi.org/10.17577/ijertv4is040393

Wang, T.M., **, J.T., **, Y.: A model research for prototype warp deformation in the FDM process. Int. J. Adv. Manuf. Technol. 33, 1087–1096 (2007). https://doi.org/10.1007/s00170-006-0556-9

**aoyong, S., Liangcheng, C., Honglin, M., Peng, G., Zhanwei, B., Cheng, L.: Experimental analysis of high temperature PEEK materials on 3D printing test. In: Proc. - 9th Int. Conf. Meas. Technol. Mechatronics Autom. ICMTMA 2017, Institute of Electrical and Electronics Engineers Inc., 2017; 13–16. https://doi.org/10.1109/ICMTMA.2017.0012

Tardif, X., Pignon, B., Boyard, N., Schmelzer, J.W.P., Sobotka, V., Delaunay, D., Schick, C.: Experimental study of crystallization of PolyEtherEtherKetone (PEEK) over a large temperature range using a nano-calorimeter. Polym. Test. 36, 10–19 (2014). https://doi.org/10.1016/j.polymertesting.2014.03.013

Wu, W.Z., Geng, P., Zhao, J., Zhang, Y., Rosen, D.W., Zhang, H.B.: Manufacture and thermal deformation analysis of semicrystalline polymer polyether ether ketone by 3D printing. Mater. Res. Innov. 18, S5-12-S5-16 (2014). https://doi.org/10.1179/1432891714Z.000000000898

Durgun, I., Ertan, R.: Experimental investigation of FDM process for improvement of mechanical properties and production cost. Rapid Prototyp. J. 20, 228–235 (2014). https://doi.org/10.1108/RPJ-10-2012-0091

Jatti, V.S., Jatti, S.V., Patel, A.P., Jatti, V.S.: A study on effect of fused deposition modeling process parameters on mechanical properties. Int. J. Sci. Technol. Res. 8, 689–693 (2019)

Garg, A., Bhattacharya, A., Batish, A.: Chemical vapor treatment of ABS parts built by FDM: analysis of surface finish and mechanical strength. Int. J. Adv. Manuf. Technol. 89, 2175–2191 (2017). https://doi.org/10.1007/s00170-016-9257-1

Francis, V., Jain, P.K.: Investigation on the effect of surface modification of 3D printed parts by nanoclay and dimethyl ketone, Https://Doi.Org/https://doi.org/10.1080/10426914.2017.1401717. 2017;33:1080–1092. https://doi.org/10.1080/10426914.2017.1401717

Frone, A.N., Batalu, D., Chiulan, I., Oprea, M., Gabor, A.R., Nicolae, C.-A., Raditoiu, V., Trusca, R., Panaitescu, D.M.: Morpho-structural, thermal and mechanical properties of PLA/PHB/cellulose biodegradable nanocomposites obtained by compression molding, extrusion, and 3D printing. Nanomaterials 10, 51 (2019). https://doi.org/10.3390/nano10010051

Suh, C.H., Jung, Y.C., Kim, Y.S.: Effects of thickness and surface roughness on mechanical properties of aluminum sheets. J. Mech. Sci. Technol. 24, 2091–2098 (2010). https://doi.org/10.1007/s12206-010-0707-7

Ahn, D., Kweon, J.H., Kwon, S., Song, J., Lee, S.: Representation of surface roughness in fused deposition modeling. J. Mater. Process. Technol. 209, 5593–5600 (2009). https://doi.org/10.1016/j.jmatprotec.2009.05.016

Vasudevarao, B., Natarajan, D.P., Henderson, M.: Sensitivity of Rp surface finish to process, Solid Free. Fabr. Proc. 2000;251–258. http://prism.asu.edu/publications/papers/paper00_srpsfppv.pdf

Ahn, D., Kim, H., Lee, S.: Surface roughness prediction using measured data and interpolation in layered manufacturing. J. Mater. Process. Technol. 209, 664–671 (2009). https://doi.org/10.1016/j.jmatprotec.2008.02.050

Es-Said, O.S., Foyos, J., Noorani, R., Mendelson, M., Marloth, R., Pregger, B.A.: Effect of layer orientation on mechanical properties of rapid prototyped samples. Mater. Manuf. Process. 15, 107–122 (2000). https://doi.org/10.1080/10426910008912976

Taufik, M., Jain, P.K.: Role of build orientation in layered manufacturing: a review. Int. J. Manuf. Technol. Manag. 27, 47–73 (2013). https://doi.org/10.1504/IJMTM.2013.058637

Chennakesava, P. and Shivraj Narayan, Y.: Fused deposition modeling – insights. Int. Conf. Adv. Des. Manuf. 2014;1345–1350. https://www.researchgate.net/publication/269702639_Fused_Deposition_Modeling_-_Insights (accessed May 26, 2022).

Boschetto, A., Giordano, V., Veniali, F.: 3D roughness profile model in fused deposition modelling. Rapid Prototyp. J. 19, 240–252 (2013). https://doi.org/10.1108/13552541311323254

Ippolito, R., Iuliano, L., Gatto, A.: Benchmarking of rapid prototy** techniques in terms of dimensional accuracy and surface finish. CIRP Ann. - Manuf. Technol. 44, 157–160 (1995). https://doi.org/10.1016/S0007-8506(07)62296-3

Gadelmawla, E.S., Koura, M.M., Maksoud, T.M.A., Elewa, I.M., Soliman, H.H.: Roughness parameters. J. Mater. Process. Technol. 123, 133–145 (2002). https://doi.org/10.1016/S0924-0136(02)00060-2

Galantucci, L.M., Lavecchia, F., Percoco, G.: Experimental study aiming to enhance the surface finish of fused deposition modeled parts. CIRP Ann. - Manuf. Technol. 58, 189–192 (2009). https://doi.org/10.1016/j.cirp.2009.03.071

Huang, B., Singamneni, S.: Raster angle mechanics in fused deposition modelling. J. Compos. Mater. 49, 363–383 (2015). https://doi.org/10.1177/0021998313519153

Górski, F., Kuczko, W., Wichniarek, R.: Influence of process parameters on dimensional accuracy of parts manufactured using fused deposition modelling technology. Adv. Sci. Technol. Res. J. 7, 27–35 (2013). https://doi.org/10.5604/20804075.1062340

Alafaghani, A., Qattawi, A., Alrawi, B., Guzman, A.: Experimental optimization of fused deposition modelling processing parameters: a design-for-manufacturing approach. In: Procedia Manuf., Elsevier B.V., 2017;791–803. https://doi.org/10.1016/j.promfg.2017.07.079

Akhoundi, B., Behravesh, A.H.: Effect of filling pattern on the tensile and flexural mechanical properties of FDM 3D printed products. Exp. Mech. 59, 883–897 (2019). https://doi.org/10.1007/s11340-018-00467-y

Luis Pérez, C.J.: Analysis of the surface roughness and dimensional accuracy capability of fused deposition modelling processes. Int. J. Prod. Res. 40, 2865–2881 (2002). https://doi.org/10.1080/00207540210146099

Hanon, M.M., Zsidai, L., Ma, Q.: Accuracy investigation of 3D printed PLA with various process parameters and different colors. Mater. Today Proc. (2021). https://doi.org/10.1016/j.matpr.2020.12.1246

Beniak, J., Križan, P., Šooš, L., Matuš, M.: Research on shape and dimensional accuracy of FDM produced parts. In: IOP Conf. Ser. Mater. Sci. Eng., Institute of Physics Publishing, 2019; 012030. https://doi.org/10.1088/1757-899X/501/1/012030

Wang, C.C., Lin, T.W., Hu, S.S.: Optimizing the rapid prototy** process by integrating the Taguchi method with the Gray relational analysis. Rapid Prototyp. J. 13, 304–315 (2007). https://doi.org/10.1108/13552540710824814

Nidagundi, V.B., Keshavamurthy, R., Prakash, C.P.S.: Studies on parametric optimization for fused deposition modelling process. Mater. Today Proc. (2015). https://doi.org/10.1016/j.matpr.2015.07.097

Bähr, F., Westkämper, E.: Correlations between influencing parameters and quality properties of components produced by fused deposition modeling. Procedia CIRP (2018). https://doi.org/10.1016/j.procir.2018.03.048

D’Amico, A.A., Debaie, A., Peterson, A.M.: Effect of layer thickness on irreversible thermal expansion and interlayer strength in fused deposition modeling. Rapid Prototyp. J. 23, 943–953 (2017). https://doi.org/10.1108/RPJ-05-2016-0077

Zhou, J.G., Herscovici, D., Chen, C.C.: Parametric process optimization to improve the accuracy of rapid prototyped stereolithography parts. Int. J. Mach. Tools Manuf. 40, 363–379 (2000). https://doi.org/10.1016/S0890-6955(99)00068-1

Raghunath, N., Pandey, P.M.: Improving accuracy through shrinkage modelling by using Taguchi method in selective laser sintering. Int. J. Mach. Tools Manuf. 47, 985–995 (2007). https://doi.org/10.1016/j.ijmachtools.2006.07.001

Acknowledgements

The present work has been funded by the Science and Engineering Research Board- DST under its Start-up Research Grant (SRG) scheme [Grant number: SRG/2019/000943].

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Alam, M.A., Krishnanand, Patel, A. et al. Thermal analysis for improvement of mechanical properties in fused filament fabricated parts. Int J Interact Des Manuf 17, 603–635 (2023). https://doi.org/10.1007/s12008-022-00981-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-022-00981-3