Abstract

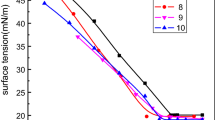

Fluorocarbon surfactants are widely used, especially in the emulsion polymerization of fluoropolymers, due to their high surface activity, excellent stability, and excellent compatibility. However, the long-term environmental pollution of perfluoroalkyl and polyfluoroalkyl groups in fluorocarbon surfactants has made them banned. Here, we designed and prepared an environmentally friendly zwitterionic fluorocarbon surfactant (PFSC) through shortening fluorocarbon chains and covalent bonding them with the zwitterionic groups, and further demonstrated the effect on the emulsion polymerization of fluoropolymers. The results showed that the surface tension of the emulsion after adding PFSC reached 12 mN/m at a concentration above 0.05%, which is significantly superior to that of perfluorooctanoic acid (PFOA). The study also examined the reaction kinetics, emulsion particle size, and emulsion stability during the emulsion polymerization reaction. The results demonstrated that the fluorinated surfactant exhibits excellent emulsification effects and can serve as an alternative to PFOA. This work presents the synthesis strategy of a new environmentally friendly zwitterionic fluorocarbon surfactant for high-efficiency emulsion polymerization of fluoropolymers.

Similar content being viewed by others

References

Lohmann, R, Letcher, RJ, “The universe of fluorinated polymers and polymeric substances and potential environmental impacts and concerns.” Current Opinion Green Sustain. Chem., 41 100795. https://doi.org/10.1016/j.cogsc.2023.100795 (2023)

Yang, Y, Tan, H, Zhang, J, Shang, F, **ao, F, Li, K, “Surface activity and foam properties of novel Gemini short-chain fluorocarbon and hydrocarbon mixed system in aqueous solutions.” Thermal Sci. Eng. Prog., 38 101628. https://doi.org/10.1016/j.tsep.2022.101628 (2023)

Buck, RC, Korzeniowski, SH, Laganis, E, Adamsky, F, “Identification and classification of commercially relevant per- and poly-fluoroalkyl substances (PFAS).” Integrated Environ. Assess. Manag., 17 (5) 1045–1055. https://doi.org/10.1002/ieam.4450 (2021)

Letcher, RJ, Chu, S, Smyth, SA, “Side-chain fluorinated polymer surfactants in biosolids from wastewater treatment plants.” J. Hazardous Mater., 388 122044. https://doi.org/10.1016/j.jhazmat.2020.122044 (2020)

D’Eon, JC, Mabury, SA, “Production of perfluorinated carboxylic acids (PFCAs) from the biotransformation of polyfluoroalkyl phosphate surfactants (PAPS): Exploring routes of human contamination.” Environ. Sci. Technol., 41 (13) 4799–4805. https://doi.org/10.1021/es070126x (2007)

Johansson, N, Fredriksson, A, Eriksson, P, “Neonatal exposure to perfluorooctane sulfonate (PFOS) and perfluorooctanoic acid (PFOA) causes neurobehavioural defects in adult mice.” NeuroToxicology, 29 (1) 160–169. https://doi.org/10.1016/j.neuro.2007.10.008 (2008)

Zhao, M, Yu, Y, Han, Z, Li, H, “Preparation of a fluorocarbon polymerizable surfactant and its application in emulsion polymerization of fluorine-containing acrylate.” Polymers, 9 606. https://doi.org/10.3390/polym9110606 (2017)

**ao, FS, “Ordered mesoporous silica-based materials templated from fluorocarbon–hydrocarbon surfactant mixtures and semi-fluorinated surfactants.” Curr. Opin. Colloid Interf. Sci., 10 (3) 94–101. https://doi.org/10.1016/j.cocis.2005.05.006 (2005)

Chen, LJ, Wu, FQ, “Structure and properties of novel fluorinated polyacrylate latex prepared with reactive surfactant.” Polymer Sci. Series B, 53 (11) 606–611. https://doi.org/10.1134/S1560090411120013 (2011)

Xu, G, Deng, L, Wen, X, Pi, P, Zheng, D, Cheng, J, Yang, Z, “Synthesis and characterization of fluorine-containing poly-styrene-acrylate latex with core–shell structure using a reactive surfactant.” J. Coat. Technol. Res., 8 (3) 401–407. https://doi.org/10.1007/s11998-010-9308-8 (2011)

Yang, YW, Fang, JQ, Sha, M, Zhang, D, Pan, RM, Jiang, B, “Study on foam extinguishing agents based on hydrocarbon and perfluorinated branched short-chain fluorocarbon surfactants mixed system.” Chem. Papers, 75 (12) 6241–6255. https://doi.org/10.1007/s11696-021-01788-4 (2021)

Kume, G, Gallotti, M, Nunes, G, “Review on anionic/cationic surfactant mixtures.” J. Surf. Detergents, 11 (1) 1–11. https://doi.org/10.1007/s11743-007-1047-1 (2008)

Szymczyk, K, Zdziennicka, A, Jańczuk, B, “Properties of some nonionic fluorocarbon surfactants and their mixtures with hydrocarbon ones.” Adv. Colloid Interf. Sci., 292 102421. https://doi.org/10.1016/j.cis.2021.102421 (2021)

Sarkar, R, Pal, A, Rakshit, A, Saha, B, “Properties and applications of amphoteric surfactant: A concise review.” J. Surf. Detergents, 24 (5) 709–730. https://doi.org/10.1002/jsde.12542 (2021)

Clendennen, SK, Boaz, NW, “Chapter 14 - Betaine amphoteric surfactants—synthesis, properties, and applications.” In: Hayes, DG, Solaiman, DKY, Ashby, RD, (eds.) Biobased Surfactants (Second Edition), pp 447–469. AOCS Press (2019)

Qi, L, Fang, Y, Wang, Z, Ma, N, Jiang, L, Wang, Y, “Synthesis and physicochemical investigation of long alkylchain betaine zwitterionic surfactant.” J. Surf. Detergents, 11 (1) 55–59. https://doi.org/10.1007/s11743-007-1054-2 (2008)

Quan, H, Zhang, X, Lu, H, Huang, Z, “Synthesis and acid solution properties of a novel betaine zwitterionic surfactant.” Central Eur. J. Chem., 10 (5) 1624–1632. https://doi.org/10.2478/s11532-012-0084-4 (2012)

Ren, W, **e, S, Cheng, Y, Zhang, M, Wang, C, Rong, J, Li, Z, “Synthesis and properties of novel betaine fluorocarbon surfactants.” J. Dispersion Sci. Technol., 44 (6) 1000–1009. https://doi.org/10.1080/01932691.2021.1984940 (2023)

Yang, L, Min, R, Wang, G, Wu, Q, Qu, A, Zhuo, C, Wang, Q, Ruan, X, “Evaluation of interfacial, micellar, and foaming properties of the solutions comprising fluorocarbon surfactant, cocamidopropyl betaine, and Gleditsia saponin as fire-extinguishing agents.” Chem. Eng. Sci., 272 118590. https://doi.org/10.1016/j.ces.2023.118590 (2023)

Shen, J, Bai, Y, Tai, X, Wang, W, Wang, G, “Surface activity, spreading, and aggregation behavior of ecofriendly perfluoropolyether amide propyl betaine in aqueous solution.” ACS Sustain. Chem. Eng., 6 (5) 6183–6191. https://doi.org/10.1021/acssuschemeng.7b04895 (2018)

Giles, SL, Snow, AW, Hinnant, KM, Ananth, R, “Modulation of fluorocarbon surfactant diffusion with diethylene glycol butyl ether for improved foam characteristics and fire suppression.” Colloids Surf. A. Physicochem. Eng. Aspects, 579 123660. https://doi.org/10.1016/j.colsurfa.2019.123660 (2019)

Funding

This work was supported by the Science and technology project of Jiangxi Provincial Transportation Department, (Grant No. 2021C0008, Youhua Zhang), (Grant No. 2022H0014, Zewen Zhu), (Grant No. 2022C0007, Zewen Zhu), (Grant No. 2023C0008, Zewen Zhu), the Central Non-Profit Scientific Research Fund for Institutes, (CKSF2023302/CL, Zeyu Fan), (CKSF2019507/CL, CKSF2023317/CL, Wei Han).

Author information

Authors and Affiliations

Contributions

YZ and MZ contributed equally to this work. YZ and MZ involved in conceptualization, data curation, formal analysis, investigation, writing–original draft, supervision and funding acquisition. QL involved in data curation, formal analysis and investigation. JL involved in methodology, formal analysis and investigation. ZZ involved in methodology, formal analysis and investigation. LD involved in data curation and formal analysis. YR involved in data curation and formal analysis. YZ involved in investigation, writing–original draft, and supervision. ZF involved in conceptualization, writing–review and editing and funding acquisition. WH involved in conceptualization, writing–review and editing, funding acquisition and project administration. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, Y., Zhao, M., Luo, Q. et al. Environmentally friendly zwitterionic fluorocarbon surfactant for high-efficiency emulsion polymerization of fluoropolymers. J Coat Technol Res (2024). https://doi.org/10.1007/s11998-024-00943-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11998-024-00943-2