Abstract

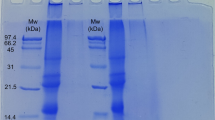

The interaction of polysaccharide and protein can improve the emulsification and gelation properties of emulsion gel, which is a good substrate for 3D printing food. Whey protein isolate (WPI) emulsion gels with guar gum (GG), locust bean gum (LBG), xanthan gum (XG), and gum arabic (GA) concentrations of 1%, 3%, 5%, 7%, and 9% were investigated for 3D printing β-carotene-rich food. The effect of different polysaccharide concentrations on the rheological properties, 3D printing performances (printability, printing accuracy, and printing stability), and moisture distribution characteristics of emulsion gels were analyzed. The results showed that WPI emulsion gels with the addition of polysaccharides had shear-thinning behavior and exhibited elastic property. WPI emulsion gels added with polysaccharides of more than 5% had the higher transient elasticity and viscosity, which exhibited the higher deformation resistance. Water holding capacity and gel strength of WPI emulsion gels increased with the increase of polysaccharide concentration, and WPI emulsion gels added with GG and LBG showed the larger gel strength values. Water trapped in the gel network dominated in WPI emulsion gels, T21, T22, and T23 values decreased with the increases of polysaccharide concentration. The results showed that 7% of GG, LBG, and GA could improve the 3D printing performance and significantly increased the printing accuracy and stability of WPI emulsion gels.

Similar content being viewed by others

Data Availability

No datasets were generated or analysed during the current study.

References

Alakhrash, F., Anyanwu, U., & Tahergorabi, R. (2016). Physicochemical properties of Alaska pollock (Theragra chalcograma) surimi gels with oat bran. LWT-Food Science and Technology, 66, 41–47. https://doi.org/10.1016/j.lwt.2015.10.015

Barak, K., & Mudgil, D. (2014). Locust bean gum: Processing, properties and food applications—A review. International Journal of Biological Macromolecules, 66, 74–80. https://doi.org/10.1016/j.ijbiomac.2014.02.017

Bi, C. H., Li, D., Wang, L. J., & Adhikari, B. (2017). Effect of LBG on the gel properties of acid-induced SPI gels. LWT-Food Science and Technology, 75, 1–8. https://doi.org/10.1016/j.lwt.2016.08.028

Chang, Y. Y., Li, D., Wang, L. J., Bi, C. H., & Adhikari, B. (2014). Effect of gums on the rheological characteristics and microstructure of acid-induced SPI--gum mixed gels. Carbohydrate Polymers, 108, 183-191. http://dx.doi.org/10.1016/j.carbpol.2014.02.089

Chen, C., Zhang, M., Guo, C. F., & Chen, H. Z. (2021). 4D printing of lotus root powder gel: Color change induced by microwave. International Journal of Biological Macromolecules, 68, 102605. https://doi.org/10.1016/j.ifset.2021.102605

Cortez-Trejo, M. C., Gaytán-Martínez, M., Reyes-Vega, M. L., & Mendoza, S. (2021). Protein-gum-based gels: Effect of gum addition on microstructure, rheological properties, and water retention capacity. Trend in Food Science & Technology, 116, 303–317. https://doi.org/10.1016/j.tifs.2021.07.030

Du, Y. M., Zhang, M., & Chen, H. Z. (2021). Effect of whey protein on the 3D printing performance of konjac hybrid gel. LWT-Food Science and Technology, 140, 110716. https://doi.org/10.1016/j.lwt.2020.110716

García-Ochoa, F., Santos, V. E., Casas, J. A., & Gómez, E. (2000). Xanthan gum: Production, recovery, and properties. Biotechnology Advances, 18(7), 549–579. https://doi.org/10.1016/S0734-9750(00)00050-1

Geng, M. J., Wang, Z. K., Qin, L., Taha, A., Du, L. X., & Xu, X. Y. (2022). Effect of ultrasound and coagulant types on properties of β-carotene bulk emulsion gels stabilized by soy protein. Food Hydrocolloids, 123, 107146. https://doi.org/10.1016/j.foodhyd.2021.107146

Guo, C. F., Zhang, M., & Devahastin, S. (2021). Color/aroma changes of 3D-printed buckwheat dough with yellow flesh peach as triggered by microwave heating of gelatin-gum Arabic complex coacervates. Food Hydrocolloids, 112, 106358. https://doi.org/10.1016/j.foodhyd.2020.106358

Hou, J. J., Guo, J., Wang, J. M., & Yang, X. Q. (2016). Effect of interfacial composition and crumbliness on aroma release in soy protein/sugar beet pectin mixed emulsion gels. Journal of the Science of Food and Agriculture, 96(13), 4449–4456. https://doi.org/10.1002/jsfa.7656

Huang, C. Y., Blecker, C., Wei, X. R., **e, X. R., Li, S. B., Li, C., et al. (2024). Effects of different plant polysaccharides as fat substitutes on the gel properties, microstructure and digestion characteristics of myofibrillar protein. Food Hydrocolloids, 150, 109717. https://doi.org/10.1016/j.foodhyd.2023.109717

Huang, Y. W., Zhang, M., & Pattarapon, P. (2022). Reducing freeze-thaw drip loss of mixed vegetable gel by 3D printing porosity. International Journal of Biological Macromolecules, 75, 102893. https://doi.org/10.1016/j.ifset.2021.102893

Koç, M., Koç, B., Susyal, G., Yilmazer, M. S., Bağdatlıoğlu, N., & Kaymak-Ertekin, F. (2011). Improving functionality of whole egg powder by the addition of gelatine, lactose, and pullulan. Journal of Food Engineering, 76(9), 508–515. https://doi.org/10.1111/j.1750-3841.2011.02420.x

Lei, Y. C., Zhao, X., Li, D., Wang, L. J., & Wang, Y. (2022). Effects of κ-carrageenan and guar gum on the rheological properties and microstructure of phycocyanin gel. Foods, 11(5), 734. https://doi.org/10.3390/foods11050734

Li, X. P., Fan, L. P., Liu, Y. F., & Li, J. W. (2021). New insights into food O/W emulsion gels: Strategies of reinforcing mechanical properties and outlook of being applied to food 3D printing. Food Science and Nutrition, 1965953. https://doi.org/10.1080/10408398.2021.1965953

Liu, Z. B., Bhandari, B., Prakash, S., Mantihal, S., & Zhang, M. (2019). Linking rheology and printability of a multicomponent gel system of carrageenan-xanthan-starch in extrusion based additive manufacturing. Food Hydrocolloids, 87, 413–424. https://doi.org/10.1016/j.foodhyd.2018.08.026

Liu, Z. B., Dick, A., Prakash, S., Bhandari, B., & Zhang, M. (2020a). Texture modification of 3D printed air-fried potato snack by varying its internal structure with the potential to reduce oil content. Food and Bioprocess Technology, 13(3), 564–576. https://doi.org/10.1007/s11947-020-02408-x

Liu, Z. B., Zhang, M., & Bhandari, B. (2020b). Incorporation of probiotics (Bifidobacterium animalis subsp. Lactis) into 3D printed mashed potatoes: Effects of variables on the viability. Food Research International, 128, 108795. https://doi.org/10.1016/j.foodres.2019.108795

Liu, Z. B., Zhang, M., Bhandari, B., & Wang, Y. C. (2017). 3D printing: Printing precision and application in food sector. Trend in Food Science & Technology, 69(8), 83–94. https://doi.org/10.1016/j.tifs.2017.08.018

Liu, Z. B., Zhang, M., Bhandari, B., & Yang, C. H. (2018). Impact of rheological properties of mashed potatoes on 3D printing. Journal of Food Engineering, 220, 76–82. https://doi.org/10.1016/j.jfoodeng.2017.04.017

Niu, F. G., Niu, D. B., Zhang, H. J., Chang, C. H., Gu, L. P., Su, Y. J., et al. (2016). Ovalbumin/gum arabic-stabilized emulsion: Rheology, emulsion characteristics, and Raman spectroscopic study. Food Hydrocolloids, 52, 607–614. https://doi.org/10.1016/j.foodhyd.2015.08.010

Renard, D., Velde, F. V. D., & Visschers, R. W. (2006). The gap between food gel structure, texture and perception. Food Hydrocolloids, 20(4), 423–431. https://doi.org/10.1016/j.foodhyd.2005.10.014

Sadahira, M. S., Lopes, F. C. R., Rodrigues, M., & Netto, F. M. (2014). Influence of protein-pectin electrostatic interaction on the foam stability mechanism. Carbohydrate Polymers, 104, 55–61. https://doi.org/10.1016/j.carbpol.2013.11.070

Shahbazi, M., Jäger, H., & Ettelaie, R. (2021a). Application of pickering emulsions in 3D printing of personalized nutrition. Part I: Development of reduced-fat printable casein-based ink. Colloids and Surfaces A: Physicochemical and Engineering Aspects., 622, 126641. https://doi.org/10.1016/j.colsurfa.2021.126641

Shahbazi, M., Jäger, H., Ettelaie, R., & Chen, J. S. (2021b). Construction of 3D printed reduced-fat meat analogue by emulsion gels. Part I: Flow behavior, thixotropic feature, and network structure of soy protein-based inks. Colloid Surface A: Physicochemical and Engineering Aspects, 622, 126641. https://doi.org/10.1016/j.foodhyd.2021.106967

Sharma, G., Sharma, S., Kumar, A., Al-Muhtaseb, A. H., Naushad, M., Ghfar, A. A., et al. (2018). Guar gum and its composites as potential materials for diverse applications: A review. Carbohydrate Polymers, 199, 534–545. https://doi.org/10.1016/j.carbpol.2018.07.053

Wang, L., Zhang, M., Bhandari, B., & Yang, C. H. (2018a). Investigation on fish surimi gel as promising food material for 3D printing. Journal of Food Engineering, 220, 101–108. https://doi.org/10.1016/j.jfoodeng.2017.02.029

Wang, W. J., Shen, M. Y., Liu, S. C., Jiang, L., Song, Q. Q., & **e, J. H. (2018b). Gel properties and interactions of Mesona blumes polysaccharide-soy protein isolates mixed gel: The effect of salt addition. Carbohydrate Polymers, 192, 193–210. https://doi.org/10.1016/j.carbpol.2018.03.064

Wang, X., Wang, L. M., Yang, K., Wu, D., Ma, J., & Wang, S. J. (2021). Radio frequency heating improves water retention of pork myofibrillar protein gel: An analysis from water distribution and structure. Food Chemistry, 350, 129265. https://doi.org/10.1016/j.foodchem.2021.129265

Xu, K. Q., Wu, C. E., Fan, G. J., Kou, X. H., Li, X. J., & Li, T. T. (2023a). Rheological properties, gel properties and 3D printing performance of soy protein isolate gel inks added with different types of apricot polysaccharides. International Journal of Biological Macromolecules, 242, 124624. https://doi.org/10.1016/j.ijbiomac.2023.124624

Xu, L., Xu, G. Y., Liu, T., Chen, Y. J., & Gong, H. J. (2013). The comparison of rheological properties of aqueous welan gum and xanthan gum solutions. Carbohydrate Polymers, 92(1), 516–522. https://doi.org/10.1016/j.carbpol.2012.09.082

Xu, W., Ning, Y. L., Wang, M. Y., Zhang, S., Sun, H. M., Yin, Y. P., et al. (2023b). Construction of astaxanthin loaded Pickering emulsions gel stabilized by xanthan gum/lysozyme nanoparticles with konjac glucomannan from structure, protection and gastrointestinal digestion perspective. International Journal of Biological Macromolecules, 252(1), 126421. https://doi.org/10.1016/j.ijbiomac.2023.126421

Yang, F., Zhang, M., Bhandari, B., & Liu, Y. P. (2018). Investigation on lemon juice gel as food material for 3D printing and optimization of printing parameters. LWT-Food Science and Technology, 87(8), 67–76. https://doi.org/10.1016/j.lwt.2017.08.054

Yu, H. Z., Chi, S. Y., Li, D., Wang, L. J., & Wang, Y. (2022a). Effect of gums on the multi-scale characteristics and 3D printing performance of potato starch gel. Innovative Food Science and Emerging Technologies, 80, 103102. https://doi.org/10.1016/j.ifset.2022.103102

Yu, J., Li, D., Wang, L. J., & Wang, Y. (2022b). Improving freeze-thaw stability and 3D printing performance of soy protein isolate emulsion gel inks by guar & xanthan gums. Food Hydrocolloids, 135, 108293. https://doi.org/10.1016/j.foodhyd.2022.108293

Zhang, H. X., Fan, Q., Li, D., Chen, X., & Liang, L. (2019). Impact of gum Arabic on the partition and stability of resveratrol in sunflower oil emulsions stabilized by whey protein isolate. Colloids and Surfaces B-Biointerfaces, 181, 749–755. https://doi.org/10.1016/j.colsurfb.2019.06.034

Zhang, X., Chen, X., Gong, Y. H., Li, Z. Y., Guo, Y. F., Yu, D. Y., et al. (2021a). Emulsion gels stabilized by soybean protein isolate and pectin: Effects of high intensity ultrasound on the gel properties, stability and β-carotene digestive characteristics. Ultrasonics Sonochemistry, 79, 105756. https://doi.org/10.1016/j.ultsonch.2021.105756

Zhang, Y. Y., Gu, Z. B., Zhu, L., & Hong, Y. (2018). Comparative study on the interaction between native corn starch and different hydrocolloids during gelatinization. International Journal of Biological Macromolecules, 116, 136–143. https://doi.org/10.1016/j.ijbiomac.2018.05.011

Zhang, Z. Q., Chen, W. C., Zhou, X., Huang, T. T., Dong, X. Y., Yang, C., et al. (2021c). Astaxanthin-loaded emulsion gels stabilized by Maillard reaction products of whey protein and flaxseed gum: Physicochemical characterization and in vitro digestibility. Food Research International, 144, 110321. https://doi.org/10.1016/j.foodres.2021.110321

Zhang, Z., Hao, G. Y., Liu, C., Fu, J. Q., Hu, D., Rong, J. H., et al. (2021b). Recent progress in the preparation, chemical interactions and applications of biocompatible polysaccharide-protein nanogel carriers. Food Research International, 147, 110564. https://doi.org/10.1016/j.foodres.2021.110564

Zhao, H. B., Chen, J., Hemar, Y., & Cui, B. (2020). Improvement of the rheological and textural properties of calcium sulfate-induced soy protein isolate gels by the incorporation of different polysaccharides. Food Chemistry, 310, 125983. https://doi.org/10.1016/j.foodchem.2019.125983

Zhu, S. C., Stieger, M. A., Goot, A. J., & Schutyser, M. A. I. (2019). Extrusion-based 3D printing of food pastes: Correlating rheological properties with printing behaviour. Innovative Food Science and Emerging Technologies, 58, 102214. https://doi.org/10.1016/j.ifset.2019.102214

Zhuang, X. B., Han, M. Y., Bai, Y., Liu, Y. F., **ng, L. J., Xu, X. L., et al. (2018). Insight into the mechanism of myofibrillar protein gel improved by insoluble dietary fiber. Food Hydrocolloids, 74, 219–226. https://doi.org/10.1016/j.foodhyd.2017.08.015

Funding

We acknowledge the financial support by the National Nature Science Foundation of China (No. 32102001) and the National Key R&D Program of China (No. 2022YFF1102000), which have enabled us to carry out this study.

Author information

Authors and Affiliations

Contributions

Ming Li: conceptualization, methodology, software, validation, formal analysis, writing; Lei Feng: investigation, formal analysis, funding acquisition; Zhuqing Dai: validation; Da**g Li: conceptualization, supervision, validation; Zhongyuan Zhang: validation; Cunshan Zhou: validation; Dongxing Yu: validation.

Corresponding authors

Ethics declarations

Competing Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, M., Feng, L., Dai, Z. et al. Improvement of 3D Printing Performance of Whey Protein Isolate Emulsion Gels by Regulating Rheological Properties: Effect of Polysaccharides Incorporation. Food Bioprocess Technol (2024). https://doi.org/10.1007/s11947-024-03488-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11947-024-03488-9