Abstract

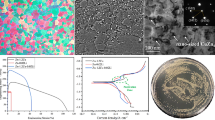

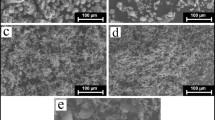

The effect of variable rate nonisothermal aging (VR-NIA) on the properties and microstructure of Al-Zn-Mg-Cu alloy was studied through testing, such as hardness, friction and wear, intergranular corrosion (IGC), electrochemical corrosion and transmission electron microscopy (TEM) observation. The results showed that the comprehensive properties of Al-Zn-Mg-Cu alloy were significantly improved, and the microstructure morphology was well optimized after a new four stage VR-NIA treatment. After the variable speed process of 200–100–160°C, the hardness of the alloy reaches the highest value. The 3D friction and wear topography show that the wear depth of the specimen is the lowest and the wear resistance is the best. The matrix precipitate phase (MPts) had the smallest average size, the highest volume fraction and the strongest precipitation enhancement. When VR-NIA is completed, the intergranular corrosion depth of the H200 specimen is the smallest, the pitting pits are the fewest, and the corrosion rate is the slowest. Grain boundary precipitate phase (GBP) is coarse, the size and distance increase, it is intermittently distributed, and the corrosion does not progress easily. The corrosion resistance of the alloy is improved because of the increase in the width of the precipitate free zone (PFZ).

Similar content being viewed by others

References

B. Zhou, B. Liu, S.G. Zhang, R. Lin, Y. Jiang, and X.Y. Lan, J. Alloys Compd. 879, 160407 (2021).

W.J. Zhang, R.M. Su, G.L. Li, and Y.D. Qu, J. Alloys Compd. 960, 170953 (2023).

R.M. Su, T. Liu, Y.D. Qu, G. Bai, and R.D. Li, J. Mater. Eng. Perform. 28(4), 2212 (2019).

X.Y. Peng, W.S. Su, D. **ao, and G.F. Xu, JOM 70(6), 993 (2018).

Y.Z. Wang, R.M. Su, G.L. Li, and Y.D. Qu, Mater. Today. Commun. 37, 107571 (2023).

Y.Z. Wang, R.M. Su, M.L. **, and G.L. Li, JOM 76(4), 1951 (2024).

J.I. Rojas and D. Crespo, Metall. Mater. Trans. A 43, 4633 (2012).

R.M. Su, Y.D. Qu, R.D. Li, C. Tian, and S.N. Nie, Mater. Sci. Forum 993, 146 (2020).

D. James, T. Staley, US Patent 20070267113 Al (2007).

Y.F. Wu, Y.M. Zhong, W. Xu, and X.Y. Li, Mater. Lett. 315, 131930 (2022).

G.Y. Zheng, X. Luo, Z.D. Kou, B. Huang, and Y.Q. Yang, Mater. Charact. 194, 112418 (2022).

J.T. Jiang, W.Q. **ao, L. Yang, W.Z. Shao, S.J. Yuan, and L. Zhen, Mater. Sci. Eng. A 605, 167 (2014).

Y. Liu, D.M. Jiang, B.Q. Li, W.S. Yang, and J. Hu, Mater. Des. 57, 79 (2014).

B. Ke, L. Ye, Y. Zhang, J. Tang, S. Liu, X. Liu, Y. Dong, and P. Wang, J. Alloys Compd. 890, 161933 (2022).

H. Zhao, L.Y. Ye, Q.S. Cheng, Y. Kang, and W.J. Zhang, Mater. Charact. 197, 112715 (2023).

C. Xu, J. Zhao, A. Guo, H. Li, G. Dai, and X. Zhang, J. Mater. Process. Technol. 249, 167 (2017).

S. Yuan, M.D. Wu, X. Yin, Z.Y. Li, Y. Huang, and D.H. **ao, Mater. Charact. 207, 113491 (2024).

J.G. Zhao, Z.Y. Liu, S. Bai, D.P. Zeng, L. Luo, and J. Wang, J. Alloys Compd. 829, 154469 (2020).

K.N. Wang, R.M. Su, S.Y. Ma, Y.D. Qu, and R.D. Li, J. Mater. Eng. Perform. 29, 3297 (2020).

Y.X. Jia, R.M. Su, L. Wang, G.L. Li, Y.D. Qu, and R.D. Li, Trans. Indian Inst. Met. 76, 741 (2022).

R.M. Su, Y.X. Jia, G.L. Li, Y.D. Qu, and R.D. Li, J. Alloys Compd. 947, 169578 (2023).

C. Guo, H.T. Zhang, Z.B. Wu, D.T. Wang, B.M. Li, and J.Z. Cui, Mater. Charact. 147, 84 (2019).

X. Sauvage, F. Cuvilly, A. Russell, and K. Edalati, Mater. Sci. Eng. A 798, 140108 (2020).

W.F. Xu, H.J. Lu, X.H. Li, M. Wang, J. Ma, and Y.X. Luo, Mater. Des. 212, 110297 (2021).

Y.P. **ao, Q.L. Pan, W.B. Li, X.Y. Liu, and Y.B. He, Mater. Corros. 63, 421 (2012).

S.Y. Chen, K.H. Chen, G.S. Peng, et al., Mater. Des. 35, 93 (2012).

F.Q. Guo, S.W. Duan, Y.Z. Pan, D.T. Wu, K.J. Matsuda, T. Wang, and Y. Zou, J. Mater. Res. Technol. 23, 5807 (2023).

T.A. Pan, Y.J. Lian, Y.C. Tzeng, H.Y. Bor, and S.L. Lee, JOM 74(10), 3877 (2022).

S.Y. Ma, R.M. Su, G.L. Li, Y.D. Qu, and R.D. Li, J. Phys. Chem. Solids 167, 110747 (2022).

R.M. Su, S.Y. Ma, K.N. Wang, G.L. Li, Y.D. Qu, and R.D. Li, Met. Mater. Int. 28, 862 (2022).

P.K. Rout, M.M. Ghosh, and K.S. Ghosh, Mater. Sci. Eng. A 604, 156 (2014).

P. Zhang, L. Bao, S.X. Rao, J.J. Wu, Y.B. Li, and C.Y. **ong, Rare. Met. Mater. Eng. 52(12), 4099 (2023).

P. Zhang, X.S. Zhao, and S.X. Rao, Rare. Met. Mater. Eng. 52(05), 1573 (2023).

R.M. Su, Y.D. Qu, and R.D. Li, J. Mater. Eng. Perform. 23, 3842 (2014).

G. Sha and A. Cerezo, Acta Mater. 52, 4503 (2004).

J.L. Fu, S.X. Wang, and K.K. Wang, J. Mater. Sci. 53, 9790 (2018).

X.Y. Peng, Y. Li, Q. Guo, and G.F. Xu, JOM 70(11), 2692 (2018).

C.L. Tang, B.H. Luo, and Z.H. Bai, Mater. Sci. Eng. A 830, 142315 (2022).

X. Sheng, Y. Yang, Y. Cheng, J. Li, W. Wu, Y. Liu, K. Li, Y. Zhao, and G. He, J. Alloys Compd. 845, 156198 (2020).

T. Ramgopal, P.I. Gouma, and G.S. Frankel, Corrosion 58, 687 (2002).

Y.J. Shi, Q.L. Pan, M.J. Li, X. Huang, and B. Li, J. Alloys Compd. 612, 42 (2014).

Z. Li, L. Chen, J. Tang, G. Zhao, and C. Zhang, J. Alloys Compd. 848, 156561 (2020).

K. Wen, B. **ong, Y. Zhang, Z. Li, X. Li, S. Huang, L. Yan, H. Yan, and H. Liu, Met. Mater. Int. 24, 537 (2018).

S.D. Liu, B. Chen, C.B. Li, Y. Dai, Y.L. Deng, and X.M. Zhang, Corros. Sci. 91, 203 (2015).

Acknowledgements

This research was supported by the National Nature Science Foundation of China (52204394).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Consent for publication

All co-authors agree to publish in the JOM.

Consent to participate

All co-authors agree to participate in this journal.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, Y., Shi, L., Su, R. et al. Effect of Variable Rate Non-isothermal Aging on the Microstructure and Properties of Al-Zn-Mg-Cu Alloy. JOM (2024). https://doi.org/10.1007/s11837-024-06671-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11837-024-06671-7