Abstract

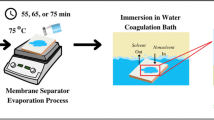

This study delves into the production and evaluation of cellulose acetate (CA) separators with a focus on their application in lithium-ion batteries. The primary objective is to optimize battery performance by customizing separator characteristics through the integration of diverse additives and water-pressure treatments. Three distinct categories of additives were investigated, which include hydrated metal nitrates, organic compounds, and metal compounds. The impact of these additives on pore generation and porosity was comprehensively analyzed. Among the hydrated metal nitrates, Cd(NO3)2·4H2O emerged as a highly effective plasticizer in comparison to Ni(NO3)2 and Mg(NO3)2. This superiority can be attributed to the relatively larger ionic radius of cadmium (Cd) among these three elements, facilitating the dissociation of Cd ions into cations and counteranions. Within the realm of organic compounds, glycerin proved to be more efficient in inducing the formation of abundant pores in CA polymers when compared to propylene glycol and lactic acid. As for the metal compounds, they exhibited notable effectiveness in preparing porous CA polymers for battery separators. However, these materials tend to yield larger pore sizes, potentially due to their higher dissociation energy. The findings of this investigation underscore the feasibility of employing a range of additives to craft porous cellulose acetate separators. These resulting separators exhibit varying degrees of porosity, positioning them as promising candidates for enhancing lithium-ion battery performance. Consequently, this review contributes to the ongoing advancement of cutting-edge battery technologies by tailoring separator materials to specific requirements.

Similar content being viewed by others

References

C. Song, C. Gao, Q. Peng, M.E. Gibril, X. Wang, S. Wang, F. Kong, A novel high-performance electrospun of polyimide/lignin nanofibers with unique electrochemical properties and its application as lithium-ion batteries separators. Int. J. Biol. Macromol. 246, 125668 (2023)

M. Makki, G. Ayoub, C.W. Lee, C. Bae, X. Colin, Effect of battery fast cyclic charging on the mechanical and fracture behavior of the lithium-ion battery separator. Polym. Degrad. Stab. 216, 110469 (2023)

H. Chen, B. Ren, Y. Wang, M. Liu, H. He, L. Chai, J. Jia, X. Yang, J. Chen, B. Li, The fabrication of high-performance α-Al2O3 coated PE separator for lithium-ion batteries based on multiple hydrogen bonds. Electrochim. Acta. 465, 142985 (2023)

M. Bhar, U. Bhattacharjee, K. Yalamanchili, S.K. Martha, Effective upcycling of waste separator and boosting the electrochemical performance of recycled graphite anode for lithium-ion batteries. J. Power Sources 580, 233403 (2023)

W. Miao, J. Wang, G. Li, S. Liu, X. Luo, Superior thermal stability of PVA/cellulose composite membranes for lithium-ion battery separators prepared by impregnation method with noncovalent cross-linking of intermolecular multiple hydrogen-bonds. J. Energy Storage 66, 107353 (2023)

R. Yang, G. Yu, Z. Wu, T. Lu, T. Hu, F. Liu, H. Zhao, Aging of lithium-ion battery separators during battery cycling. J. Energy Storage 63, 107107 (2023)

Y. Liu, S. Lv, M. Zhang, J. He, P. Ni, UV-photopolymerized cellulose acetate-acrylate membranes for lithium-ion battery separator. Colloids Surf. A 667, 131359 (2023)

Y. Sun, J. Wang, J.M. Prausnitz, Interfacial properties between ionic-liquid-based electrolytes and lithium-ion-battery separator. AIChE J. 67, e17208 (2021)

H. Guo, M. Li, F. Li, Q. Zhu, Y. Zhao, F. Wang, Z. Qin, Enhanced wettability of a PTFE porous membrane for a high-temperature stable lithium-ion battery separator. Chem. Eng. Technol. 45, 73 (2022)

J. Lee, J. Yoon, J. Jeon et al., Electrospun PVDF-HFP/PAN bicomponent nanofibers as separators in lithium-ion batteries with high thermal stability and electrolyte wettability. Korean J. Chem. Eng. 40, 1901 (2023)

J. Shin, Y. Kim, J.M. Lee, Feature construction for on-board early prediction of electric vehicle battery cycle life. Korean J. Chem. Eng. 40, 1850 (2023)

S. Han, M. Park, S. Huh et al., The electrochemical performance of lotus-root shaped meso-/macroporous TiO2 anode for lithium-ion battery. Korean J. Chem. Eng. 40, 1234 (2023)

I. Choi, B. Gendensuren, J. Lee et al., Cyanoethyl-guar gum as an effective polymer binder for lithium titanate electrode of the lithium-ion battery. Korean J. Chem. Eng. 40, 802 (2023)

J.H. Choi, J. Hwang, T.J. Embleton et al., Selective outer surface modification of polycrystalline Ni-rich cathode for sulfide all-solid-state lithium-ion battery. Korean J. Chem. Eng. 40, 548 (2023)

M. Nazerian, N. Bahaloo-Horeh, S.M. Mousavi, Enhanced bioleaching of valuable metals from spent lithium-ion batteries using ultrasonic treatment. Korean J. Chem. Eng. 40, 584 (2023)

W.G. Lee, D.H. Kim, W.C. Jeon, S.K. Kwak, S.J. Kang, S.W. Kang, Facile control of nanoporosity in cellulose acetate using nickel(II) nitrate additive with water pressure treatment for highly efficient battery gel separators. Sci. Rep. 7, 1287 (2017)

W.G. Lee, S.W. Kang, Eco-friendly process for facile pore control in thermally stable cellulose acetate utilizing zinc(II) nitrate for water-treatment. J. Ind. Eng. Chem. 81, 88–92 (2020)

W.G. Lee, Y. Cho, S.W. Kang, Effect of ionic radius in metal nitrate on pore generation of cellulose acetate in polymer nanocomposite. Polymers 12, 981 (2020)

W.G. Lee, Y. Cho, S.W. Kang, Effect of ionic radius in metal nitrate on pore generation of cellulose acetate in polymer nanocomposite. Polymers 12, 981–989 (2020)

S.H. Hong, Y. Cho, S.W. Kang, Highly porous and thermally stable cellulose acetate to utilize hydrated glycerin. J. Ind. Eng. Chem. 91, 79–84 (2020)

S.H. Hong, Y. Cho, S.W. Kang, Formation of water-channel by propylene glycol into polymer for porous materials. Membranes 11, 881 (2021)

S.H. Kim, S.W. Kang, Preparation of highly stable cellulose separator by incorporation of lactic acid. Cellulose 28(15), 10055–10063 (2021)

S.H. Kim, S.W. Kang, Interconnected channels through polypropylene and cellulose acetate by utilizing lactic acid for stable separators. Chem. Commun. 57, 8965–8968 (2021)

H.J. Lee, Y. Cho, S.W. Kang, Development of low-cost process for pore generation in cellulose acetate by utilizing calcium salts. J. Ind. Eng. Chem. 94, 419–424 (2021)

H.J. Lee, S.W. Kang, Improvement of stability for cellulose polymer by calcium oxide for application to porous materials. Cellulose 29, 8319–8327 (2022)

H.J. Lee, Y. Cho, S.W. Kang, Low-cost process to utilize sodium salts for porous cellulose materials. J. Ind. Eng. Chem. 113, 368–372 (2022)

H.J. Lee, S.W. Kang, Cellulose acetate containing CaO coated on polypropylene for enhanced thermal stability of separator. Chem. Commun. 57, 4388–4391 (2021)

X. **e, L. Sheng, C. Arbizzani, B. Gao, X. Gao, L. Yang, Y. Bai, H. Dong, G. Liu, T. Wang, X. Huang, J. He, Multi-functional groups decorated composite nanofiber separator with excellent chemical stability in ester-based electrolyte for enhancing the lithium-ion transport. J. Power Sources 555, 232431 (2023)

C. Cheng, R. Yang, Y. Wang, D. Fu, J. Sheng, X. Guo, A bacterial cellulose-based separator with tunable pore size for lithium-ion batteries. Carbohydr. Polym. 304, 120489 (2023)

Q. Zhao, L. Ma, Y. Xu, X. Wu, S. Jiang, Q. Zheng, G. Hong, B. He, C. Li, W. Cen, W. Zhou, Y. Meng, D. **ao, An upgraded polymeric composite with interparticle chemical bonding microstructure toward lithium-ion battery separators with enhanced safety and electrochemical performances. J. Energy Chem. 84, 402–413 (2023)

J. **ng, W. Fan, J. Li, Z. Wang, Z. Wei, Y. Zhao, Orientation gradient architecture of nanofibrous separator towards mechanical enhancement and ion transport acceleration for lithium-ion batteries. Electrochim. Acta. 441, 141794 (2023)

Acknowledgements

This study was supported by the University Innovation Support Project through Sangmyung University in 2023.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kang, S.W., Cho, Y. Strategy to Increase the Efficiency of Battery Systems Equipped with Cellulose-Based Separators. Korean J. Chem. Eng. 41, 403–409 (2024). https://doi.org/10.1007/s11814-024-00098-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-024-00098-1