Abstract

The utilization of Açaí residues holds significant economic and environmental importance in Brazil. The drying technique is an alternative for preserving Açaí kernel from fresh fruit processing. This study employed diffusive, empirical, and Artificial Neural Network (ANN) models to simulate the convective drying of ground Açaí kernel, with air temperature and air velocity ranging from 80 to 120 °C and 0.5 and 0.9 m/s, respectively. To assess the robustness of the models, a validation step using experimental conditions distinct from those used in the training dataset was carried out. The impact of cross-validation on the generalization capacity of the ANN-based models was investigated. Furthermore, input importance techniques were employed to gain insights into the functioning of the ANN models. The diffusivity coefficient exhibited values between 9.22 × 10−10 and 2.26 × 10−9 m2/s. The Page was the best empirical model (R2 = 0.9918). For the ANN-based models, five pairs of input–output variables were considered and produced models with comparable or superior performance compared to the diffusive and empirical models. The best ANN model achieved an R2 > 0.9999. The cross-validation technique only enhanced the generalization capacity of ANN-based models that used delayed variables in the input instead of the drying time. Additionally, the feature importance analysis revealed that the best ANN model effectively captured the essential drying aspects: air temperature and velocity effects, the falling rate period, and higher drying rates at the beginning of the experiments.

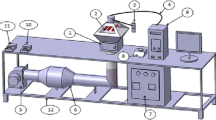

Graphical abstract

Similar content being viewed by others

Abbreviations

- ANN:

-

Artificial neural network

- ANOVA:

-

Analysis of variance

- MC:

-

Moisture content

- SHAP:

-

Shapley additive explanations

- \(a,b,{b}_{1},{b}_{2},{b}_{3},{k}_{o},n\) :

-

Empirical coefficients

- \({B}^{\langle 1\rangle }\) :

-

Bias of the hidden layer

- \({B}^{\langle 2\rangle }\) :

-

Bias of the output layer

- \({D}_{\mathrm{eff}}\) :

-

Effective moisture diffusivity (\({\mathrm{m}}^{2}/\mathrm{s})\)

- \({D}_{o}\) :

-

Pre-exponential factor (\({\mathrm{m}}^{2}/\mathrm{s}\))

- \({E}_{a}\) :

-

Activation energy (kJ/mol)

- \({f}_{\langle 1\rangle }(\bullet )\) :

-

Activation function in the hidden layer

- \({f}_{\langle 2\rangle }(\bullet )\) :

-

Activation function in the output layer

- \(L\) :

-

Thickness of the sample (\(\mathrm{m}\))

- \(m(t)\) :

-

Mass of the material at a specific time t (kg)

- \({m}_{d}\) :

-

Mass of the dry solids (kg)

- \({M}_{\mathrm{eq}}\) :

-

Equilibrium moisture content (\({\mathrm{kg}}_{\mathrm{water}}/{\mathrm{kg}}_{\mathrm{dry matter}})\)

- \({M}_{o}\) :

-

Initial moisture content (\({\mathrm{kg}}_{\mathrm{water}}/{\mathrm{kg}}_{\mathrm{dry matter}})\)

- \({M}_{t}\) :

-

Moisture content at specific time t (\({\mathrm{kg}}_{\mathrm{water}}/{\mathrm{kg}}_{\mathrm{dry matter}}\))

- \(\mathrm{MR}(t)\) :

-

Moisture ratio at specific time \(t\)

- \(N\) :

-

Number of observations

- \({N}_{z}\) :

-

Number of model constants

- \(p\) :

-

Number of neurons

- \(q\) :

-

Number of input variables

- \({R}_{g}\) :

-

Universal gas constant (kJ·mol−1 K−1)

- \({\mathrm{RI}}_{j}\) :

-

Relative importance of input \(j\)

- \(\mathrm{RMSE}\) :

-

Root mean squared error

- \({R}^{2}\) :

-

Coefficient of determination

- \(t\) :

-

Drying time (\(\mathrm{s}\))

- \(T\) :

-

Air temperature (°C)

- \(V\) :

-

Air velocity (\(\mathrm{m}/\mathrm{s}\))

- \({W}^{\langle 1\rangle }\) :

-

Weight matrix between input and hidden layers

- \({W}^{\langle 2\rangle }\) :

-

Weight matrix between hidden and output layers

- \(x\) :

-

Artificial Neural Network inputs

- \({y}_{i}\) :

-

i-th Experimental value

- \({\widehat{y}}_{i}\) :

-

i-th Model output value

- \(z\) :

-

Diffusion path (\(\mathrm{m}\))

- \({\chi }^{2}\) :

-

Reduced chi-squared

References

Abbaspour-Gilandeh Y, Kaveh M, Jahanbakhshi A (2019) The effect of microwave and convective dryer with ultrasound pretreatment on drying and quality properties of walnut kernel. J Food Process Preserv 43(11):e14178. https://doi.org/10.1111/jfpp.14178

Abbaspour-Gilandeh Y, Jahanbakhshi A, Kaveh M (2020) Prediction kinetic, energy and exergy of quince under hot air dryer using ANNs and ANFIS. Food Sci Nutr 8(1):594–611. https://doi.org/10.1002/fsn3.1347

Azevedo AVS, Ribeiro MVS, Fonseca MTS, Gusmão TAS, Gusmão RP (2015) Avaliação física, físico-química e sensorial de cookies enriquecidos com farinha de açaí. Rev Verde de Agroecol e Desenvolv Sustent 10(4):49–54

Bannoud MAl, Martins TD, dos Santos BF (2022) Control of a closed dry grinding circuit with ball mills using predictive control based on neural networks. Digit Chem Eng 5:100064. https://doi.org/10.1016/j.dche.2022.100064

Barbosa Neto AM, Lima JO, Marques LG, Prado MM (2015) Secagem infravermelho de caroços de açaí para a obtenção de biomassa. In: Proceeding blucher chemical engineering

Bassani A, Rossi F, Fiorentini C, Garrido GD, Reklaitis GVR, Bonadies I, Spigno G (2020) Model of spray-drying for encapsulation of natural extracts. In: S Pierucci, F Manenti, GL Bozzano, DBT-CACE Manca (Eds.), 30 European symposium on computer aided process engineering, Elsevier, Netherlands, Vol 48, pp 355–360 https://doi.org/10.1016/B978-0-12-823377-1.50060-4

Beigi M, Torki-Harchegani M, Mahmoodi-Eshkaftaki M (2017) Prediction of paddy drying kinetics: a comparative study between mathematical and artificial neural network modelling. Chem Ind Chem Eng Q 23(2):251–258. https://doi.org/10.2298/ciceq160524039b

Bezerra VS, Freitas-Silva O, Damasceno LF (2016) Açaí: produção de frutos, mercado e consumo (1st ed.) EMBRAPA. https://www.embrapa.br/busca-de-publicacoes/-/publicacao/1059773/acai-producao-de-frutos-mercado-e-consumo#:~:text=Resumo%3A. O açaizeiro representa um,empregado nas indústrias farmacêuticas%2C cosméticas

Borges MV, Sousa EB, Silveira MFA, Souza ARM, Alves VM, Nunes LBM, Barros SKA (2021) Physico-chemical and technological properties of acai residue flour and its use. Res Soc Dev. https://doi.org/10.33448/rsd-v10i5.14517

Cardoso AL, de Liz S, Rieger DK, Farah ACA, Kunradi Vieira FG, Altenburg de Assis MA, Di Pietro PF (2018) An update on the biological activities of euterpe edulis (juçara). Planta Med 84(8):487–499. https://doi.org/10.1055/s-0044-101624

Chandramohan VP (2020) Convective drying of food materials: an overview with fundamental aspect, recent developments, and summary. Heat Transf 49(3):1281–1313. https://doi.org/10.1002/htj.21662

CONAB (2020) Histórico Mensal de Açai. https://www.conab.gov.br/info-agro/analises-do-mercado-agropecuario-e-extrativista/analises-do-mercado/historico-mensal-de-acai

Cordeiro TR, Paula CC de A, Sousa DR de, Amorim MS (2017) Aproveitamento Do Caroço Do Açaí Como Fonte De Energia Térmica Para as Olarias do Município de Bragança Pará. VIII Congresso Brasileiro de Gestão Ambiental, 1–8

Cordeiro MDA, De Almeida O, Rocha de Castro DA, Da Silva Ribeiro HJ, Machado NT (2019) hidrólise enzimática do caroço de açaí (euterpe oleracea mart) para a produção de etanol. Rev Bras de Energ Renov. https://doi.org/10.5380/rber.v8i1.53977

Crespo-López ME, Soares ES, de Macchi BM, Santos-Sacramento L, Takeda PY, Lopes-Araújo A, de Paraense RSO, Souza-Monteiro JR, Augusto-Oliveira M, Luz DA, Maia do CSF, Rogez H, de Lima MO, Pereira JP, Oliveira DC, Burbano RR, Lima RR, Nascimento do JLM, de Arrifano GP (2019) Towards therapeutic alternatives for mercury neurotoxicity in the amazon: unraveling the pre-clinical effects of the superfruit açaí (euterpe oleracea mart) as juice for human consumption. Nutrients. https://doi.org/10.3390/nu11112585

Dan Foresee F, Hagan MT (1997). Gauss-Newton approximation to Bayesian learning.In: Proceedings of International conference on neural networks (ICNN’97), vol 3, pp 1930–1935. https://doi.org/10.1109/ICNN.1997.614194

de Moura RS, Resende ÂC (2016) Cardiovascular and metabolic effects of Açaí, an Amazon plant. J Cardiovasc Pharmacol 68(1):19–26. https://doi.org/10.1097/FJC.0000000000000347

de Almeida FNC, Johann G, Siqueira NW, Souza GK, Pereira NC (2022) Convective drying of Moringa oleifera seeds: kinetics modelling and effects on oil yield from different extraction techniques. Biomass Convers Biorefinery 12(8):3197–3208. https://doi.org/10.1007/s13399-020-01198-8

Defraeye T (2014) Advanced computational modelling for drying processes—a review. Appl Energy 131:323–344. https://doi.org/10.1016/j.apenergy.2014.06.027

Delfiya DSA, Prashob K, Murali S, Alfiya PV, Samuel MP, Pandiselvam R (2022) Drying kinetics of food materials in infrared radiation drying: a review. J Food Process Eng 45(6):e13810. https://doi.org/10.1111/jfpe.13810

Elmas F, Varhan E, Koç M (2019) Drying characteristics of jujube (Zizyphus jujuba) slices in a hot air dryer and physicochemical properties of jujube powder. J Food Meas Charact 13(1):70–86. https://doi.org/10.1007/s11694-018-9920-3

Garson GD (1991) Interpreting neural network connection weights. Artif Intell Expert 6:47–51

Garzón GA, Narváez-Cuenca C-E, Vincken J-P, Gruppen H (2017) Polyphenolic composition and antioxidant activity of açai (Euterpe oleracea Mart.) from Colombia. Food Chem 217:364–372. https://doi.org/10.1016/j.foodchem.2016.08.107

Gevrey M, Dimopoulos I, Lek S (2003) Review and comparison of methods to study the contribution of variables in artificial neural network models. Ecol Model 160(3):249–264. https://doi.org/10.1016/S0304-3800(02)00257-0

Golpour I, Kaveh M, Amiri Chayjan R, Guiné RPF (2020) Optimization of infrared-convective drying of white mulberry fruit using response surface methodology and development of a predictive model through artificial neural network. Int J Fruit Sci 20(sup2):S1015–S1035. https://doi.org/10.1080/15538362.2020.1774474

Guzzo da Silva B, Frattini Fileti AM, Pereira Taranto O (2015) Drying of brazilian pepper-tree fruits (schinus terebinthifolius raddi): development of classical models and artificial neural network approach. Chem Eng Commun 202(8):1089–1097. https://doi.org/10.1080/00986445.2014.901220

Hamid K, Sajjad U, Yang KS, Wu S-K, Wang C-C (2022) Assessment of an energy efficient closed loop heat pump dryer for high moisture contents materials: an experimental investigation and AI based modelling. Energy 238:121819. https://doi.org/10.1016/j.energy.2021.121819

Jahedi Rad S, Kaveh M, Sharabiani VR, Taghinezhad E (2018) Fuzzy logic, artificial neural network and mathematical model for prediction of white mulberry drying kinetics. Heat Mass Transf 54(11):3361–3374. https://doi.org/10.1007/s00231-018-2377-4

Karakaplan N, Goz E, Tosun E, Yuceer M (2019) Kinetic and artificial neural network modeling techniques to predict the drying kinetics of Mentha spicata L. J Food Process Preserv 43(10):e14142. https://doi.org/10.1111/jfpp.14142

Kashaninejad M, Mortazavi A, Safekordi A, Tabil LG (2007) Thin-layer drying characteristics and modeling of pistachio nuts. J Food Eng 78(1):98–108. https://doi.org/10.1016/j.jfoodeng.2005.09.007

Kaveh M, Jahanbakhshi A, Abbaspour-Gilandeh Y, Taghinezhad E, Moghimi MBF (2018) The effect of ultrasound pretreatment on quality, drying, and thermodynamic attributes of almond kernel under convective dryer using ANNs and ANFIS network. J Food Process Eng 41(7):e12868. https://doi.org/10.1111/jfpe.12868

Kaveh M, Rasooli Sharabiani V, Amiri Chayjan R, Taghinezhad E, Abbaspour-Gilandeh Y, Golpour I (2018) ANFIS and ANNs model for prediction of moisture diffusivity and specific energy consumption potato, garlic and cantaloupe drying under convective hot air dryer. Inf Process Agric 5(3):372–387. https://doi.org/10.1016/j.inpa.2018.05.003

Korese JK, Achaglinkame MA, Chikpah SK (2021) Effect of hot air temperature on drying kinetics of palmyra (Borassus aethiopum Mart.) seed-sprout fleshy scale slices and quality attributes of its flour. J Agric Food Res 6:100249. https://doi.org/10.1016/j.jafr.2021.100249

Kumar N, Sarkar BC, Sharma HK (2012) Mathematical modelling of thin layer hot air drying of carrot pomace. J Food Sci Technol 49(1):33–41. https://doi.org/10.1007/s13197-011-0266-7

Lagarias JC, Reeds JA, Wright MH, Wright PE (1998) Convergence properties of the nelder-mead simplex method in low dimensions. SIAM J Optim 9(1):112–147. https://doi.org/10.1137/S1052623496303470

Lundberg SM, Lee SI (2017) A unified approach to interpreting model predictions.In: Proceedings of the 31st international conference on neural information processing systems, 4768–4777

MacKay DJC (1992) Bayesian Interpolation. Neural Comput 4(3):415–447. https://doi.org/10.1162/neco.1992.4.3.415

Mahjoorian A, Mokhtarian M, Fayyaz N, Rahmati F, Sayyadi S, Ariaii P (2017) Modeling of drying kiwi slices and its sensory evaluation. Food Sci Nutr 5(3):466–473. https://doi.org/10.1002/fsn3.414

Marquardt DW (1963) An algorithm for least-squares estimation of nonlinear parameters. J Soc Ind Appl Math 11(2):431–441

Meerasri J, Sothornvit R (2022) Artificial neural networks (ANNs) and multiple linear regression (MLR) for prediction of moisture content for coated pineapple cubes. Case Stud Therm Eng 33:101942. https://doi.org/10.1016/j.csite.2022.101942

Meisami-Asl E, Rafiee S, Keyhani A, Tabatabaeefar A (2010) Determination of suitable thin layer drying curve model for apple slices (variety-Golab). Plant OMICS 3:103–108

Lee Kar Ming J, Saleena Taip F, Shamsul Anuar M, Bahari Mohd Noor S, Abdullah Z (2020) Artificial neural network topology optimization using k-fold cross validation for spray drying of coconut milk. IOP Conf Ser Mater Sci Eng 778(1):12094. https://doi.org/10.1088/1757-899X/778/1/012094

Mohammadi I, Tabatabaekoloor R, Motevali A (2019) Effect of air recirculation and heat pump on mass transfer and energy parameters in drying of kiwifruit slices. Energy 170:149–158. https://doi.org/10.1016/j.energy.2018.12.099

Muliterno MM, Rodrigues D, de Lima FS, Ida EI, Kurozawa LE (2017) Conversion/degradation of isoflavones and color alterations during the drying of okara. LWT 75:512–519. https://doi.org/10.1016/j.lwt.2016.09.031

Murthy TPK, Manohar B (2014) Hot air drying characteristics of mango ginger: prediction of drying kinetics by mathematical modeling and artificial neural network. J Food Sci Technol 51(12):3712–3721. https://doi.org/10.1007/s13197-013-0941-y

Nagata GA, Costa TV, Perazzini MTB, Perazzini H (2020a) Coupled heat and mass transfer modelling in convective drying of biomass at particle-level: Model validation with experimental data. Renew Energy 149:1290–1299. https://doi.org/10.1016/j.renene.2019.10.123

Nagata GA, Souto BA, Perazzini MTB, Perazzini H (2020b) Analysis of the isothermal condition in drying of acai berry residues for biomass application. Biomass Bioenerg 133:105453. https://doi.org/10.1016/j.biombioe.2019.105453

Nazghelichi T, Kianmehr MH, Aghbashlo M (2011) Prediction of carrot cubes drying kinetics during fluidized bed drying by artificial neural network. J Food Sci Technol 48(5):542–550. https://doi.org/10.1007/s13197-010-0166-2

Oladejo AO, Ekpene M-AM, Onwude DI, Assian UE, Nkem OM (2021) Effects of ultrasound pretreatments on the drying kinetics of yellow cassava during convective hot air drying. J Food Process Preserv 45(3):e15251. https://doi.org/10.1111/jfpp.15251

Oliveira AG, Costa MCD, Rocha SMBDM (2015) Benefícios funcionais do açaí na prevenção de doenças cardiovasculares. J Amzon Health Sci 1:1–10

Oliveira M, do S, Carvalho J, Nascimento W (2000) Açaí (Euterpe oleracea Mart.)

Omid M, Baharlooei A, Ahmadi H (2009) Modeling drying kinetics of pistachio nuts with multilayer feed-forward neural network. Drying Technol 27(10):1069–1077. https://doi.org/10.1080/07373930903218602

Ottaiano GY, da Cruz INS, da Cruz HS, Martins TD (2021) Estimation of vaporization properties of pure substances using artificial neural networks. Chem Eng Sci, 231, 116324. https://doi.org/10.1016/j.ces.2020.116324

Panchariya PC, Popovic D, Sharma AL (2002) Thin-layer modelling of black tea drying process. J Food Eng 52(4):349–357. https://doi.org/10.1016/S0260-8774(01)00126-1

Pavan MA (2010) Effects of freeze drying, refractance window drying and hot-air drying on the quality parameters of açaí. In: Effects of freeze drying, refractance window drying and hot-air drying on the quality parameters of Açaí. University of Illinois at Urbana-Champaign, Vol 8, Issue 1

Perazzini H, Freire FB, Freire JT (2013) Drying kinetics prediction of solid waste using semi-empirical and artificial neural network models. Chem Eng Technol 36(7):1193–1201. https://doi.org/10.1002/ceat.201200593

Powell MJD (1977) Restart procedures for the conjugate gradient method. Math Program 12(1):241–254. https://doi.org/10.1007/BF01593790

Prakash O, Kumar A (2014) Application of artificial neural network for the prediction of jaggery mass during drying inside the natural convection greenhouse dryer. Int J Ambient Energy 35(4):186–192. https://doi.org/10.1080/01430750.2013.793455

Rasooli Sharabiani V, Kaveh M, Abdi R, Szymanek M, Tanaś W (2021) Estimation of moisture ratio for apple drying by convective and microwave methods using artificial neural network modeling. Sci Rep 11(1):9155. https://doi.org/10.1038/s41598-021-88270-z

Reis BDO, da Silva IT, da Silva IMO, da Rocha BRP (2002) Produção de briquetes energéticos a partir de caroços de açaí. Scielo 091:1–6

Riedmiller M, Braun H (1993) A direct adaptive method for faster backpropagation learning: the RPROP algorithm.In: IEEE international conference on neural networks, vol 1, pp 586–591 https://doi.org/10.1109/ICNN.1993.298623

Rodríguez J, Clemente G, Sanjuán N, Bon J (2013) Modelling drying kinetics of thyme (Thymus vulgaris L.): theoretical and empirical models, and neural networks. Food Sci Technol Int 20(1):13–22. https://doi.org/10.1177/1082013212469614

Rogez UCL (2000) Aça{\’\i}: preparo, composição e melhoramento da conservação. EDUFPA. https://books.google.com.br/books?id=-THExAEACAAJ

Schulz M, da Silva Campelo Borges G, Gonzaga LV, Oliveira Costa AC, Fett R (2016) Juçara fruit (Euterpe edulis Mart.): sustainable exploitation of a source of bioactive compounds. Food Res Int (Ottawa, Ont.) 89(Pt 1):14–26. https://doi.org/10.1016/j.foodres.2016.07.027

da Silva LTA, Pantoja CLG, de Oliveira DECM, Hofstatter GA, dos Santos APS (2018) Caroço de açaí como fonte alternativa de energia e redução de impactos ambientais no Pará. Meio Ambiente Sustent e Tecnola 4:1–6. https://doi.org/10.36229/978-65-5866-001-9.cap.12

da Silva AO, de Mera WYWL, de Souza DP, Santos DCR, da Júnior AMGS (2020) AÇAÍ (euterpe oleracea mart) production study: economic and productive aspects based on 2015–2017. Braz J Dev 6(1):1629–1641. https://doi.org/10.3117/bjdv6n1-112

da Simão RS, Zhang L, de Moraes JO, Schröder A, Laurindo JB, Schutyser MAI (2022) Low-pressure conductive thin film drying of açaí pulp. LWT 164:113695. https://doi.org/10.1016/j.lwt.2022.113695

Simha P, Mathew M, Ganesapillai M (2016) Empirical modeling of drying kinetics and microwave assisted extraction of bioactive compounds from Adathoda vasica and Cymbopogon citratus. Alex Eng J 55(1):141–150. https://doi.org/10.1016/j.aej.2015.12.020

Sun Q, Zhang M, Mujumdar AS (2019) Recent developments of artificial intelligence in drying of fresh food: a review. Crit Rev Food Sci Nutr 59(14):2258–2275. https://doi.org/10.1080/10408398.2018.1446900

Tan S, Miao Y, Zhou C, Luo Y, Lin Z, **e R, Li W (2022) Effects of hot air drying on drying kinetics and anthocyanin degradation of blood-flesh peach. Foods. https://doi.org/10.3390/foods11111596

Townsend CR, Costa NDL, de Pereira RGA, Senger CCD (2001) Características químico-bromatológicas do caroço de açaí. Comun Téc Embr 193(1):3–8

da Valente MCC, do Nascimento RA, Santana EB, da Ribeiro NFP, Costa CML, de Faria LJG (2019) Spray drying of extract from euterpe oleracea mart.: optimization of process and characterization of the açaí powder. J Food Process Eng 42(8):e13253. https://doi.org/10.1111/jfpe.13253

Wang D, He H, Liu D (2018) Intelligent optimal control with critic learning for a nonlinear overhead crane system. IEEE Trans Industr Inf 14(7):2932–2940. https://doi.org/10.1109/TII.2017.2771256

Yaciuk G (1981) 24—Solar crop drying (AF Janzen, RKBT-SECII Swartman (eds.). Pergamon. pp 377–396 https://doi.org/10.1016/B978-0-08-025388-6.50049-0

de Yamaguchi KKL, Pereira LFR, Lamarão CV, Lima ES, da Veiga-Junior VF (2015) Amazon acai: chemistry and biological activities: a review. Food Chem 179:137–151. https://doi.org/10.1016/j.foodchem.2015.01.055

Zhu Y, Wang P, Sun D, Qu Z, Yu B (2021) Multiphase porous media model with thermo-hydro and mechanical bidirectional coupling for food convective drying. Int J Heat Mass Transf 175:121356. https://doi.org/10.1016/j.ijheatmasstransfer.2021.121356

Zogzas NP, Maroulis ZB, Marinos-Kouris D (1996) Moisture diffusivity data compilation in foodstuffs. Drying Technol 14(10):2225–2253. https://doi.org/10.1080/07373939608917205

Funding

No funds, grants, or other support were received.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bannoud, M.A., Gomes, B.P., Abdalla, M.C.S.P. et al. Mathematical modeling of drying kinetics of ground Açaí (Euterpe oleracea) kernel using artificial neural networks. Chem. Pap. 78, 1033–1054 (2024). https://doi.org/10.1007/s11696-023-03142-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-023-03142-2