Abstract

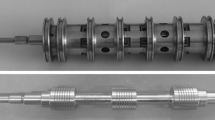

AISI 440C is a high carbon martensitic stainless steel with superior wear and abrasion resistance among all grades of stainless steel. Hydraulic amplifier valve (HAV) spools, made of AISI 440C stainless steel, are used in flow control devices of launch vehicle actuator systems. In the present case, a failure occurred near the undercut region of the HAV spool during the vibration test. The failure was observed specifically at M5 threaded region of the spool. A detailed investigation has been carried out to understand the root cause of the failure. 612 µm deep pit was observed with corrosion products on the fracture surface near to the undercut region of M5 thread. Elemental chemical composition analysis via energy-dispersive X-ray spectroscopy (EDS) confirmed the presence of oxygen and chlorine in the pit location. Primary carbides exposed to the rough machined surface at the undercut region lead to the pit initiation and propagation because of the galvanic potential difference between matrix and primary carbides. Failure of the HAV spool is attributed to corrosion-assisted overload.

Similar content being viewed by others

References

S.C. Krishna, K.T. Tharian, K.V.A. Chakravarthi, A.K. Jha, B. Pant, Heat treatment and thermo-mechanical treatment to modify carbide banding in AISI 440C steel: a case study. Metallogr. Microstruct. Anal. 5, 108–115 (2016). https://doi.org/10.1007/s13632-016-0266-0

S.K. Manwatkar, A. Bahrudheen, S.B. Tiwari, S.V.S. Narayana Murty, P. Ramesh Narayanan, Failure analysis of AISI 440C steel ball screws used in the actuator system of a satellite launch vehicle. J. Fail. Anal. Prevent. 17(3), 505–512 (2017). https://doi.org/10.1007/s11668-017-0268-5

K. Jalaja, S.K. Manwatkar, P. Anand, R. Rejith, S.V.S. NarayanaMurty, Metallurgical analysis of surface distress on balls during the operation of AISI 440C ball bearings for satellite applications. Eng. Fail. Anal. 124, 105376 (2021). https://doi.org/10.1016/j.engfailanal.2021.105376

S. Pahlavan, S. Moazen, I. Taji, K. Saffar, M. Hamrah, M. Moayed, S.M. Beidokhti, Pitting corrosion of martensitic stainless steel in halide bearing solutions. Corros. Sci. 112, 233–240 (2016)

A. Barroux, N. Ducommun, E. Nivet, L. Laffont, C. Blanc, Pitting corrosion of 17–4PH stainless steel manufactured by laser beam melting. Corros. Sci. 169, 108594 (2020)

J.S. Sheasby, T.L. Walzak, The effect of heat treatment parameters on the anodic polarization behavior of 440C stainless steel. Corrosion. 39(12), 502–507 (1983)

J.S. Sheasby, T.L. Walzak, Passivation of 440C stainless steel and the copper sulphate test. In International Congress on Metallic Corrosion, Toronto, Canada, 3–7 Jun 1994, pp. 444–448

Anon, Steel, corrosion resistant, bars, wire and forgings, 17Cr-0.52 Mo-(0.95 to 1.2 C) (SAE 51440C), consumable electrode vacuum melted. In Aerospace Material Specification—AMS 5618F, (SAE International, Warrendale, PA, 2000).

T.P. Savas, A.Y.-L. Wang, J.C. Earthman, The effect of heat treatment on the corrosion resistance of 440C stainless steel in 20% HNO3 + 2.5% Na2Cr2O7 solution. J. Mater. Eng. Perform. 12(2), 165–171 (2003). https://doi.org/10.1361/105994903770343303

J.R. Yang, T.H. Yu, C.H. Wang, Martensitic transformations in AISI 440C stainless steel. Mater. Sci. Eng. A. 438–440, 276–280 (2006). https://doi.org/10.1016/j.msea.2006.02.098

H.K.D.H. Bhadeshia, Steels for bearings. Prog. Mater. Sci. 57, 268–435 (2012). https://doi.org/10.1016/j.pmatsci.2011.06.002

J.R.J. Marcuci, E.C. De Souza, C.C. Camilo, P.L. Di Lorenzo, J.M.D.A. de Rollo, Corrosion and microstructural characterization of martensitic stainless steels submitted to industrial thermal processes for use in surgical tools. Rev. Bras. Eng. Biomed. 30, 257–264 (2014). https://doi.org/10.1590/rbeb.2014.025

K. Jalaja, S.K. Manwatkar, R.K. Gupta, S.N. Murty, Metallurgical analysis of failed AISI 440C hydraulic amplifier valve spool for launch vehicle actuators. J. Fail. Anal. Prevent. 23(2), 728–738 (2023). https://doi.org/10.1007/s11668-023-01597-9

Acknowledgments

Authors wish to place on record their deep sense of gratitude to Group Director, Materials and Metallurgy Group and Deputy Director, Materials and Mechanical Entity for their encouragement and support during the course this work. Authors acknowledge Director, VSSC for permission to publish the work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yerrinaidu, L., Jalaja, K., Manwatkar, S.K. et al. Root Cause Analysis of Failed AISI 440C High Carbon Stainless Steel Used in Aerospace Actuator Systems. J Fail. Anal. and Preven. 24, 1490–1499 (2024). https://doi.org/10.1007/s11668-024-01940-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-024-01940-8