Abstract

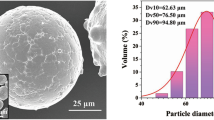

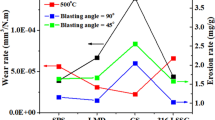

304 stainless steel (304SS) powder and novel Mo-cladded 304SS (304SS-Mo) powder were used as feedstocks to prepare metallic coatings with different inter-splat bonding qualities. Wear test was conducted to examine the dependence of wear behavior on the inter-splat bonding quality. The results showed that poor inter-splat bonding leads to much lower wear resistance in conventional 304SS coating relative to that of 304SS bulk, especially at high loading conditions (>75 N), where the wear rate increased to 5.53 × 10−3 mm3/(m⋅N) by 3.5 times higher than that at low-load range. However, the novel 304SS-Mo coating with metallurgical inter-splat bonding and minimized oxide inclusions exhibited a low wear rate comparable to that of 304SS bulk. Failure analysis of worn samples suggests that splat delamination contributes to low wear resistance of the 304SS coating; conversely, the absence of splat delamination results in higher wear resistance of the 304SS-Mo coating. Using Mo-cladded powders, significantly enhanced inter-splat bonding enables the use of plasma-sprayed metallic coating under high-load wear conditions. The strong dependence of wear resistance on the load in conventional coating implies that evaluation of wear performance of thermally sprayed metallic coating should consider both the wear rate and critical load.

Similar content being viewed by others

References

R. Mcpherson and B.V. Shafer, Interlamellar Contact within Plasma Sprayed Coatings, Thin Solid Films., 1982, 97, p 201–204.

C.J. Li and A. Ohmori, Relationships Between the Microstructure and Properties of Thermally Sprayed Deposits, J. Therm. Spray Technol., 2002, 11, p 365–374.

C.J. Li, G.J. Yang, and A. Ohmori, Relationship Between Particle Erosion and Lamellar Microstructure for Plasma-sprayed Alumina Coatings, Wear, 2006, 260, p 1166–1172.

R. Mcpherson, A Review of Microstructure and Properties of Plasma Sprayed Ceramic Coatings, Surf. Coat. Technol., 1989, 39–40(89), p 173–181.

M. Vardelle, A. Vardelle, and A.C. Leger, Influence of Particle Parameters at Impact on Splat Formation and Solidification in Plasma Spraying Processes, J. Therm. Spray Technol., 1995, 4(1), p 50–58.

S. Deshpande, S. Sampath, and H. Zhang, Mechanisms of Oxidation and Its Role in Microstructural Evolution of Metallic Thermal Spray Coatings-Case Study for Ni-Al, Surf. Coat. Technol., 2006, 200, p 5395–5406.

Z. Zeng, S. Kuroda, and H. Era, Comparison of Oxidation Behavior of Ni-20Cr Alloy and Ni-base Self-fluxing Alloy During Air Plasma Spraying, Surf. Coat. Technol., 2009, 204, p 69–77.

Z. Zeng, S. Kuroda, J. Kawakita, M. Komatsu, and H. Era, Effects of Some Light Alloying Elements on the Oxidation Behavior of Fe and Ni-Cr Based Alloys During Air Plasma Spraying, J. Therm. Spray Technol.l., 2010, 19, p 128–136.

J. Wang, X.T. Luo, C.J. Li, N.S. Ma, and M. Takahashi, Effect of Substrate Temperature on the Microstructure and Interface Bonding Formation of Plasma Sprayed Ni20Cr Splat, Surf. Coat. Technol., 2019, 371, p 36–46.

J. Wang, C.J. Li, G.J. Yang, and C.X. Li, Effect of Oxidation on the Bonding Formation of Plasma-Sprayed Stainless Steel Splats onto Stainless Steel Substrate, J. Therm. Spray Technol., 2017, 26(1–2), p 1–13.

J. Wang and C.J. Li, The Effect of Molybdenum Substrate Oxidation on Molybdenum Splat Formation, J. Therm. Spray Technol., 2018, 27, p 14–24.

O. Poliarus, J. Morgiel, P. Bobrowski, M. Szlezynger, O. Umanskyi, M. Ukrainets, L. Maj, and O. Kostenko, Effect of Powder Preparation on the Microstructure and Wear of Plasma-Sprayed NiAl/CrB2 Composite Coatings, J. Therm. Spray Technol., 2019, 28, p 1039–1048.

J.J. Tian, X.T. Luo, J. Wang, and C.J. Li, Mechanical Performance of Plasma-sprayed Bulk-like NiCrMo Coating with a Novel Shell-core-structured NiCr-Mo Particle, Surf. Coat. Technol., 2018, 353, p 179–186.

S. Houdková, E. Smazalová, M. Vostřák, and J. Schubert, Properties of NiCrBSi Coating, as Sprayed and Remelted by Different Technologies, Surf. Coat. Technol., 2014, 253, p 14–26.

R. Ahmed, O. Ali, C.C. Berndt, and A. Fardan, Sliding Wear of Conventional and Suspension Sprayed Nanocomposite WC-Co Coatings: An Invited Review, J. Therm. Spray Technol., 2021, 30, p 800–861.

C.J. Li, X.T. Luo, S.W. Yao, G.R. Li, C.X. Li, and G.J. Yang, The Bonding Formation During Thermal Spraying of Ceramic Coatings: A Review, J. Therm. Spray Technol., 2022, 31, p 780–817.

K.H. ZumGahr, Wear by Hard Particles, Tribol. Int., 1998, 31, p 587–596.

Y. Arata, A. Ohmori, and C.J. Li, Fracture Behavior of Plasma Sprayed Ceramic Coatings in Scratch Test, Transactions of Japan Weld. Res. Inst., 1988, 17, p 31–35.

P.A. Engel and F.F. Ling, Impact Wear of Materials, J. Appl. Mech., 1976, 45, p 458–459.

J.G.A. Bitter, A Study of Erosion Phenomena, Wear, 1963, 6(1), p 5–21.

W. Tillmann, W. Luo, and U. Selvadurai, Wear Analysis of Thermal Spray Coatings on 3D Surfaces, J. Therm. Spray Technol., 2014, 23(1–2), p 245–251.

V. Varadaraajan, R. Guduru, and P.S. Mohanty, Property Evolution in Amorphous Steel Coatings by Different Thermal Spray Processes, J. Therm. Spray Technol., 2022, 31, p 1056–1066.

M.A. Faridi, S.K. Nayak, D.K.V.D. Prasad, A. Kumar, and T. Laha, Effect of Microstructure and Phase Evolution on the Wear Behavior of Fe-Based Amorphous/Nanocrystalline Composite Coatings Synthesized by Plasma Spraying, J. Therm. Spray Technol. Therm. Spray Technol., 2023, 32, p 2054–2067.

P. Sassatelli, G. Bolelli, M.L. Gualtieri, E. Heinonen, M. Honkanen, L. Lusvarghi, T. Manfredini, R. Rigon, and M. Vippola, Properties of HVOF-sprayed Stellite-6 Coatings, Surf. Coat. Technol., 2018, 338, p 45–62.

P.P. Zhang, S.Y. Jiang, Y.J. Guo, Y.F. Sui, X.Y. Ding, Z.H. Yao, Q.L. Zhang, and J.H. Yao, Microstructures and Wear Resistance of Mo Coating Fabricated by In Situ Laser-Assisted Plasma Spraying, J. Therm. Spray Technol., 2023 https://doi.org/10.1007/s11666-023-01683-2

Y.C. Zhu, K. Yukimura, C.X. Ding, and P.Y. Zhang, Tribological Properties of Nanostructured and Conventional WC-Co Coatings Deposited by Plasma Spraying, Thin Solid Films, 2001, 388, p 277–282.

T. Sudaprasert, P.H. Shipway, and D.G. Mccartney, Sliding Wear Behaviour of HVOF Sprayed WC-Co Coatings Deposited with Both Gas-fuelled and Liquid-fuelled Systems, Wear, 2003, 255, p 943–949.

P.H. Shipway, D.G. McCartney, and T. Sudaprasert, Sliding Wear Behaviour of Conventional and Nanostructured HVOF Sprayed WC-Co Coatings, Wear, 2005, 259, p 820–827.

J. Ahn, B. Hwang, and S. Lee, Improvement of Wear Resistance of Plasma-Sprayed Molybdenum Blend Coatings, J. Therm. Spray Technol., 2005, 14(2), p 251–257.

J.H. Yan, Z.Y. He, Y. Wang, J.W. Qiu, and Y.M. Wang, Microstructure and Wear Resistance of Plasma-Sprayed Molybdenum Coating Reinforced by MoSi2 Particles, J. Therm. Spray Technol., 2016, 25(7), p 1322–1329.

W.F. Xu, Y.R. Niu, H. Ji, H. Li, C.K. Chang, and X.B. Zheng, Effect of Ni Addition on Microstructure and Tribological Properties of Plasma-Sprayed MoSi2 Coatings, J. Therm. Spray Technol., 2018, 27, p 1632–1642.

X.Y. Dong, X.T. Luo, S.L. Zhang, and C.J. Li, A Novel Strategy for Depositing Dense Self-fluxing Alloy Coatings with Sufficiently Bonded Splats by One-Step Atmospheric Plasma Spraying, J. Therm. Spray Technol., 2020, 29, p 173–184.

X.J. Liao, L. Zhang, X.Y. Dong, X. Chen, X.T. Luo, and C.J. Li, Self-bonding Effect Development for Plasma Spraying of Stainless Steel Coating Through Using Mo-clad Stainless Steel Powders, JOM, 2020, 72(12), p 4613–4623.

X.J. Liao, X.T. Luo, L. Zhang, X. Chen, Y.Q. Sun, C.X. Li, G.J. Yang, and C.J. Li, Mo-alloyed Stainless Steel Coating with Improved Cavitation Erosion Resistance by Plasma Spraying a Specially Designed Core-shell-structured Powder, Wear, 2023, 528–529, 204961.

Y.P. Wan, J.R. Fincke, and S. Sampath, Modeling and Experimental Observation of Evaporation from Oxidizing Molybdenum Particles Entrained in a Thermal Plasma Jet, Int. J. Heat Mass Transf.Heat Mass Transf., 2002, 45, p 1007–1015.

R.T. Allsop, T.J. Pitt, and J.V. Hardy, The Adhesion of Sprayed Molybdenum, Metallurgia, 1961, 63, p 125–131.

S. Kitahara and A. Hasui, Study of the Bonding Mechanism of Sprayed Coatings, J. Vac. Sci. Technol., 1974, 11, p 747–753.

S. Sampath, G.A. Bancke, and H. Herman, Plasma Sprayed Ni-Al Coatings, Surf. Eng., 1989, 5, p 293–298.

V.V. Sobolev, J.M. Guilemany, J. Nutting, and J.R. Miquel, Development of Substrate-Coating Adhesion in Thermal Spraying, Int. Mater. Rev., 1997, 42(3), p 117–136.

L. Li, X.Y. Wang, G. Wei, A. Vaidya, H. Zhang, and S. Sampath, Substrate Melting During Thermal Spray Splat Quenching, Thin Solid Films, 2004, 468, p 113–119.

C.J. Li, X.T. Luo, X.Y. Dong, L. Zhang, and C.X. Li, Recent Research Advances in Plasma Spraying of Bulk-Like Dense Metal Coatings with Metallurgically Bonded Lamellae, J. Therm. Spray Technol., 2022, 31, p 5–27.

S. Matthews, Shrouded Plasma Spray of Ni-20Cr Coatings Utilizing Internal Shroud Film Cooling, Surf. Coat. Technol., 2014, 249, p 56–74.

“Standard Test Method for Adhesion or Cohesion Strength of Thermal Spray Coatings,” C633, Annual Book of ASTM Standards, Part 3, ASTM, 1-7 (2001)

J. Wang, J.D. **ng, L. Cao, W. Su, and Y.M. Gao, Dry Sliding Wear Behavior of Fe3Al Alloys Prepared by Mechanical Alloying and Plasma Activated Sintering, Wear, 2010, 268, p 473–480.

J.J. Tian, S.W. Yao, X.T. Luo, C.X. Li, and C.J. Li, An Effective Approach for Creating Metallurgical Self-bonding in Plasma-spraying of NiCr-Mo Coating by Designing Shell-core-structured Powders, Acta Mater., 2016, 110, p 19–30.

J.J. Tian, Y.K. Wei, C.X. Li, G.J. Yang, and C.J. Li, Effect of Post-spray Shot Peening Treatment on the Corrosion Behavior of NiCr-Mo Coating by Plasma Spraying of the Shell-Core-Structured Powders, J. Therm. Spray Technol., 2018, 27, p 232–242.

J.J. Tian, S.W. Yao, S.L. Zhang, and C.J. Li, Effect of the Shell-core-structured Particle Design on the Heating Characteristic of Nickel-based Alloy Particle During Plasma Spraying, Surf. Coat. Technol., 2018, 335, p 52–61.

X. Zhou, Y.M. Gao, and Y.R. Wang, Wear Behavior of Ni-coated Carbon Fiber and ZrC Particles Reinforced 2024Al Matrix Composites, Wear, 2023, 528–529, 204967.

E.O. Olakanmi and M. Doyoyo, Laser-Assisted Cold-Sprayed Corrosion and Wear-Resistant Coatings: A Review, J. Therm. Spray Technol., 2014, 23(5), p 765–785.

K. Szymański, A. Hernas, G. Moskal, and H. Myalska, Thermally Sprayed Coatings Resistant to Erosion and Corrosion for Power Plant Boilers-A Review, Surf. Coat. Technol., 2015, 268, p 153–164.

M. Tkadletz, N. Schalk, R. Daniel, J. Keckes, C. Czettl, and C. Mitterer, Advanced Characterization Methods for Wear Resistant Hard Coatings: A review on Recent Progress, Surf. Coat. Technol., 2016, 285, p 31–46.

B. Huang, C. Zhang, G. Zhang, and H.L. Liao, Wear and Corrosion Resistant Performance of Thermal-sprayed Fe-based Amorphous Coatings: A Review, Surf. Coat. Technol., 2019, 377, 124896.

J.A. Gan and C.C. Berndt, Review on the Oxidation of Metallic Thermal Sprayed Coatings: A Case Study with Reference to Rare-Earth Permanent Magnetic Coatings, J. Therm. Spray Technol., 2013, 22(7), p 1069–1091.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (52031010, U1837201); Key Research and Development Program of Jiangxi Academy of Sciences (2021YSBG21005, 2023YJC2013, 2023YSBG21011).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

About this article

Cite this article

Liao, XJ., Zhang, L., Sun, YQ. et al. Effect of Inter-Splat Bonding Quality on the Dependence of Wear Behavior of Plasma-Sprayed Stainless Steel Coating on Applied Load. J Therm Spray Tech 33, 1559–1569 (2024). https://doi.org/10.1007/s11666-024-01774-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-024-01774-8