Abstract

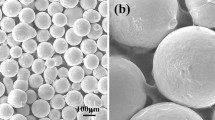

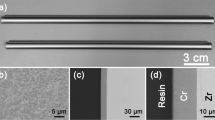

A dense and continuous Cr coating with a thickness of approximately 140 μm was successfully deposited on the surface of a thin-walled Zr alloy cladding tube using high-speed laser cladding technology in this study. The microstructure, phase composition, microhardness, and resistance to high-temperature oxidation of the coating were investigated. The experimental results showed that the Cr coating exhibited high-strength metallurgical bond with the Zr alloy substrate, forming a narrow heat-affected zone with a thickness of 25 μm, and the coating consists of ZrCr2 and α-Zr phase. The average microhardness of the coating was 589 HV0.05, about 2.3 times that of the substrate. After oxidation at 1200 °C for 1200 s in air, with the formation of complete and dense protective Cr2O3 scale, the Cr-coated Zr alloy cladding tube showed better high-temperature oxidation resistance than uncoated tube.

Similar content being viewed by others

References

J.H. Park, H.G. Kim, J.Y. Park, Y.I. Jung, D.J. Park, and Y.H. Koo, High Temperature Steam-Oxidation Behavior of Arc Ion Plated Cr Coatings for Accident Tolerant Fuel Claddings, Surf. Coat. Technol., 2015, 280, p 256-259. https://doi.org/10.1016/j.surfcoat.2015.09.022

A.S. Kuprin, V.A. Belous, V.N. Voyevodin, V.V. Bryk, R.L. Vasilenko, V.D. Ovcharenko, E.N. Reshetnyak, G.N. Tolmachova, and P.N. V’Yugov, Vacuum-Arc Chromium-Based Coatings for Protection of Zirconium Alloys from the High-Temperature Oxidation in Air, J. Nucl. Mater., 2015, 465, p 400-406. https://doi.org/10.1016/j.jnucmat.2015.06.016

I. Younker and M. Fratoni, Neutronic Evaluation of Coating and Cladding Materials for Accident Tolerant Fuels, Prog. Nucl. Energy, 2016, 88, p 10-18. https://doi.org/10.1016/j.pnucene.2015.11.006

E. Alat, A.T. Motta, R.J. Comstock, J.M. Partezana, and D.E. Wolfe, Ceramic Coating for Corrosion (c3) Resistance of Nuclear Fuel Cladding, Surf. Coat. Technol., 2015, 281, p 133-143. https://doi.org/10.1016/j.surfcoat.2015.08.062

S.J. Zinkle, K.A. Terrani, J.C. Gehin, L.J. Ott, and L.L. Snead, Accident Tolerant Fuels for LWRs: A Perspective, J. Nucl. Mater., 2014, 448(1), p 374-379. https://doi.org/10.1016/j.jnucmat.2013.12.005

L.J. Ott, K.R. Robb, and D. Wang, Preliminary Assessment of Accident-Tolerant Fuels on LWR Performance During Normal Operation and Under DB and BDB Accident Conditions, J. Nucl. Mater., 2014, 448(1), p 520-533. https://doi.org/10.1016/j.jnucmat.2013.09.052

R.B. Rebak, Alloy Selection for Accident Tolerant Fuel Cladding in Commercial Light Water Reactors, Metall. Mater. Trans. E, 2015, 2(4), p 197-207. https://doi.org/10.1007/s40553-015-00576

L. Duc Huy, P. Laffez, P. Daniel, A. Jouanneaux, N. The Khoi, and D. Siméone, Structure and Phase Component of ZrO2 Thin Films Studied by Raman Spectroscopy and X-ray Diffraction, Mater. Sci. Eng. B., 2003, 104(3), p 163-168. https://doi.org/10.1016/S0921-5107(03)00190-9

Y. Al-Olayyan, G.E. Fuchs, R. Baney, and J. Tulenko, The Effect of Zircaloy-4 Substrate Surface Condition on the Adhesion Strength and Corrosion of SiC Coatings, J. Nucl. Mater., 2005, 346(2), p 109-119. https://doi.org/10.1016/j.jnucmat.2005.05.016

K. Daub, R. Van Nieuwenhove, and H. Nordin, Investigation of the Impact of Coatings on Corrosion and Hydrogen Uptake of Zircaloy-4, J. Nucl. Mater., 2015, 467, p 260-270. https://doi.org/10.1016/j.jnucmat.2015.09.041

T. Cheng, J.R. Keiser, M.P. Brady, K.A. Terrani, and B.A. Pint, Oxidation of Fuel Cladding Candidate Materials in Steam Environments at High Temperature and Pressure, J. Nucl. Mater., 2012, 427(1), p 396-400. https://doi.org/10.1016/j.jnucmat.2012.05.007

Z. Feng, P. Ke, and A. Wang, Preparation of Ti2AlC MAX Phase Coating by DC Magnetron Sputtering Deposition and Vacuum Heat Treatment, J. Mater. Sci. Technol., 2015, 31(12), p 1193-1197. https://doi.org/10.1016/j.jmst.2015.10.014

D.J. Tallman, L. He, B.L. Garcia-Diaz, E.N. Hoffman, G. Kohse, R.L. Sindelar, and M.W. Barsoum, Effect of Neutron Irradiation on Defect Evolution in Ti3SiC2 and Ti2AlC, J. Nucl. Mater., 2016, 468, p 194-206. https://doi.org/10.1016/j.jnucmat.2015.10.030

H.G. Kim, I.H. Kim, Y.I. Jung, D.J. Park, J.Y. Park, and Y.H. Koo, Adhesion Property and High-Temperature Oxidation Behavior of Cr-coated Zircaloy-4 Cladding Tube Prepared by 3D Laser Coating, J. Nucl. Mater., 2015, 465, p 531-539. https://doi.org/10.1016/j.jnucmat.2015.06.030

H.G. Kim, J.H. Yang, W.J. Kim, and Y.H. Koo, Development Status of Accident-Tolerant Fuel for Light Water Reactors in Korea, Nucl. Eng. Technol., 2016, 48(1), p 1-15. https://doi.org/10.1016/j.net.2015.11.011

Y. Wang, W. Zhou, Q. Wen, X. Ruan, F. Luo, G. Bai, Y. Qing, D. Zhu, Z. Huang, Y. Zhang, T. Liu, and R. Li, Behavior of Plasma Sprayed Cr Coatings and FeCrAl Coatings on Zr Fuel Cladding Under Loss-of-Coolant Accident Conditions, Surf. Coat. Technol., 2018, 344, p 141-148. https://doi.org/10.1016/j.surfcoat.2018.03.016

T. Usui, A. Sawada, M. Amaya, A. Suzuki, T. Chikada, and T. Terai, SiC Coating as Hydrogen Permeation Reduction and Oxidation Resistance for Nuclear Fuel Cladding, J. Nucl. Sci. Technol., 2015, 52(10), p 1318-1322. https://doi.org/10.1080/00223131.2015.1020901

E. Alat, A.T. Motta, R.J. Comstock, J.M. Partezana, and D.E. Wolfe, Multilayer (TiN, TiAlN) Ceramic Coatings for Nuclear Fuel Cladding, J. Nucl. Mater., 2016, 478, p 236-244. https://doi.org/10.1016/j.jnucmat.2016.05.021

Z.B. Qi, B. Liu, Z.T. Wu, F.P. Zhu, Z.C. Wang, and C.H. Wu, A Comparative Study of the Oxidation Behavior of Cr2N and CrN Coatings, Thin Solid Films, 2013, 544, p 515-520. https://doi.org/10.1016/j.tsf.2013.01.031

Y.C. Chim, X.Z. Ding, X.T. Zeng, and S. Zhang, Oxidation Resistance of TiN, CrN, TiAlN and CrAlN Coatings Deposited by Lateral Rotating Cathode Arc, Thin Solid Films, 2009, 517(17), p 4845-4849. https://doi.org/10.1016/j.tsf.2009.03.038

A. Michau, F. Maury, F. Schuster, F. Lomello, J.C. Brachet, E. Rouesne, M. Le Saux, R. Boichot, and M. Pons, High-Temperature Oxidation Resistance of Chromium-Based Coatings Deposited by DLI-MOCVD for Enhanced Protection of the Inner Surface of Long Tubes, Surf. Coat. Technol., 2018, 349, p 1048-1057. https://doi.org/10.1016/j.surfcoat.2018.05.088

A. Fazi, M. Sattari, K. Stiller, H.O. Andrén, and M. Thuvander, Performance and Evolution of Cold Spray Cr-Coated Optimized ZIRLO™ Claddings Under Simulated Loss-of-Coolant Accident Conditions, J. Nucl. Mater., 2023, 576, p 154268.

D. Wang, R. Zhong, Y. Zhang, P. Chen, Y. Lan, J. Yu, G.H. Su, S. Qiu, and W. Tian, Isothermal Experiments on Steam Oxidation of Magnetron-Sputtered Chromium-Coated Zirconium Alloy Cladding at 1200 °C, Corros. Sci., 2022, 206, p 110544.

M. Huang, Y. Li, G. Ran, Z. Yang, and P. Wang, Cr-Coated Zr-4 Alloy Prepared by Electroplating and Its in Situ He+ Irradiation Behavior, J. Nucl. Mater., 2020, 538, p 152240.

J.C. Pereira, J.C. Zambrano, M.J. Tobar, A. Yañez, and V. Amigó, High Temperature Oxidation Behavior of Laser Cladding MCrAlY Coatings on Austenitic Stainless Steel, Surf. Coat. Technol., 2015, 270, p 243-248. https://doi.org/10.1016/j.surfcoat.2015.02.050

T. Schopphoven, A. Gasser, and G. Backes, EHLA: Extreme High-Speed Laser Material Deposition, Laser Technol. J., 2017, 14(4), p 26-29. https://doi.org/10.1002/latj.201700020

T. Schopphoven, A. Gasser, K. Wissenbach, and R. Poprawe, Investigations on Ultra-High-Speed Laser Material Deposition as Alternative for Hard Chrome Plating and Thermal Spraying, J. Laser Appl., 2016, 28(2), p 022501. https://doi.org/10.2351/1.4943910

L.Y. Lou, K.C. Liu, Y.J. Jia, G. Ji, W. Wang, C.J. Li, and C.X. Li, Microstructure and Properties of Lightweight Al0.2CrNbTiV Refractory High Entropy Alloy Coating with Different Dilutions Deposited by High Speed Laser Cladding, Surf. Coat. Technol., 2022, 447, p 128873.

L.Q. Li, F.M. Shen, Y.D. Zhou, W. Tao, W. Wang, and S.L. Wang, Comparison of Microstructure and Corrosion Resistance of 431 Stainless Steel Coatings Prepared by Extreme High-Speed Laser Cladding and Conventional Laser Cladding, Chin. J. Lasers, 2019, 46, p 1002010.

L.Y. Lou, Y. Zhang, Y.J. Jia, Y. Li, H.F. Tian, Y.J. Cai, and C.X. Li, High Speed Laser Cladded Ti-Cu-NiCoCrAlTaY Burn Resistant Coating and its Oxidation Behavior, Surf. Coat. Technol., 2020, 392, p 125697. https://doi.org/10.1016/j.surfcoat.2020.125697

H.X. Liu, X.W. Zhang, Y.H. Jiang, and R. Zhou, Microstructure and High Temperature Oxidation Resistance of in-situ Synthesized TiN/Ti3Al Intermetallic Composite Coatings on Ti6Al4V Alloy by Laser Cladding Process, J. Alloys Compd., 2016, 670, p 268-274.

Z. Liu, K.C. Chan, L. Liu, and S.F. Guo, Bioactive Calcium Titanate Coatings on a Zr-Based Bulk Metallic Glass by Laser Cladding, Mater. Lett., 2012, 82, p 67-70.

B. Li, H. Yang, R. Holmes, Z. Wei, S. Kano, and H. Abe, Microstructure Evolution and Mechanical Property of High Temperature Solid-State Diffusion Bonded Cr-Zry4 with and without a 316 SS Interlayer, Nucl. Mater. Energy, 2022, 32, p 101233. https://doi.org/10.1016/j.nme.2022.101233

T. Ohta, Y. Nakagawa, Y. Kaneno, H. Inoue, T. Takasugi, and W.Y. Kim, Microstructures and Mechanical Properties of NbCr2 and ZrCr2 Laves Phase Alloys Prepared by Powder Metallurgy, J. Mater. Sci., 2003, 38(4), p 657-665. https://doi.org/10.1023/A:1021807519728

S. Kanazawa, Y. Kaneno, H. Inoue, W.Y. Kim, and T. Takasugi, Microstructures and Defect Structures in ZrCr2 Laves Phase Based Intermetallic Compounds, Intermetallics, 2002, 10(8), p 783-792. https://doi.org/10.1016/S0966-9795(02)00057-2

H. Zhang, Y.Z. He, Y. Pan, Y.S. He, and K.S. Shin, Synthesis and Characterization of NiCoFeCrAl3 High Entropy Alloy Coating by Laser Cladding, Adv. Mater. Res., 2010, 97-101, p 1408-1411. https://doi.org/10.4028/www.scientific.net/AMR.97-101.1408

L. Zhang, C. Dong, C.S. Wang, and Q. Wang, Laser Cladding of Fe-B-Si Iron Base Amorphous Composite Materials on 45 Steel Surface, Trans. Mater. Heat Treat., 2012, 33(10), p 116-123.

Z.G. Zhang, Z.H. Feng, X.J. Jiang, X.Y. Zhang, M.Z. Ma, and R.P. Liu, Microstructure and Tensile Properties of Novel Zr-Cr Binary Alloys Processed by Hot Rolling, Mater. Sci. Eng. A, 2016, 652, p 77--83. https://doi.org/10.1016/j.msea.2015.11.045

M. Guerain, C. Duriez, J.L. Grosseau-Poussard, and M. Mermoux, Review of Stress Fields in Zirconium Alloys Corrosion Scales, Corros. Sci., 2015, 95, p 11-21. https://doi.org/10.1016/j.corsci.2015.03.004

B. Krebs, J. Desquines, V. Busser, D. Drouan, and O. Zanellato, Experimental Characterization of Zircaloy-4 Sheet Deformation During Combined Hydriding and Corrosion, J. Nucl. Mater., 2013, 435(1), p 41-48. https://doi.org/10.1016/j.jnucmat.2012.12.019

C. Meng, L. Yang, Y. Wu, J. Tan, W. Dang, X. He, and X. Ma, Study of the Oxidation Behavior of CrN Coating on Zr Alloy in Air, J. Nucl. Mater., 2019, 515, p 354-369. https://doi.org/10.1016/j.jnucmat.2019.01.006

M. Andritschky and P. Alpuim, Strength Measurements of Thin Brittle ZrO2 Coatings Produced by Magnetron Sputtering on Steel Substrates, Vacuum, 1997, 48(5), p 417-422. https://doi.org/10.1016/S0042-207X(97)00004-3

P.B. Bozzano, C. Ramos, F. Saporiti, P.A. Vázquez, R.A. Versaci, and C. Saragovi, Oxidation of the Hexagonal Zr(Cr0.4Fe0.6)2 Laves Phase, J. Nucl. Mater., 2004, 328(2), p 225-231.

L.L. Luo, L.F. Zou, D.K. Schreiber, D.R. Baer, S.M. Bruemmer, G.W. Zhou, and C.M. Wang, In-situ Transmission Electron Microscopy Study of Surface Oxidation for Ni-10Cr and Ni-20Cr Alloys, Scr. Mater., 2016, 114, p 129-132. https://doi.org/10.1016/j.scriptamat.2015.11.031

X. Peng, L. Li, and F. Wang, Application of AFM in a Study of the Selective Oxidation Behavior of Materials During the Early Oxidation Stage, Scr. Mater., 2009, 60(8), p 699-702. https://doi.org/10.1016/j.scriptamat.2008.12.056

J.J. Dai, J.Y. Zhu, C.Z. Chen, and F. Weng, High Temperature Oxidation Behavior and Research Status of Modifications on Improving High Temperature Oxidation Resistance of Titanium Alloys and Titanium Aluminides: A review, J. Alloys Compd., 2016, 685, p 784-798. https://doi.org/10.1016/j.jallcom.2016.06.212

R.E. Lobnig, H.P. Schmidt, K. Hennesen, and H.J. Grabke, Diffusion of Cations in Chromia Layers Grown on Iron-Base Alloys, Oxid. Met., 1992, 37(1), p 81-93.

A.H. Chokshi, Diffusion, Diffusion Creep and Grain Growth Characteristics of Nanocrystalline and Fine-Grained Monoclinic, Tetragonal and Cubic Zirconia, Scr. Mater., 2003, 48(6), p 791-796. https://doi.org/10.1016/S1359-6462(02)00519-5

M. Kilo, G. Borchardt, S. Weber, S. Scherrer, K. Tinschert, B. Lesage, and O. Kaïtasov, Cation Diffusion in Calcia Stabilized Zirconia (CSZ), Radiat. Eff. Defects Solids, 1999, 151(1-4), p 29-33. https://doi.org/10.1080/10420159908245933

M. Kilo, M.A. Taylor, C. Argirusis, G. Borchardt, B. Lesage, S. Weber, S. Scherrer, H. Scherrer, M. Schroeder, and M. Martin, Cation Self-Diffusion of 44Ca, 88Y, and 96Zr in Single-Crystalline Calcia- and Yttria-Doped Zirconia, J. Appl. Phys., 2003, 94(12), p 7547-7552. https://doi.org/10.1063/1.1628379

M.A. Taylor, M. Kilo, G. Borchardt, S. Weber, and H. Scherrer, 96Zr Diffusion in Polycrystalline Scandia Stabilized Zirconia, J. Eur. Ceram. Soc., 2005, 25(9), p 1591-1595.

J.C. Brachet, I. Idarraga-Trujillo, M.L. Flem, M.L. Saux, V. Vandenberghe, S. Urvoy, E. Rouesne, T. Guilbert, C. Toffolon-Masclet, M. Tupin, C. Phalippou, F. Lomello, F. Schuster, A. Billard, G. Velisa, C. Ducros, and F. Sanchette, Early Studies on Cr-Coated Zircaloy-4 as Enhanced Accident Tolerant Nuclear Fuel Claddings for Light Water Reactors, J. Nucl. Mater., 2019, 517, p 268-285. https://doi.org/10.1016/j.jnucmat.2019.02.018

Y.G. Bai and C.M. Liu, High Resolution Auger Electron Spectroscopy Analysis on Grain Boundaries of High Purity Fe-0.2%P-2%Cr-C Alloys, J. Northeast. Univ. (Nat. Sci.), 2013, 24(4), p 373-376.

A.G. Revesz and F.P. Fehlner, The Role of Noncrystalline Films in the Oxidation and Corrosion of Metals, Oxid. Met., 1981, 15(3), p 297-321. https://doi.org/10.1007/BF01058831

C. Corvalán Moya, M.J. Iribarren, N. Di Lalla, and F. Dyment, Grain Boundary Diffusion and Segregation of Cr in α-Zr, J. Nucl. Mater., 2008, 382(1), p 35-38. https://doi.org/10.1016/j.jnucmat.2008.09.011

E. Wierzbicka, K. Syrek, G.D. Sulka, M. Pisarek, and M. Janik-Czachor, The Effect of Foil Purity on Morphology of Anodized Nanoporous ZrO2, Appl. Surf. Sci., 2016, 388, p 799-804. https://doi.org/10.1016/j.apsusc.2016.02.178

Y. Wang, B. Chen, X.Z. Wang, M.J. Chen, S.L. Li, G.H. Bai, J.S. Li, and W.J. Gong, Evolution of Cr/Cr2O3 Interface in Cr-Coated Zirconium Alloy in High Temperature Steam, Corros. Sci., 2023, 217, p 111099. https://doi.org/10.1016/j.corsci.2023.111099

J.H. Huang, S.L. Zou, W.W. **ao, C. Yang, H.X. Yu, L. Zhang, and K. Zhang, Microstructural Evolution of Cr-Coated Zr-4 Alloy Prepared by Multi-arc Ion Plating During High Temperature Oxidation, J. Nucl. Mater., 2022, 562, p 153616.

Acknowledgment

The authors appreciate the financial support for this work from Tian** Natural Science Foundation (No. 22JCYBJC01650), 145 Project, NSFC (52130509), Tian** Education Committee (No. 2020KJ108).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, W., Lou, LY., Liu, KC. et al. Structure and Oxidation Behavior of a Chromium Coating on Zr Alloy Cladding Tubes Deposited by High-Speed Laser Cladding. J Therm Spray Tech 33, 246–259 (2024). https://doi.org/10.1007/s11666-023-01698-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-023-01698-9