Abstract

Al2O3-YAG amorphous ceramic coating is expected to apply to harsh wear service due to its excellent crack propagation resistance, but the crystallization of this coating may affect its service stability. Therefore, the crystallization behavior of the Al2O3-YAG coating prepared by atmospheric plasma spray (APS) was investigated in this study. The results showed that this coating had excellent microstructure stability over a broad temperature range and had a higher activation energy during non-isothermal crystallization process. The isothermal DSC curves showed that the crystallization process of this coating was controlled by the change in external thermodynamic conditions. The grain growth mechanism for α-Al2O3 and YAG was from three-dimensional direction bulk growth to one-dimensional direction flake thickening. The calculated fragility index showed that the amorphous ceramic coating had better stability and higher plastic deformation capacity than other typical brittle materials at its critical temperature range.

Similar content being viewed by others

References

C.-P. Jiang, Y.-Z. **ng, F.-Y. Zhang and J.-M. Hao, Microstructure and Corrosion Resistance of Fe/Mo Composite Amorphous Coatings Prepared by Air Plasma Spraying, Int. J. Min. Met. Mater., 2012, 19, p 657–662.

Y. Yang, C. Zhang, Y. Peng, Y. Yu and L. Liu, Effects of Crystallization on the Corrosion Resistance of Fe-based Amorphous Coatings, Corros. Sci., 2012, 59, p 10–19.

A. Singh, S.R. Bakshi, A. Agarwal and S.P. Harimkar, Microstructure and Tribological Behavior of Spark Plasma Sintered Iron-based Amorphous Coatings, Mater. Sci. Eng. A, 2010, 527, p 5000–5007.

G. Wang, Z. Huang, P. **ao and X. Zhu, Spraying of Fe-based Amorphous Coating with High Corrosion Resistance by HVAF, J. Manuf. Process., 2016, 22, p 34–38.

C. Zhang, R.Q. Guo, Y. Yang, Y. Wu and L. Liu, Influence of the Size of Spraying Powders on the Microstructure and Corrosion Resistance of Fe-based Amorphous Coating, Electrochim. Acta., 2011, 56, p 6380–6388.

A.L. Greer, Confusion by Design, Nat. (London), 1993, 366, p 303–304.

T. Egami, Atomistic Mechanism of Bulk Metallic Glass Formation, J. Non-Cryst. Solids., 2003, 317, p 30–33.

A. Inoue and A. Takeuchi, Recent Progress in Bulk Glassy, Nanoquasicrystalline and Nanocrystalline Alloys, Mater. Sci. Eng. A, 2004, 375–377, p 16–30.

Z. Zhou, L. Wang, D.Y. He, F.C. Wang and Y.B. Liu, Microstructure and Electrochemical Behavior of Fe-Based Amorphous Metallic Coatings Fabricated by Atmospheric Plasma Spraying, J. Therm. Spray Technol., 2010, 20, p 344–350.

S.D. Zhang, W.L. Zhang, S.G. Wang, X.J. Gu and J.Q. Wang, Characterisation of Three-dimensional Porosity in an Fe-based Amorphous Coating and its Correlation with Corrosion Behaviour, Corros. Sci., 2015, 93, p 211–221.

Z. Wang, X. Zhang, J. Cheng, J. Lin and Z. Zhou, Cavitation Erosion Resistance of Fe-Based Amorphous/Nanocrystal Coatings Prepared by High-Velocity Arc Spraying, J. Therm. Spray Technol., 2014, 23, p 742–749.

P. Gong, K. Yao and S. Zhao, Cu-alloying Effect on Crystallization Kinetics of Ti41Zr25Be28Fe6 Bulk Metallic Glass, J. Therm. Anal. Calorim., 2015, 121, p 697–704.

Y.T. Chen, S.H. Lin and W.H. Hsieh, Differential Scanning Calorimetric Determination of the Thermal Properties of Amorphous Co60Fe20B20 and Co40Fe40B20 Thin Films, Appl. Phys. Lett., 2013, 102, p 051905.

Y. Zhang, J. Chen, G.L. Chen and X.J. Liu, Glass Formation Mechanism of Minor Yttrium Addition in CuZrAl Alloys, Appl. Phys. Lett., 2006, 89, p 131904.

Y. Lu, Y. Huang, X. Wei and J. Shen, Close Correlation Between Transport Properties and Glass-forming Ability of an FeCoCrMoCBY Alloy System, Intermetallics, 2012, 30, p 144–147.

M. Salehi, S.G. Shabestari and S.M.A. Boutorabi, Nano-crystal Development and Thermal Stability of Amorphous Al–Ni–Y–Ce Alloy, J. Non-Cryst. Solids., 2013, 375, p 7–12.

X. Zhou, H. Zhou, Z. Zhao, R. Liu and Y. Zhou, A Study of Non-isothermal Primary Crystallization Kinetics and Soft Magnetic Property of Co65Fe4Ni2Si15B14 Amorphous Alloy, J. Alloys Compd., 2012, 539, p 210–214.

H.J. Kim and Y.J. Kim, Amorphous Phase Formation of the Pseudo-binary Al2O3–ZrO2 Alloy During Plasma Spray Processing, J. Mater. Sci., 1999, 34, p 29–33.

X. Song, T. Suhonen, C. Sun et al., Microstructure, Microhardness and Crystallization Behavior of Amorphous Al2O3-YSZ Coating prepared by Air Plasma Spraying, Surf. Rev. Lett., 2015, 22, p 1550047.

T. Chraska, Z. Pala, R. Mušálek, J. Medřický and M. Vilémová, Post-treatment of Plasma-Sprayed Amorphous Ceramic Coatings by Spark Plasma Sintering, J. Therm. Spray Technol., 2015, 24, p 637–643.

K. Yang, J. Rong, Y. Zhuang et al., Microstructure and High PV Wear Behavior of Novel Amorphous Al2O3-YAG Ceramic Coating Fabricated by Atmospheric Plasma Spraying, J. Therm. Spray Technol., 2019, 28, p 803–825.

K. Yang, J. Rong, J. Feng et al., In-situ fabrication of amorphous/eutectic Al2O3–YAG ceramic composite coating via atmospheric plasma spraying, J. Eur. Ceram. Soc., 2016, 36, p 4261–4267.

K. Yang, J. Rong, J. Feng et al., Excellent Wear Resistance of Plasma-sprayed Amorphous Al2O3–Y3Al5O12 Ceramic Coating, Surf. Coat. Technol., 2017, 326, p 96–102.

T.A. Parthasarathy, T.-I. Mah and K. Keller, Creep Mechanism of Polycrystalline Yttrium Aluminum Garnet, J. Am. Ceram. Soc., 1992, 75, p 1756–1759.

Y. Liu, Z.-F. Zhang, B. King, J. Halloran and R.M. Laine, Synthesis of Yttrium Aluminum Garnet from Yttrium and Aluminum Isobutyrate Precursors, J. Am. Ceram. Soc., 1996, 79, p 385–394.

J. Rong, K. Yang, Y. Zhuang et al., Non-isothermal Crystallization Kinetics of Al2O3-YAG Amorphous Ceramic Coating Deposited via Plasma Spraying, J. Am. Ceram. Soc., 2018, 101, p 2888–2900.

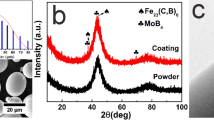

Z. Zhang, K. Yang, J. Rong et al., Study on Process Optimization of Sprayable Powders and Deposition Performance of Amorphous Al2O3-YAG Coatings, Coatings, 2020, 10, p 1158.

J. Medricky, F. Lukac, S. Csaki et al., Improvement of Mechanical Properties of Plasma Sprayed Al2O3-ZrO2-SiO2 Amorphous Coatings by Surface Crystallization, Materials., 2019, 12, p 3232.

M. Lasocka, The Effect of Scanning Rate on Glass Transition Temperature of Splat-cooled Te85Ge15, Mater. Sci. Eng. A, 1976, 23, p 173–177.

M. Avrami, Kinetics of Phase Change I General Theory, J. Chem. Phys., 1939, 7, p 1103–1112.

A. Melvin, Kinetics of Phase Change. II Transformation-Time Relations for Random Distribution of Nuclei, J. Chem. Phys., 1940, 8, p 212–224.

J. Málek, The Applicability of Johnson-Mehl-Avrami Model in the Thermal Analysis of the Crystallization Kinetics of Glasses, Thermochim. Acta., 1995, 267, p 61–73.

H.E. Kissinger, Reaction Kinetics in Differential Thermal Analysis, Anal. Chem., 1957, 29, p 1702–1706.

T. Ozawa, Kinetics of Non-isothermal Crystallization, Polymer, 1971, 12, p 150–158.

S. Saraswat, N. Mehta and S.D. Sharma, Applicability of Augis-Bennett Relation for Determination of Activation Energy of Glass Transition in Some Se rich Chalcogenide Glasses, J. Mater. Res. Technol., 2016, 5, p 111–116.

J.T. Zhang, W.M. Wang, H.J. Ma et al., Isochronal and Isothermal Crystallization Kinetics of Amorphous Fe-based Alloys, Thermochim. Acta., 2010, 505, p 41–46.

P. Gong, S. Zhao, X. Wang and K. Yao, Non-isothermal Crystallization Kinetics and Glass-forming Ability of Ti41Zr25Be28Fe6 Bulk Metallic Glass Investigated by Differential Scanning Calorimetry, Appl. Phys. A., 2015, 120, p 145–153.

A.T. Patel and A. Pratap, Kinetics of Crystallization of Zr52Cu18Ni14Al10Ti6 Metallic Glass, J. Therm. Anal. Calorim., 2011, 107, p 159–165.

T. Ozawa, A New Method of Analyzing Thermogravimetric Data, Bull. Chem. Soc. Jpn., 1965, 38, p 1881–1886.

J. Blazquez, C. Conde and A. Conde, Non-isothermal Approach to Isokinetic Crystallization Processes: Application to the Nanocrystallization of HITPERM Alloys, Acta Mater., 2005, 53, p 2305–2311.

J.W. Christian, The Theory of Transformations in Metals and Alloys: An Advanced Text in Physical Metallurgy[M], Pergamon Press, UK, 1965.

S. Ranganathan and M. Heimendahl, The Three Activation Energies with Isothermal Transformations Applications to Metallic Glasses, J. Mater. Sci., 1981, 16, p 2401–2404.

J. Hyun Na, M.D. Demetriou and W.L. Johnson, Fragility of Iron-based Glasses, Appl. Phys. Lett., 2011, 99, p 161902.

C.A. Angell, Formation of Glasses From Liquids and Biopolymers, Science, 1995, 267, p 1924–1935.

C.A. Angell, Relaxation in Liquids, Polymers and Plastic Crystals — Strong Fragile Patterns and Problems, J. Non-Cryst. Solids., 1991, 131, p 13–31.

H.E. Atyia and A.S. Farid, Non-isothermal Crystallization Kinetics of Ternary Se90Te10−x Pbx Glasses, J. Cryst. Growth., 2016, 436, p 125–133.

I.S. Ram and K. Singh, Study of Glass-Transition Kinetics of Pb-Modified Se80In20 System by Using Non-isothermal Differential Scanning Calorimetry, Int. J. Thermophys., 2013, 35, p 123–135.

D.N. Perera, Compilation of the Fragility Parameters for Several Glass-forming Metallic Alloys, J. Phys. Conden. Matter., 1999, 11, p 3807.

Acknowledgments

This research is jointly supported by Sub-project of Key Basic Research Projects of Basic Strengthening Program (Grant No. 172-04), National Nature Science Foundation of China (Grant No. 51772311) and Youth Innovation Promotion Association, Chinese Academy of Sciences (Grant No. 2016230).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Z., Yang, K., Ai, Y. et al. Crystallization Behavior of Novel Al2O3-YAG Amorphous Ceramic Coating Deposited by Atmospheric Plasma Spraying. J Therm Spray Tech 31, 462–476 (2022). https://doi.org/10.1007/s11666-022-01337-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-022-01337-9