Abstract

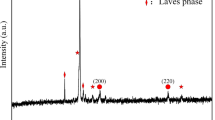

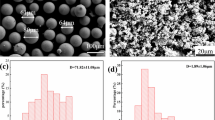

Recently, laser cladding has been widely investigated for the preparation of Co-based coatings for high-temperature applications. However, there is a highly cracking tendency in Co-based alloys due to the reinforcing hard phases. In this work, a single layer of CoCrMoSi coating was prepared with laser cladding on 304 stainless steel. By proper preheating, cracking was avoided during deposition. The high-temperature wear behaviors of the coating were evaluated by ball-on-disk test. In terms of morphology and chemical composition, the coating exhibited a gradient microstructure across the section. From the interface with the substrate to the top surface, the structure was characterized with three types of morphology in sequence, i.e., coarse cellular crystals in the interdiffusion zone, nanosized lamellar eutectic and Laves-phase dendrites embedded within nanosized lamellar eutectic. The surface hardness of the coating is 835HV0.3, which was mainly attributed to the Laves phase. Compared with the 304 stainless steel, the volume loss of the coating decreased by 76.5%at 400°C. The wear mechanisms of the coating were oxidation wear and abrasive wear. The excellent coating wear resistance at high-temperature can be traced to the microstructure of Laves phase embedded within the nanosized eutectic.

Similar content being viewed by others

References

D. Herzog, V. Seyda, E. Wycisk and C. Emmelmann, Additive manufacturing of metals, Acta Mater., 2016, 117, p 371–392.

A. Pascu, J.M. Rosca and E.M. Stanciu, Laser cladding: from experimental research to industrial applications, Mater. Today Proceed., 2019, 19, p 1059–1065.

E. Toyserkani, A. Khajepour, S.F. Corbin, Laser Cladding, CRC Press, (2004)

S.R. Lewis, R. Lewis and D.I. Fletcher, Assessment of laser cladding as an option for repairing/enhancing rails, Wear, 2015, 330, p 581–591.

Q. Liu, M. Janardhana, B.R.W. Hinton, M. Brandt and K. Sharp, Laser cladding as a potential repair technology for damaged aircraft components, Int. J. Struct. Integr., 2013, 2(3), p 314–331.

M. Brandt, S. Sun, N.R. Alam, P.J. Bendeich and A.P. Bishop, Laser cladding repair of turbine blades in power plants: from research to commercialisation, Inter. Heat Treat Surf. Eng., 2013, 3(3), p 105–114.

J. Leunda, C. Soriano, C. Sanz and V.G. Navas, Laser cladding of vanadium-carbide tool steels for die repair, Phys. Proced., 2011, 12, p 345–352.

Q.C. Liu, P.S. Baburamani, W. Zhuang, D. Gerrard, B.R.W. Hinton, M. Janardhana, K. Sharp, Surface modification and repair for aircraft life enhancement and structural restoration, Mater. Sci. Forum, 763-66 (2010)

W.C. Lin and C. Chen, Characteristics of thin surface layers of cobalt-based alloys deposited by laser cladding, Surf. Coat Technol., 2006, 200(14), p 4557–4563.

A. Renz, B. Prakash, J. Hardell and O. Lehmann, High-temperature sliding wear behaviour of Stellite®12 and Tribaloy®T400, Wear, 2018, 402–403, p 148–159.

E.M. do Nascimento, L.M. do Amaral, A.S.C.M. D'Oliveira, Characterization and wear of oxides formed on CoCrMoSi alloy coatings. Surf. Coat Technol., 332, 408-13 (2017)

C.R.C. Lima, M.J.X. Belém, H.D.C. Fals, C.A.D. Rovere, Wear and corrosion performance of stellite 6® coatings applied by HVOF spraying and GTAW hotwire claddin. J. Mater. Process Technol., 284, 116734 (2020)

R.A. Seraj, A. Abdollah-zadeh, S. Dosta, H. Assadi and I.G. Cano, Comparison of Stellite coatings on low carbon steel produced by CGS and HVOF spraying, Surf. Coat Technol., 2019, 372, p 299–311.

A.E. Yaedu and A.S.C.M. D’Oliveira, Cobalt based alloy PTA hardfacing on different substrate steels, Mater. Sci. Technol., 2005, 21(4), p 459–466.

E. Díaz, J.M. Amado, J. Montero, M.J. Tobar and A. Yáñez, Comparative study of co-based alloys in repairing low Cr-Mo steel components by laser cladding, Phys. Proced., 2012, 39, p 368–375.

F. Shu, Y. Tian, J. Zhou, W. He, H. Zhao and B. Xu, Microstructure and mechanical properties of two-layer laser-cladded CO-based coatings, J. Therm. Spray Technol., 2019, 28(6), p 1330–1338.

M.J. Tobar, J.M. Amado, C. Álvarez, A. García, A. Varela and A. Yáñez, Characteristics of tribaloy T-800 and T-900 coatings on steel substrates by laser cladding, Surf. Coat Technol., 2008, 202(11), p 2297–2301.

J. Przybylowicz and J. Kusinski, Laser cladding and erosive wear of Co-Mo-Cr-Si coatings, Surf. Coat Technol., 2000, 125(1), p 13–18.

C. Navas, M. Cadenas, J.M. Cuetos and J. de Damborenea, Microstructure and sliding wear behaviour of tribaloy T-800 coatings deposited by laser cladding, Wear, 2006, 260(7), p 838–846.

W. Ya, B. Pathiraj, D.T.A. Matthews, M. Bright and S. Melzer, Cladding of Tribaloy T400 on steel substrates using a high power Nd:YAG laser, Surf. Coat Technol., 2018, 350, p 323–333.

Acknowledgment

Financial support from National Key Research and Development Program of China (Grant No. 2016YFB1100200), Natural Science Foundation of China (Grant No. 51501120), Suzhou Science and Technology Program (SGC201720) is acknowledged. The authors thank Mr. Zongyuan Liu, Mr. Chuanbing Zou for assistance in sample preparation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is an invited paper selected from presentations at the 10th Asian Thermal Spray Conference (ATSC 2020) and has been expanded from the original presentation. ATSC 2020 was held in Ningbo, China, from November 1-3, 2020 and was organized by the Asian Thermal Spray Society with Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences as the Host Organizer.

Rights and permissions

About this article

Cite this article

Lu, H., Li, W., Qin, E. et al. The Gradient Microstructure and High-Temperature Wear Behavior of the CoCrMoSi Coating by Laser Cladding. J Therm Spray Tech 30, 968–976 (2021). https://doi.org/10.1007/s11666-021-01184-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-021-01184-0