Abstract

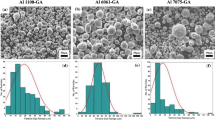

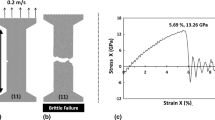

Aerosol deposition (AD) is a solid-state deposition technology that has been developed to fabricate ceramic coatings nominally at room temperature. Sub-micron ceramic particles accelerated by pressurized gas impact, deform, and consolidate on substrates under vacuum. Ceramic particle consolidation in AD coatings is highly dependent on particle deformation and bonding; these behaviors are not well understood. In this work, atomistic simulations and in situ micro-compressions in the scanning electron microscope, and the transmission electron microscope (TEM) were utilized to investigate fundamental mechanisms responsible for plastic deformation/fracture of particles under applied compression. Results showed that highly defective micron-sized alumina particles, initially containing numerous dislocations or a grain boundary, exhibited no observable shape change before fracture/fragmentation. Simulations and experimental results indicated that particles containing a grain boundary only accommodate low strain energy per unit volume before crack nucleation and propagation. In contrast, nearly defect-free, sub-micron, single crystal alumina particles exhibited plastic deformation and fracture without fragmentation. Dislocation nucleation/motion, significant plastic deformation, and shape change were observed. Simulation and TEM in situ micro-compression results indicated that nearly defect-free particles accommodate high strain energy per unit volume associated with dislocation plasticity before fracture. The identified deformation mechanisms provide insight into feedstock design for AD.

Similar content being viewed by others

Notes

It is believed that the order of magnitude difference in compression rate is not large enough to introduce substantial effects. Experimental measurements from large particle #1 (LP1), subjected to the higher compression rate of 0.03 s-1 were in-line with values from other large particles.

Here we use the term “fracture” in a general sense. It is unclear whether the observed event was truly fracture (i.e., no atomic bonds) as opposed to amorphization or crystallographic rotation in the center of the particles. Analysis showed the stress parallel to the compression axis at the center of both NPs decreased shortly after void nucleation, suggesting that subsequent fracture may have occurred and relieved the stress.

The displacement bursts with apparent constant loads are a result of the control system failing to keep up with the rapidly collapsing particle, although these SEM micro-compression tests were performed in displacement control mode.

References

J. Akedo and H. Ogiso, Room Temperature Impact Consolidation (RTIC) of Ceramic Fine Powder on Aerosol Deposition, Proc. of the 2nd International Conference and Exhibition on Ceramic Interconnect and Ceramic Microsystems Technologies (CICMT), 2006.

J. Akedo, Room Temperature Impact Consolidation (RTIC) of Fine Ceramic Powder by Aerosol Deposition Method and Applications to Microdevices, JTTEE5, 2008, 17, p 181-198

J. Akedo, Aerosol Deposition of Ceramic Thick Films at Room Temperature Densification Mechanism of Ceramic Layers, J. Am. Ceram. Soc., 2006, 89, p 1834-1839

Y. Imanaka, N. Hayashi, M. Takenouchi, and J. Akedo, Technology for Embedding Capacitors on Printed Wiring Board Using Aerosol Deposition, Proc. of Ceramic Interconnect and Ceramic Microsystems Technologies, 2006.

Y. Imanaka, N. Hayashi, M. Takenouchi, and J. Akedo, Aerosol Deposition for Post-LTCC, J. Eur. Ceram. Soc., 2007, 27, p 2789-2795

J. Akedo, Aerosol Deposition Method for Fabrication of Nano Crystal Ceramic Layer—Novel ceramic coating with collision of fine powder at room temperature, Mater. Sci. Forum, 2004, 449-452, p 43-48

Y. Kawakami, H. Yoshikawa, K. Komagata, and J. Akedo, Powder Preparation for 0.5Pb(Ni1/3Nb2/3)O3-0.15PbZrO3-0.35PbTiO3 Thick Films by the Aerosol Deposition Method, J. Cryst. Growth., 2005, 275, p el295-el300

J. Akedo and M. Lebedev, Piezoelectric Properties and Poling Effect of Pb(Zr, Ti)O3 Thick Films Prepared for Microactuators by Aerosol Deposition, Appl. Phys. Lett., 2000, 77, p 1710-1712

S. Sugimoto, T. Maeda, R. Kobayashi, J. Akedo, M. Lebedev, and K. Inomata, Magnetic Properties of Sm-Fe-N Thick Film Magnets Prepared by the Aerosol Deposition Method, IEEE Trans. Magn., 2003, 39, p 2986-2988

S. Sugimoto, T. Maki, T. Kagotani, J. Akedo, and K. Inomata, Effect of Applied Field during Aerosol Deposition on the Anisotropy of Sm-Fe-N Thick Films, J. Magn. Magn. Mater., 2005, 290-291, p 1202-1205

D.M. Chun and S.H. Ahn, Deposition mechanism of dry sprayed ceramic particles at room temperature using a nano-particle deposition system, Acta Mater., 2011, 59, p 2693-2703

H. Park, J. Kwon, I. Lee, and C. Lee, Shock-induced plasticity and fragmentation phenomena during alumina deposition in the vacuum kinetic spraying process, Scr. Mater., 2015, 100, p 44-47

M. Schubert, J. Exner, and R. Moos, Influence of Carrier Gas Composition on the Stress of Al2O3 Coatings Prepared by Aerosol Deposition Method, Materials, 2014, 7, p 5633-5642

D.W. Lee and S.M. Nam, Factors affecting surface roughness of Al2O3 films deposited on Cu substrates by an aerosol deposition method, J. Ceram. Process. Res., 2010, 11, p 100-106

S.H. Cho and Y.J. Yoon, Multi-layer TiO2 films prepared by aerosol deposition method for dye-sensitized solar cells, Thin Solid Films, 2013, 547, p 91-94

Y.J. Heo, H.T. Kim, K.J. Kim, S. Nahm, Y.J. Yoon, and J. Kim, Enhanced heat transfer by room temperature deposition of AlN film on aluminum for a light emitting diode package, Appl. Therm. Eng., 2013, 50, p 799-804

J. Exner, P. Fuierer, and R. Moos, Aerosol Codeposition of Ceramics: Mixtures of Bi2O3-TiO2 and Bi2O3-V2O5, J. Am. Ceram. Soc., 2015, 98, p 717-723

V. Swamy, A. Kuznetsov, L.S. Dubrovinsky, P.F. McMillan, V.B. Prakapenka, G. Shen, and B.C. Muddle, Size-Dependent Pressure-Induced Amorphization in Nanoscale TiO2, Phys. Rev. Lett., 2006, 96, p 135702-135704

M. Chen, J.W. McCauley, and K.J. Hemker, Shock-Induced Localized Amorphization in Boron Carbide, Science, 2003, 299, p 1563-1566

G. Subhash, S. Maiti, P.H. Geubelle, and D. Ghosh, Recent Advances in Dynamic Indentation Fracture, Impact Damage and Fragmentation of Ceramics, J. Am. Ceram. Soc., 2008, 91, p 2777-2791

A. Montagne, S. Pathak, X. Maeder, and J. Michler, Plasticity and Fracture of Sapphire at Room Temperature: Load-Controlled Microcompression of Four Different Orientations, Ceram. Int., 2014, 40, p 2083-2090

A.R. Beaber, J.D. Nowak, O. Ugurlu, W.M. Mook, S.L. Girshick, R. Ballarini, and W.W. Gerberich, Smaller is Tougher, Philos. Mag., 2011, 91, p 1179-1189

W.W. Gerberich, J. Michler, W.M. Mook, R. Ghisleni, F. Ostlund, D.D. Stauffer, and R. Ballarini, Scale Effects for Strength, Ductility, and Toughness in “Brittle” Materials, J. Mater. Res., 2009, 24, p 898-906

W.W. Gerberich, W.M. Mook, M.J. Cordill, C.B. Carter, C.R. Perrey, J.V. Heberlein, and S.L. Girshick, Reverse Plasticity in Single Crystal Silicon Nanospheres, Int. J. Plast., 2005, 21, p 2391-2405

F. Ostlund, K. Rzepiejewska-Malyska, K. Leifer, L.M. Hale, Y. Tang, R. Ballarini, W.W. Gerberich, and J. Michler, Brittle-to-Ductile Transition in Uniaxial Compression of Silicon Pillars at Room Temperature, Adv. Funct. Mater., 2009, 19, p 2439-2444

G. Xu and C. Zhang, Analysis of Dislocation Nucleation from a Crystal Surface Based on the Peierls-Nabarro Dislocation Model, J. Mech. Phys. Solids, 2003, 51, p 1371-1394

P.R. Howie, S. Korte, and W.J. Clegg, Fracture Modes in Micropillar Compression of Brittle Crystals, J. Mater. Res., 2012, 27, p 141-151

F. Ostlund, P.R. Howie, R. Ghisleni, S. Korte, K. Leifer, W.J. Clegg, and J. Michler, Ductile-Brittle Transition in Micropillar Compression of GaAs at Room Temperature, Philos. Mag., 2011, 91, p 1190-1199

S. Blonski and S.H. Garofalini, Molecular Dynamics Study of Silica-Alumina Interfaces, J. Phys. Chem., 1996, 100, p 2201-2205

D.A. Litton and S.H. Garofalini, Modeling of Hydrophilic Wafer Bonding by Molecular Dynamics Simulations, J. Appl. Phys., 2001, 89, p 6013-6023

Hysitron I, SEM Picoindenter User Manual. Revision 9.3.0913 edn., 2013

K. Hattar, D.C. Bufford, and D.L. Buller, Concurrent in Situ Ion Irradiation Transmission Electron Microscope, Nucl. Instrum. Methods Phys. Res. B, 2014, 338, p 56-65

N.I. Tymiak and W.W. Gerberich, Initial Stages of Contact-Induced Plasticity in Sapphire. I. Surfaces Traces of Slip and Twinning, Philos. Mag., 2007, 87, p 5143-5168

N.I. Tymiak and W.W. Gerberich, Initial Stages of Contact-Induced Plasticity in Sapphire. II. Mechanisms of Plasticity Initiation, Philos. Mag., 2007, 87, p 5169-5188

R. Nowak, T. Sekino, and K. Niihara, Surface Deformation of Sapphire Crystal, Philos. Mag. A, 1996, 74, p 171-194

J.D. Clayton, A Continuum Description of Nonlinear Elasticity, Slip and Twinning, with Application to Sapphire, Proc. R. Soc. A., 2009, 465, p 307-344

E.R. Dobrovinskaya, L.A. Lytvynov, and V. Pishchik, Properties of Sapphire, Sapphire, Springer, Boston, MA, 2009

Materials Science and Engineering Serving Society, R.P.H. Chang, R. Roy, M. Doyama, and S. Somiya, Ed., Elsevier Science, The Netherlands, 1998

Acknowledgments

B.L. Boyce, K. Hattar, and D.C. Bufford were supported by the Department of Energy (DOE) office of Basic Energy Sciences, Materials Science and Engineering. The authors acknowledge Sumitomo Chemical Co., LTD for supplying the alumina particles. We are grateful to C.B. Carter, P. Clem, D. Hirschfeld, H. Brown-Shaklee, R.D. Murphy, R. Tandon, and E.D. Reedy for valuable discussions. This work was performed, in part, at the Center for Integrated Nanotechnologies (CINT), an Office of Science User Facility operated for the U.S. DOE Office of Science. This work is supported by the Laboratory Directed Research and Development program at Sandia National Laboratories, a multi-program laboratory managed and operated by Sandia Corporation, a wholly owned subsidiary of Lockheed Martin Corporation, for the U.S. DOE’s National Nuclear Security Administration under contract DE-AC04-94AL85000.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the 2015 International Thermal Spray Conference, held May 11-14, 2015, in Long Beach, California, USA, and has been expanded from the original presentation.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary material 1 (MOV 3194 kb)

Supplementary material 2 (MOV 2198 kb)

Rights and permissions

About this article

Cite this article

Sarobol, P., Chandross, M., Carroll, J.D. et al. Room Temperature Deformation Mechanisms of Alumina Particles Observed from In Situ Micro-compression and Atomistic Simulations. J Therm Spray Tech 25, 82–93 (2016). https://doi.org/10.1007/s11666-015-0295-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-015-0295-2