Abstract

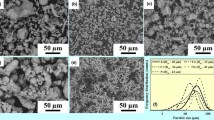

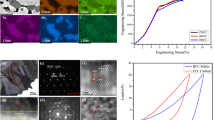

Al10Cr25Co20Ni25Fe20 high-entropy alloys (HEA) with ultrafine grains was synthesized through 30 h of mechanical alloying (MA). The morphological study of prepared high-entropy alloy powders was done by using scanning electron microscope images. Crystallite size and lattice strain of prepared high-entropy alloy were investigated through x-ray diffraction technique. Consolidation and sintering of HEA powders done by two methods such as conventional sintering and spark plasma sintering methods at 1000° and 1200 °C. After 30 h of MA, crystallite size 44 nm and lattice strain 0.182 was obtained. The mechanical properties analysis of high-entropy alloy was done in terms of its density, hardness measurements and compression test. For conventional sintering, the hardness values of 135 ± 6 HV0.5 for 1000 °C and 186 ± 8 HV0.5 for 1200 °C were obtained. For spark plasma sintering, the hardness values of 167 ± 5 HV0.5 for 1000 °C and 212 ± 6 HV0.5 for 1200 °C was obtained. Ultimate compressive strength for conventional sintering at 1000 °C and 1200 °C was 246 ± 5 MPa and 305 ± 6 MPa. Ultimate compressive strength of HEA for spark plasma sintered composite at 1000 °C and 1200 °C was 369 ± 5 MPa and 442 ± 5 MPa and the total elongation was 17.7%. BCC and FCC biphase mixture was obtained and confirmed by transmission electron microscopy images and electron backscattered diffraction analysis.

Similar content being viewed by others

References

J. Cao, B. Jiang, X. Cao, Z. Yuan, D. Yao, and J. Huang, High temperature oxidation resistance of an amorphous layer induced by ion implantation on the surface of Ni-based superalloy GH202, Appl. Surf. Sci., 2022, 586, p 152825. https://doi.org/10.1016/J.APSUSC.2022.152825

J. Cao, J. Zhang, R. Chen, Y. Ye, and Y. Hua, High temperature oxidation behavior of Nibased superalloy GH202, Mater Charact, 2016, 118, p 122–128. https://doi.org/10.1016/J.MATCHAR.2016.05.013

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang, Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes, Adv. Eng. Mater., 2004, 6, p 299–303. https://doi.org/10.1002/adem.200300567

B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent, Microstructural development in equiatomic multicomponent alloys, Mater. Sci. Eng. A, 2004, 375–377, p 213–218. https://doi.org/10.1016/j.msea.2003.10.257

B.S. Murty, J.W. Yeh, S. Ranganathan, P.P. Bhattacharjee, High-entropy alloys: basic concepts, in: B.S. Murty, J.W. Yeh, S. Ranganathan, P.P.B.T.-H.-E.A. (Second E. Bhattacharjee (Eds.), Elsevier, 2019: pp. 13–30.

O. Samoilova, N. Shaburova, A.O. Moghaddam, and E. Trofimov, Al0.25CoCrFeNiSi0.6 high entropy alloy with high hardness and improved wear resistance, Mater. Lett., 2022, 328, p 133190. https://doi.org/10.1016/j.matlet.2022.133190

B. Yin, Hu. **, and K. Chou, The effect of Ce addition on purification and inclusion modification of CoCrFeNiMn high entropy alloy, J. Alloy. Compd., 2023, 934, 167716. https://doi.org/10.1016/j.jallcom.2022.167716

X. Zhou, H. Dong, Y. Wang, and M. Yuan, Microstructure characteristics and mechanical performance of Fe-Cr-Ni- Al-Ti superalloy fabricated by powder metallurgy, J. Alloy. Compd., 2022, 918, 165612. https://doi.org/10.1016/j.jallcom.2022.165612

D. Yang, Y. Liu, T. Han, F. Zhou, Qu. Nan, M. Liao, Z. Lai, and J. Zhu, High thermal stability and oxidation behavior of FeCrNiAl-based medium-entropy alloys prepared by powder metallurgy, J. Alloy. Compd., 2022, 918, 165562. https://doi.org/10.1016/j.jallcom.2022.165562

A.S. Rogachev, S.G. Vadchenko, DYu. Kovalev, N.A. Kochetov, M. Zhukovskyi, T. Orlova, and A.S. Mukasyan, Long term stability of a high-entropy CoCrFeNiTi alloy fabricated by mechanical alloying, J. Alloy. Compd., 2023, 931, 167470. https://doi.org/10.1016/j.jallcom.2022.167470

H. Kalantari, M. Zandrahimi, M. Adeli, and H. Ebrahimifar, The production of nanocrystalline AlCoCrFeNiTiZn high entropy alloy via mechanical alloying: Study of the formation mechanism, microstructural evolution, and magnetic properties of the alloy, Intermetallics, 2022, 150, 107694. https://doi.org/10.1016/j.intermet.2022.107694

Q. Cheng, J. Chen, Yu. Gewen Yi, Y.G. Shan, J. Wang, and W. Wang, Comparative study of the microstructure and phase evolution of FeCoCrNiAl high-entropy alloy-matrix WC nanocomposite powders prepared by mechanical alloying, J. Alloy. Compd., 2023, 938, 168518. https://doi.org/10.1016/j.jallcom.2022.168518

M.R. Toroghinejad, F. Ebrahimi, and A. Shabani, Synthesis of the AlCrCuMnNi high entropy alloy through mechanical alloying and spark plasma sintering and investigation of its wear behavior, J. Mater. Res. Technol., 2022, 21, p 3262–3273. https://doi.org/10.1016/j.jmrt.2022.10.120

M.A. Karimi, M. Shamanian, M.H. Enayati, M. Adamzadeh and M. Imani, Fabrication of a novel magnetic high entropy alloy with desirable mechanical properties by mechanical alloying and spark plasma sintering, J. Manuf. Process., 2022, 84, p 859–870. https://doi.org/10.1016/j.jmapro.2022.10.048

Y. Fei Gao, L.H. Sun, J. Shen, W. Liu, M. Ba, and C. Deng, Microstructure and strengthening mechanisms of novel lightweight TiAlV05CrMo refractory high-entropy alloy fabricated by mechanical alloying and spark plasma sintering, J. Alloys Compd., 2023, 932, p 167659. https://doi.org/10.1016/j.jallcom.2022.167659

M.R. Toroghinejad, H. Pirmoradian, and A. Shabani, Synthesis of FeCrCoNiCu high entropy alloy through mechanical alloying and spark plasma sintering processes, Mater. Chem. Phys., 2022, 289, p 126433. https://doi.org/10.1016/j.matchemphys.2022.126433

H. Jain, Y. Shadangi, D. Chakravarty, A.K. Dubey, and N.K. Mukhopadhyay, High entropy steel processed through mechanical alloying and spark plasma sintering: alloying behaviour, thermal stability and mechanical properties, Mater. Sci. Eng. A, 2022, 856, p 144029. https://doi.org/10.1016/j.msea.2022.144029

A. Shahbazkhan, H. Sabet, and M. Abbasi, Microstructural and mechanical properties of NiCoCrAlSi high entropy alloy fabricated by mechanical alloying and spark plasma sintering, J. Alloy. Compd., 2022, 896, 163041. https://doi.org/10.1016/j.jallcom.2021.163041

A. Olejarz, W.Y. Huo, M. Zieliński, R. Diduszko, E. Wyszkowska, A. Kosińska, D. Kalita, I. Jóźwik, and M. Chmielewski, Microstructure and mechanical properties of mechanically-alloyed CoCrFeNi high-entropy alloys using low ball-to-powder ratio, J. Alloys Compd., 2023, 938, p 168196. https://doi.org/10.1016/j.jallcom.2022.168196

J.M. Torralba, P. Alvaredo, and A. García-Junceda, High-entropy alloys fabricated via powder metallurgy, Critic. Rev. Powder Metall., 2019, 62(2019), p 84–114. https://doi.org/10.1080/00325899.2019.1584454

C. Nagarjuna, S.K. Dewangan, H. Lee, K. Lee, and B. Ahn, Exploring the mechanical and tribological properties of AlCrFeNiTi high-entropy alloy fabricated by mechanical alloying and spark plasma sintering, Vacuum, 2023, 218, p 112611. https://doi.org/10.1016/j.vacuuam.2023.112611

K. Zhang and Fu. Zhengyi, Effect of annealing treatment on phase composition and microstructure of CoCrFeNiTiAlx high entropy alloys, Intermetallics, 2012, 22, p 24–32. https://doi.org/10.1016/j.intermet.2011.10.010

A. Shabani, M.R. Toroghinejad, and A. Shafyei, Log_e RE microstructure and mechanical properties of a multiphase FeCrCuMnNi high-entropy alloy, J. Mater. Eng. Perform., 2019, 28, p 2388–2398.

G.K. Williamson and W.H. Hall, x-Ray line broadening from field aluminum and wolfram, Acta Metall., 1953, 1(1), p 22–31.

Yu. Fei Gao, L.H. Sun, J. Shen, W. Liu, M. Ba, and C. Deng, Microstructural evolution and thermal stability in a nanocrystalline lightweight TiAlV0.5CrMo refractory high-entropy alloy synthesized by mechanical alloying, Mater. Lett., 2022, 329, p 133179. https://doi.org/10.1016/j.matlet.2022.133179

B. Ren, S. Li, N. Wang, Z. **ao, E. Axinte, and Y. Wang, Excellent catalytic performance of mechanically alloyed AlCrFeMnTiZr0.5 high-entropy alloy for malachite green degradation, Mater. Lett., 2023, 328, p 133076. https://doi.org/10.1016/j.matlet.2022.133076

H. Jain, Y. Shadangi, D. Chakravarty, A.K. Dubey, and N.K. Mukhopadhyay, High entropy steel processed through mechanical alloying and spark plasma sintering: alloying behavior, thermal stability and mechanical properties, Mater. Sci. Engg. A, 2022, 856, p 144029. https://doi.org/10.1016/j.msea.2022.144029

S. Mohanty, T.N. Maity, S. Mukhopadhyay, S. Sarkar, N.P. Gurao, and S. Bhowmick, Krishanu biswas, powder metallurgical processing of equiatomic AlCoCrFeNi high entropy alloy: microstructure and mechanical properties, Mater. Sci. Engg. A, 2017, 679, p 299–313. https://doi.org/10.1016/j.msea.2016.09.062

Fu. Zhiqiang, W. Chen, H. Wen, S. Morgan, F. Chen, B. Zheng, Y. Zhou, L. Zhang, and E.J. Lavernia, Microstructure and mechanical behavior of a novel Co20Ni20Fe20Al20Ti20 alloy fabricated by mechanical alloying and spark plasma sintering, Mater. Sci. Engg. A, 2015, 644, p 10–16. https://doi.org/10.1016/j.msea.2015.07.052

W. Ji, W. Wang, H. Wang, J. Zhang, Y. Wang, F. Zhang, and Fu. Zhengyi, Alloying behavior and novel properties of CoCrFeNiMn high-entropy alloy fabricated by mechanical alloying and spark plasma sintering, Intermetallics, 2015, 56, p 24–27. https://doi.org/10.1016/j.intermet.2014.08.008

D.K.V.D. Sudhansu Maharana, S.A. Prasad, M.S. Seetharaman, and T. Laha, Effect of sintering parameters on phase evolution, microstructural development and mechanical behavior of Ni46Al12Co18Cr8Fe12Mo4 high entropy alloy synthesized via mechanical alloying and spark plasma sintering, Mater. Sci. Engg. A, 2023, 886, p 145695. https://doi.org/10.1016/j.mesa.2023.145695

M. Zeraati, M.H.K. Feizabad, and G.R. Khayati, An investigation of the magnetic, mechanical, and kinetic characteristics of CuCrFeTiNi high entropy alloy by mechanical alloying and spark plasma sintering, J. Alloys Compd., 2023, 958, p 170347. https://doi.org/10.1016/j.jallcom.2023.170347

S. Praveen, B.S. Murty, and R.S. Kottada, Effect of molybdenum and niobium on the phase formation and hardness of nanocrystalline CoCrFeNi high entropy alloys, J. Nanosci. Nanotechnol., 2014, 14(10), p 8106–8109. https://doi.org/10.1166/jnn.2014.9441

Y. Liu, J. Wang, Q. Fang, B. Liu, Wu. Yuan, and S. Chen, Preparation of superfine-grained high entropy alloy by spark plasma sintering gas atomized powder, Intermetallics, 2016, 68, p 16–22. https://doi.org/10.1016/j.intermet.2015.08.012

A. Izci, B. Yavas, I. Antoniac et al., Investigation of the effects of spark plasma sintering parameters on equiatomic CoCrFeNiMo high entropy alloy, J. of Mater. Engg. and Perform., 2023 https://doi.org/10.1007/s11665-023-08872-8

A. Zhang, J. Han, J. Meng et al., Rapid preparation of AlCoCrFeN high entropy alloy by spark plasma sintering from elemental powder misxture, Mater. Lett., 2016, 181, p 82–85. https://doi.org/10.1016/j.matlet.2016.06.014

Acknowledgment

This research work was supported by the seed money grant (Grant No:1018/Registrar/2022-23/Date:10.10.2022) received from the Management of the Periyar Maniammai Institute of Science & Technology, Thanjavur, Tamil Nadu, India.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jeyasimman, D., Vijayaraghavan, V. & Venkateshwara, S. Synthesis and Characterization Study of Al10Cr25Co20Ni25Fe20 High-Entropy Alloy Powders through Mechanical Alloying. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09667-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09667-1