Abstract

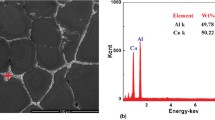

In this study, the impact of multistage solid solution treatment on the microstructure and properties of the Al-6.5Si-5.5Cu-0.2Zr-0.01Sr-0.06Ti-0.2Y alloy was examined using various experimental techniques such as optical microscopy, scanning electron microscopy, x-ray diffraction, transmission electron microscopy, and tensile testing. The findings demonstrated that with an increase in the multistage solid solution temperature and duration, the θ phase (stable Al2Cu) and intermetallic compounds gradually dissolved into the α-Al matrix, leading to a reduction in the residual phase content. The Si phase’s equivalent diameter decreased as the solid solution temperature increased, resulting in the spheroidization of eutectic Si, thereby contributing to dispersion strengthening. Consequently, the gradual rise in dislocation density and sample strength led to an enhancement in tensile strength. The G3 solid solution treatment (470 °C × 2 h + 480 °C × 2 h + 490 °C × 2 h + 500 °C × 2 h + 510 °C × 2 h + 520 °C × 14 h) demonstrated optimal mechanical properties with the ultimate tensile strength reaching 353.58 MPa and a fracture elongation rate of 9.25%. Moreover, this treatment exhibited superior corrosion resistance, as evident from the intergranular corrosion with a maximum depth of 69.36 μm, an electrochemical corrosion potential of − 1.1895 V, and a corrosion current density of 1.9965 × 10−7 A/cm2.

Similar content being viewed by others

Data availability

The data used to support the findings of this study are available from the corresponding author upon request.

Reference

A. Wiengmoon, P. Sukchot, N. Tareelap, J.T.H. Pearce, and T. Chairuangsri, Effects of T6 Heat Treatment with Double Solution Treatment on Microstructure, Hardness and Corrosion Resistance of Cast Al-Si-Cu Alloy, Arch. Metall. Mater., 2015, 60, p 881.

H.C. Fang, H. Chao, and K.H. Chen, Effect of Recrystallization on Intergranular Fracture and Corrosion of Al-Zn-Mg-Cu-Zr Alloy, J. Alloys Compd., 2015, 622, p 166.

K.K. Sankaran, Metallurgy and Design of Alloys with Hierarchical Microstructures., 2017, p 385.

M. Okayasu, K. Ota, S. Takeuchi, H. Ohfuji, and T. Shiraishi, Influence of Microstructural Characteristics on Mechanical Properties of ADC12 Aluminum Alloy, Mater. Sci. Eng. A, 2014, 592, p 189.

L. **, K. Liu and X.G. Chen, Evolution of Dispersoids and their Effects on Elevated-Temperature Strength and Creep Resistance in Al-Si-Cu 319 Cast Alloys with Mn and Mo Additions, Mater. Sci. Eng. A, 2020, 770, p 138554.

P. Tang, W. Li, K. Wang, J. Du, X. Chen, Y. Zhao, and W. Li, Effect of Al-Ti-C Master Alloy Addition on Microstructures and Mechanical Properties of Cast Eutectic Al-Si-Fe-Cu Alloy, Mater. Des., 2017, 115, p 147.

S.D. Apelian, Die Soldering: Mechanism of the Interface Reaction Between Molten Aluminum Alloy and Tool Steel, Metall. Mater. Trans. B, 2002, 33, p 465–476.

A.M.A. Mohamed, F.H. Samuel, and S.A. Kahtani, Influence of Mg and Solution Heat Treatment on the Occurrence of Incipient Melting in Al-Si-Cu-Mg Cast Alloys, Mater. Sci. Eng. A Struct. Mater. Prop. Misrostruct. Process., 2012, 543, p 22–34.

I.L. Ferreira, D.J. Moutinho, L.G. Gomes, O.L. Rocha, and A. Garcia, Modeling and Experimental Analysis of Macrosegregation During Transient Solidification of a Ternary Al–6 wt% Cu–1 wt% Si Alloy, Philos. Mag. Lett., 2009, 89, p 769.

T.A. Costa, E.S. Freitas, M. Dias, C. Brito, N. Cheung, and A. Garcia, Monotectic Al–Bi–Sn Alloys Directionally Solidified: Effects of Bi Content, Growth Rate and Cooling Rate on the Microstructural Evolution and Hardness, J. Alloys Compd., 2015, 653, p 243.

C. Zhang, Z. Zhang, M. Liu, E. Bao, C. Liang, and G. Zhao, Effects of Single-and Multi-stage Solid Solution Treatments on Microstructure and Properties of As-Extruded AA7055 Helical Profile, Trans. Nonferrous Met. Soc. China, 2021, 31, p 1885.

T. Marlaud, A. Deschamps, F. Bley, W. Lefebvre, and B. Baroux, Influence of Alloy Composition and Heat Treatment on Precipitate Composition in Al–Zn–Mg–Cu Alloys, Acta Mater., 2010, 58, p 248.

P. Ij, Recent Developments in Light Alloys, Mater. Trans. JIM, 1996, 37, p 12.

A.M. Samuel, H.W. Doty, S. Valtierra, and F.H. Samuel, Relationship Between Tensile and Impact Properties in Al–Si–Cu–Mg Cast Alloys and their Fracture Mechanisms, Mater. Des., 2014, 53, p 938.

Y. Huang, J.D. Robson, and P.B. Prangnell, The Formation of Nanograin Structures and Accelerated Room-Temperature Theta Precipitation in a Severely Deformed Al–4 wt.% Cu Alloy, Acta Mater., 2010, 58, p 1643.

S. Tahamtan, A.F. Boostani, and H. Nazemi, Mechanical Properties and Fracture Behavior of Thixoformed, Rheocast and Gravity-Cast A356 Alloy, J. Alloys Compd., 2009, 468, p 107.

Q. Zhou, C. Li, T. Wang, X. Xu, and Y. Luo, Effect of Various Multi-stage Solution Treatments on the Microstructure and Properties of Cold-Extruded Al-9.74Zn-2.59 Mg-0.94Cu-0.2Zr-0.83Ti alloy, J. Mater. Res., 2022, 37, p 3731–3742.

W. **gtao and C. Jianzhong, Interaction Intensity of Alloying Elements and Its Application in As-Cast Aluminium Alloys With Rare Earth Additions, J. **’an Univ. Archit. Technol., 1993, 25, p 445–449.

J. Coutures, R. Verges, and M. Foex, Comparison of Solidification Temperatures of Different Rare Earth Sesquioxides; Effect of Atmosphere, Revue Internationale des Hautes Temperatures et des Refractaires, 1975, 12, p 181.

S.C. Hansen, Antimony modification of aluminum-silicon alloys. The University of Wisconsin-Madison (2000).

K.M. Youssef, R.O. Scattergood, K.L. Murty, and C.C. Koch, Nanocrystalline Al–Mg Alloy with Ultrahigh Strength and Good Ductility, Scr. Mater., 2006, 54, p 251.

X. Xu, H. Shao, J. Gao, K. Chen, and X. Cheng, Effect of SiC Film on Tensile Properties of Nanostructured Ti Produced by Compressive Deformation at Liquid-Nitrogen Temperature, Mater. Sci. Eng. A Struct. Mater. Prop. Misrostruct. Process., 2008, 493, p 195–201.

X. Xu, X. Xu, Z. Jiang, Z. Jiang, V. Tabie, V. Tabie, Q. Mao, Q. Mao, T. Zhang, and T. Zhang, Effect of SiCw Volume Fraction and Cold Pressure on Microstructure and Mechanical Properties of Aluminum Matrix Composites, Mater. Res. Express, 2019, 6, 126597.

X. Chen, D. **a, J. Zhang, G. Huang, and F. Pan, Ultrafine-Grained Al–Zn–Mg–Cu Alloy Processed Via Cross Accumulative Extrusion Bonding and Subsequent Aging: Microstructure and Mechanical Properties, J. Alloys Compd., 2020, 846, 156306.

C. Zhong-Wei and J. Wan-Qi, Effects of Mg on the Microstructure and Mechanical Property of Al-Si-Mg Casting Alloys, J. Mater. Sci. Eng., 2004, 22, p 647–652.

G. Riontino, S. Abis, and P. Mengucci, DSC Investigation of Natural Ageing in High-Copper AlCuMg Alloys, in International Conference Aluminium Alloys (2000).

M.J. Deakin, C. Massa, P. Mengucci, and G. Riontino, Investigation on Phase Transformations During Ageing in an AlCuMgAgZn Alloy, Mater. Sci. Forum, 1996, 217–222, p 759.

Y. Wang, Y. Lu, S. Zhang, H. Zhang, and Z. Chen, Characterization and Strengthening Effects of Different Precipitates in Al-7Si-Mg Alloy, J. Alloys Compd., 2021, 885, p 161028.

I.A. Luna, H.M. Molinar, M.C. Román, J.E. Bocardo, and M.H. Trejo, Improvement of the tensile Properties of an Al–Si–Cu–Mg Aluminum Industrial Alloy by Using Multi Stage Solution Heat Treatments, Mater. Sci. Eng. A, 2013, 561, p 1.

J. Li, Y. Zhang, X. Cao, Q. Zeng, Y. Zhuang, X. Qian, and H. Chen, Accelerated Discovery of High-Strength Aluminum Alloys by Machine Learning, Commun. Mater., 2020, 1, p 73.

S.X.W. Jiang, The Effects of Non-isothermal Aging on the Strength and Corrosion Behavior of Al-Zn-Mg-Cu Alloy, J. Alloys Compd. Interdiscip. J. Mater. Sci. Solid-state Chem. Phys., 2016, 681, p 57–65.

P. Guyot and L. Cottignies, Precipitation Kinetics, Mechanical Strength and Electrical Conductivity of AlZnMgCu Alloys, Acta Mater., 1996, 44, p 4161.

D. Liu, B. **ong, F. Bian, Z. Li, X. Li, Y. Zhang, F. Wang, and H. Liu, Quantitative Study of Precipitates in an Al-Zn-Mg-Cu Alloy Aged with Various Typical Tempers, Mater. Sci. Eng. A, 2013, 588, p 1.

F.A. Chyada, A.R. Jabur, and H.A. Alwan, Effect Addition of Graphene on Electrical Conductivity and Tensile Strength for Recycled Electric Power Transmission Wires, Energy Procedia, 2017, 119, p 121.

A. Matthiessen and M. von Bose, I. On the Influence of Temperature on the Electric Conducting Power of Metals, Philos. Trans. R. Soc. Lond., 1862, 152, p 1–27.

L. Liu, J. Jiang, B. Zhang, W. Shao, and L. Zhen, Enhancement of Strength and Electrical Conductivity for a Dilute Al-Sc-Zr Alloy Via Heat Treatments and Cold Drawing, J. Mater. Sci. Technol., 2019, 35, p 962.

P.K. Rout, M.M. Ghosh, and K.S. Ghosh, Microstructural, Mechanical and Electrochemical Behaviour of a 7017 Al–Zn–Mg Alloy of Different Tempers, Mater Charact, 2015, 104, p 49.

E.V. Bobruk, M.Y. Murashkin, V.U. Kazykhanov, and R.Z. Valiev, Aging Behavior and Properties of Ultrafine-Grained Aluminum Alloys of Al-Mg-Si System, Rev. Adv. Mater. Sci., 2012, 31, p 109.

M.Y. Murashkin, I. Sabirov, V.U. Kazykhanov, E.V. Bobruk, A.A. Dubravina, and R.Z. Valiev, Enhanced Mechanical Properties and Electrical Conductivity in Ultrafine-Grained Al Alloy Processed Via ECAP-PC, Springer, 2013.

A. Mohamed and F.H. Samuel, Influence of Mg and Solution Heat Treatment on the Occurrence of Incipient Melting in Al–Si–Cu–Mg Cast Alloys, Mater. Sci. Eng. A, 2012, 543, p 22.

R. Chen, Q. Xu, H. Guo, Z. **a, Q. Wu, and B. Liu, Modeling of Strain Hardening Behavior and Mechanical Properties of Al-7Si-Mg Cast Aluminum Alloys During Tensile Process, Acta Metall. Sin., 2017, 53, p 1110–1124.

W. Yingjun, L. Honglei, W. Guojun, D. Kaihui, S. Yingwei, and N.I. Dingrui, Investigation of Anodic Film on a Novel RE-containing Al-Alloy Al-Zn-Mg-Cu-Sc, J. Chin. Soc. Corros. Prot., 2020, 40, p 131.

Acknowledgments

Thanks are due to the financial support from the Key Projects of Equipment Pre-research Foundation of the Ministry of Equipment Development of the Central Military Commission of China (No:6140922010201) and the Key Projects of Research and Development of Zhenjiang (GY2018021).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, C., Xu, X., Zhou, Q. et al. Effect of Multistage Solid Solution Treatment on Microstructure and Properties of Al-6.5Si-5.5Cu-0.2Zr-0.01Sr-0.06Ti-0.2Y Alloy. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09336-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09336-3