Abstract

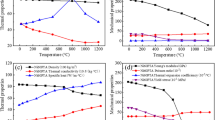

Induction cladding is a surface strengthening technique that integrates induction heating and cladding. However, the complex coupling effects of multiple physical fields make it challenging to establish the relationships between processing parameters and cladding quality. This study aims to determine the optimization strategy for induction cladding by considering the electrical parameter of loading frequency and structural parameter of coil clearance ratio. An orthogonal test was designed with loading frequencies at three temperature stages and three clearance ratios. Four indexes were tested, including cladding interface thermal stress, penetration zone (PZ) thickness ratio, phase transition zone (PTZ) thickness ratio, and heat-affected zone (HAZ) thickness ratio. Results showed loading frequency significantly affected interface thermal stress and PZ thickness while clearance ratio mainly influenced PTZ and HAZ thickness. The optimized processes on the condition of the numerical simulation were determined as: 0.05 coil clearance ratio, 25 kHz frequency at < 200 °C, 120 kHz at 200-800 °C, and 240 kHz at > 800 °C. This study provides a processing optimization method by tracking and adjusting time-varying sensitivity parameters for high-quality induction cladding. The strategy can be extended to other surface strengthening techniques involving complex coupling effects.

Similar content being viewed by others

References

J. Yu, S. Zhang, Y. Liu, and J. Wang, Numerical and Experimental Study of Stepwise Induction Cladding, Mater. Res. Express, 2021, 8(4), p 046501.

C. Meng, Z. Song, G. Wang, W. Zhuang, C. Wu, and X. Wang, Microstructure and Properties of CoCrFeNiCu High-Entropy Alloy Coating Prepared by Induction Cladding, Mater. Lett., 2022, 314, p 131896.

K. Wang, Y. Shi, X. Zhou, C. Zhai, Y. Guo, and J. Jiang, Microstructure and Properties of NiCrBSi Coating Formed by Ultrasonic Vibration Combined with Induction Cladding, Metall. Res. Technol., 2022, 119(2), p 205.

J. Dutkiewicz, Ł. Rogal, D. Kalita, J. Kawałko, M. S. Węglowski, K. Kwieciński, P. Śliwiński, H. Danielewski, B. Antoszewski, and E. Cesari, Microstructure, Mechanical Properties, and Martensitic Transformation in NiTi Shape Memory Alloy Fabricated Using Electron Beam Additive Manufacturing Technique, J. Mater. Eng. Perform., 2021, p 1-13.

B. Huang, S. Wu, Y. Gao, and L. Chen, Effect of Aging Treatment of Ni-Based/TiC Coatings by Induction Cladding, J. Mater. Eng. Perform., 2020, 29, p 5322–5328.

B. Huang, Y. Gao, P. Chen, W. **ong, and J. Tang, Microstructure and Properties of Ni+ B4C/Ti Coatings by High-Frequency Induction Cladding, Surf. Innov., 2018, 7(1), p 59–67.

Z. Song, S. Liu, X. Qiu, L. Zhang, C. Wu, X. Ren, X. Wang, and C. Meng, Effect of Ultrasonic Impact Treatment on the Properties of CoCrFeNiCu high-Entropy Alloy Coatings on Steel by Induction Cladding, Surf. Coat. Tech., 2023, 459, p 129390.

D. Wang, Q. Hu, and X. Zeng, Microstructures and Performances of Cr13Ni5Si2 Based Composite Coatings Deposited by Laser Cladding and LASER-Induction Hybrid Cladding, J. Alloys Compd., 2014, 588, p 502–508.

M. Wei, H. Yu, Z. Song, Y. Yin, X. Zhou, H. Wang, X. Ji, X. Li, P. Shi, and W. Zhang, Microstructural Evolution, Mechanical Properties and Wear Behavior of In-Situ TiC-Reinforced Ti Matrix Composite Coating by Induction Cladding, Surf. Coat. Tech., 2021, 412, p 127048.

H.L. Yu, W. Zhang, H.M. Wang, X.C. Ji, Z.Y. Song, X.Y. Li, and B.S. Xu, In-Situ Synthesis of TiC/Ti Composite Coating by High Frequency Induction Cladding, J. Alloys Compd., 2017, 701, p 244–255.

B. Huang, X. Wen, S. Zhang, H. Yu, X. **ao, and Y. Gao, Study on Microstructure and Properties of High Frequency Induction Cladding TiC/Ni Coating After Solution Treatment, Mater. Res. Express, 2019, 6(12), p 126405.

X. Chen, X. Qin, Z. Zhu, and K. Gao, Microstructural Evolution and Wear Properties of the Continual Local Induction Cladding NiCrBSi Coatings, J. Mater. Process. Tech., 2018, 262, p 257–268.

K.A. Skalomenos, M. Kurata, H. Shimada, and M. Nishiyama, Use of Induction-Heating in Steel Structures: Material Properties and Novel Brace Design, J. Constr. Steel Res., 2018, 148, p 112–123.

R. Sun, Y. Shi, Z. Pei, Q. Li, and R. Wang, Heat Transfer and Temperature Distribution during High-Frequency Induction Cladding of 45 Steel Plate, Appl. Therm. Eng., 2018, 139, p 1–10.

L. Zhang, C. Li, J. **e, and X. Xu, Analysis on Control Parameters of High-Frequency Induction Cladding Using Taguchi Method, J. Balk. Tribol. Assoc., 2016, 22, p 1873–1886.

Y. Yong, W. Fu, Q. Deng, and D. Chen, A Comparative Study of Vision Detection and Numerical Simulation for Laser Cladding of Nickel-Based Alloy, J. Manuf. Process., 2017, 28, p 364–372.

P. Farahmand and R. Kovacevic, Laser Cladding Assisted with an Induction Heater (LCAIH) of Ni–60% WC Coating, J. Mater. Process. Tech., 2015, 222, p 244–258.

X. Fu, B. Wang, X. Tang, H. Ji, and X. Zhu, Study on Induction Heating of Workpiece Before Gear Rolling Process with Different Coil Structures, Appl. Therm. Eng., 2017, 114, p 1–9.

M.T. Dalaee, L. Gloor, C. Leinenbach, and K. Wegener, Experimental and Numerical Study of the Influence of Induction Heating Process on Build Rates Induction Heating-Assisted Laser Direct Metal Deposition (IH-DMD), Surf. Coat. Tech., 2020, 384, p 125275.

D. Tong, J. Gu, and F. Yang, Numerical Simulation on Induction Heat Treatment Process of a Shaft Part: Involving Induction Hardening and Tempering, J. Mater. Process. Tech., 2018, 262, p 277–289.

Q.L. Xu, Y. Zhang, S.H. Liu, C.J. Li, and C.X. Li, High-Temperature Oxidation Behavior of CuAlNiCrFe High-Entropy Alloy Bond Coats Deposited using High-Speed Laser Cladding Process, Surf. Coat. Tech., 2020, 398, p 126093.

Acknowledgments

This study was supported by the Science Development Fund of Dongying [grant number DJB2022014].

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, C., Zhan, X., Fan, C. et al. Optimization of Induction Cladding Parameters Based on Parameter Sensitivity Analysis. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08851-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08851-z