Abstract

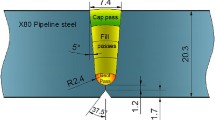

In the laboratory environment, it is possible to weld inclined pipes with an inclination angle of 30° or even larger angles and achieve good mechanical properties. However, in actual mountainous environments, it is difficult to achieve the same level of comprehensive performance as obtained in the laboratory. This study investigates X80 pipeline steel with different welding inclination angles welded in a mountainous environment by an oil and gas field company. The strain distribution of the welded joints of X80 pipeline steel is studied through microstructure observation, hardness testing, and digital image correlation (DIC) tensile testing. The DIC tensile test reveals that as the welding inclination angle increases, the microstrain at the moment of specimen fracture increases from 1,398,603 to 1,807,829. The microstrain at the moment of tensile fracture of the welded joint increases, the time at which strain concentration begins in the specimen advances, and the strain concentration rate and weld yield phenomenon increase, resulting in a decrease in tensile properties.

Similar content being viewed by others

Data Availability

All data, models, and code generated or used during the study appear in the submitted article.

References

G. Wang, Q. Cheng, W. Zhao, Q. Liao, and H. Zhang, Review on the Transport Capacity Management of Oil and Gas Pipeline Network: Challenges and Opportunities of Future Pipeline Transport, Energy Strategy Rev., 2022, 43, p 100933–100998.

O. Machhammer, C. Henschel, and A. Fussl, Natural Gas Pipelines for Hydrogen Transport, Chem. Ing. Tec., 2021, 93(4), p 717–728.

B. Wang, Y.C. Xu, J. Hu, S.F. Zhang, C.W. Cui, and H.X. Lan, The Analysis of Low Temperature Toughness on X80 Pipeline Steel Welded Joint, Transact. Indian Inst. Metals, 2018, 71(10), p 2517–2526.

H. Motohashi, N. Hagiwara, and T. Masuda, Tensile Properties and Microstructure of Weld Metal in MAG Welded X80 Pipeline Steel, Weld. Int., 2005, 19(2), p 100–108.

X. Wang, D. Wang, C. Deng, and C. Li, Effect of H2S Corrosion on the Fracture Toughness of the X80 Pipeline Steel Welded Joint, Materials, 2022, 15(13), p 4458.

M.P. Singh, K.S. Arora, R. Kumar, D.K. Shukla, and S. Siva Prasad, Influence of Heat Input on Microstructure and Fracture Toughness Property in Different Zones of X80 Pipeline Steel Weldments, Fatigue Fract. Eng. Mater. Struct., 2021, 44(1), p 85–100.

K. Xu, G.Y. Qiao, J.S. Wang, S.Y. Zhang, and F.R. **ao, Research on the Fatigue Properties of Sub-Heat-Affected Zones in X80 Pipe, Fatigue Fract. Eng. Mater. Struct., 2020, 43(12), p 2915–2927.

M.F. Ramirez, J.W. Hernández, D.H. Ladino, M. Masoumi, and H. Goldenstein, Effects of Different Cooling Rates on the Microstructure, Crystallographic Features, and Hydrogen Induced Cracking of API X80 Pipeline Steel, J. Mater. Res. Technol., 2021, 14(1848), p 1861.

J.A. Da Nóbrega, D.D. Diniz, A.A. Silva, T.M. Maciel, V.H.C. De Albuquerque, and J.M.R. Tavares, Numerical Evaluation of Temperature Field and Residual Stresses in an API 5L X80 Steel Welded Joint Using the Finite Element Method, Metals, 2016, 6(2), p 28.

J. Shen, P. Agrawal, T.A. Rodrigues, J.G. Lopes, N. Schell, Z. Zeng, R.S. Mishra, and J.P. Oliveira, Gas Tungsten Arc Welding of as-Cast AlCoCrFeNi2.1 Eutectic High Entropy Alloy, Mater. Design, 2022, 223, p 111176.

J. Shen, R. Gonçalves, Y.T. Choi, J.G. Lopes, J. Yang, N. Schell, H.S. Kim, and J.P. Oliveira, Microstructure and Mechanical Properties of Gas Metal Arc Welded CoCrFeMnNi Joints using a 410 Stainless Steel Filler Metal, Mater. Sci. Eng. A, 2022, 857, p 144025.

J. Shen, R. Gonçalves, Y.T. Choi, J.G. Lopes, J. Yang, N. Schell, H.S. Kim, and J.P. Oliveira, Microstructure and Mechanical Properties of Gas Metal Arc Welded CoCrFeMnNi Joints using a 308 Stainless Steel Filler Metal, Scripta Mater., 2023, 222, p 115053.

McVicker, Gail D. (2002) Mexico Pipeline Dubbed Project of Extremes: what’s the Purpose of All of this Cargo? To Provide Natural Gas Across Northern Baja California, Mexico. Underground Construction

C.E. Smith, US Agency Advises of Weld Failures on New Pipelines, Oil Gas J., 2010, 108(19), p 41–42.

Tajika, H.; Igi, S.; Sakimoto, T.; Ikeda, R.; Handa, T.; Kondo, J. (2018) Strain Capacity Investigation on Grade X70 High Strain Line Pipe with Girth Weld(Conference Paper). American Soc. Mech. Eng., Pressure Vessels Pi** Div (Publication) PVP, 6B: V06BT06A055

R.I. Suleimanov, L.Z. Zainagalina, M.Y. Khabibullin, L.M. Zaripova, and N.O. Kovalev, Studying Heat-Affected Zone Deformations of Electric Arc Welding, IOP Conf. Series: Mater Sci. Eng., 2018, 327(3), p 032053.

T.Q. Wu, J. Xu, M.C. Yan, C. Sun, C.K. Yu, and W. Ke, Synergistic Effect of Sulfate-Reducing Bacteria and Elastic Stress on Corrosion of X80 Steel in Soil Solution, Corr. Sci., 2014, 83, p 38–47.

J. **e, C. Cai, Y. Liang, Z. Liu, and Y. Ma, Microstructure and Mechanical Properties of Heat Affected Zone of Laser-MAG Hybrid Welded Low Carbon Bainitic Steel Joints, J. Opt. Laser Technol., 2022, 148, p 107729.

R. Chen, X. Hu, M. Zhu, and F. Xuan, In-situ Observation of Strain Evolution and Ratchetting of Growing Fatigue Cracks, J. Eng. Fract. Mech., 2023, 279, p 109041–109098.

R. Chen, M. Zhu, F. Xuan, S. Wu, and Y. Fu, Near-Tip Strain Evolution and Crack Closure of Growing Fatigue Crack under a Single Tensile Overload, Int. J. Fatigue, 2020, 134, p 105478.

S. Liu, M. Zhu, H. Zhou, D. Wan, and F. Xuan, Strain Visualization of Growing Short Fatigue Cracks in the Heat-Affected Zone of a Ni–Cr–Mo–V Steel Welded Joint: INTERGRANULAR Cracking and Crack Closure, Int. J. Pressure Vessels Pi**, 2019, 178, p 13.

J. Shen, P. Agrawal, T.A. Rodrigues, J.G. Lopes, N. Schell, J. He, Z. Zeng, R.S. Mishra, and J.P. Oliveira, Microstructure Evolution and Mechanical Properties in a Gas Tungsten arc Welded Fe42Mn28Co10Cr15Si5 Metastable High Entropy Alloy, Mater. Sci. Eng. A, 2023, 867, p 144722.

J.G. Lopes, P. Agrawal, J. Shen, N. Schell, R.S. Mishra, and J.P. Oliveira, Evolution of Microstructure and Mechanical Properties in Gas Tungsten arc Welded Dual-Phase Fe50Mn30Co10Cr10 High Entropy Alloy, Mater. Sci. Eng. A, 2023, 878, p 145233.

Acknowledgments

This research work was supported by the Natural Science Foundation of Sichuan Province of China (2022NSFSC0325) and application foundation project of Sichuan Science and Technology Department (No. 2021YJ0346).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lin, R., Feng, B., Liu, L. et al. Effect of Welding Inclination Angle on Strain Distribution of X80 Pipeline Steel Welded Joint in Mountain Environment. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08805-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08805-5