Abstract

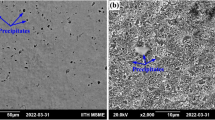

This study used laser additive manufacturing technology to fabricate austenitic–martensitic stainless steel functionally graded materials (ASS-MSS FGM). The microstructure and mechanical properties of ASS-MSS FGM were characterized, and the surface integrity after milling experiments of the ASS-MSS FGM was analyzed. The microstructure of the ASS-MSS FGM exhibited a dense subgrain structure with diverse subgrain types and no fixed growth direction. The microhardness of the ASS-MSS FGM increased from 283 HV to 530 HV due to the increased proportion of the martensitic phase. The ASS-MSS FGM tensile specimens fractured in the austenitic stainless steel region. The tensile strength is 896 MPa, which is increased by 121 MPa compared to ASS. The fracture elongation is 18%, which is increased by 140% compared to MSS. The milling experiments revealed that the degree of work hardening decreased by 8.1% along the building direction of the ASS-MSS FGM. Compared with the austenitic and martensitic layers, the degree and depth of work hardening of the gradient layer were in the transitional zone between them. The microstructure of ASS-MSS FGM after the milling mainly exhibited three deformation phenomena: grain squeezed deformation, grain broken dislodgement, and grain sheared fracture.

Similar content being viewed by others

References

W.E. Frazier, Metal Additive Manufacturing: A Review, J. Mater. Eng. Perform., 2014, 23(6), p 1917–1928.

T.D. Ngo, A. Kashani, G. Imbalzano, K.T.Q. Nguyen, and D. Hui, Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges, Compos. Part B Eng., 2018, 143, p 172–196.

A. Reichardt, R.P. Dillon, J.P. Borgonia, A.A. Shapiro, B.W. McEnerney, T. Momose, and P. Hosemann, Development and Characterization of Ti-6Al-4V to 304L Stainless Steel Gradient Components Fabricated with Laser Deposition Additive Manufacturing, Mater. Des., 2016, 104, p 404–413.

D.D. Singh, S. Arjula, and A.R. Reddy, Functionally Graded Materials Manufactured by Direct Energy Deposition: A Review, Mater. Today Proc., 2021, 47, p 2450–2456.

M.L. Dezaki, A. Serjouei, A. Zolfagharian, M. Fotouhi, M. Moradi, M.K.A. Ariffin, and M. Bodaghi, A Review on Additive/Subtractive Hybrid Manufacturing of Directed Energy Deposition (DED) Process, Adv. Powder Mater., 2022, 1(4), p 100054.

Z. Yan, K. Zou, M. Cheng, Z. Zhou, and L. Song, Revealing Relationships between Heterogeneous Microstructure and Strengthening Mechanism of Austenitic Stainless Steels Fabricated by Directed Energy Deposition (DED), J. Mater. Res. Technol., 2021, 15, p 582–594.

P. Bajaj, A. Hariharan, A. Kini, P. Kürnsteiner, D. Raabe, and E.A. Jägle, Steels in Additive Manufacturing: A Review of Their Microstructure and Properties, Mater. Sci. Eng. A, 2020, 772, p 138633.

Y. Yang, Y. Gong, C. Li, X. Wen, and J. Sun, Mechanical Performance of 316 L Stainless Steel by Hybrid Directed Energy Deposition and Thermal Milling Process, J. Mater. Process. Technol., 2021, 291, p 117023.

D. Kong, C. Dong, X. Ni, L. Zhang, J. Yao, C. Man, X. Cheng, K. **ao, and X. Li, Mechanical Properties and Corrosion Behavior of Selective Laser Melted 316L Stainless Steel after Different Heat Treatment Processes, J. Mater. Sci. Technol., 2019, 35(7), p 1499–1507.

D. Pathote, D. Jaiswal, V. Singh, and C.K. Behera, Electrochemical Corrosion Behavior of Tantalum Coated 316L Stainless Steel by D.C. Magnetron Sputtering for Orthopedic Applications, Appl. Surf. Sci. Adv., 2023, 13, p 100365.

A. Ascari, E.P. Zapico, V. Dimatteo, and A. Fortunato, Dissimilar Laser Welding of Copper and Stainless-Steel Thin Sheets for e-Mobility Applications, Procedia CIRP, 2022, 111, p 770–773.

B. Zheng, J.C. Haley, N. Yang, J. Yee, K.W. Terrassa, Y. Zhou, E.J. Lavernia, and J.M. Schoenung, On the Evolution of Microstructure and Defect Control in 316L SS Components Fabricated via Directed Energy Deposition, Mater. Sci. Eng. A, 2019, 764, p 138243.

L. Chechik, N.A. Boone, L.R. Stanger, P. Honniball, F. Freeman, G. Baxter, J.R. Willmott, and I. Todd, Variation of Texture Anisotropy and Hardness with Build Parameters and Wall Height in Directed-Energy-Deposited 316L Steel, Addit. Manuf., 2021, 38, p 101806.

K.U. Yazar, S. Pawar, K.S. Park, and S.H. Choi, Effect of Process Parameters on the Clad Morphology, Microstructure, Microtexture, and Hardness of Single Layer 316 L Stainless Steel during Direct Energy Deposition, Mater. Charact., 2022, 191, p 112148.

J.T. Pacheco, V.H. Meura, P.R.A. Bloemer, M.T. Veiga, O.C. de Moura Filho, A. Cunha, and M.F. Teixeira, Laser Directed Energy Deposition of AISI 316L Stainless Steel: The Effect of Build Direction on Mechanical Properties in As-Built and Heat-Treated Conditions, Adv. Ind. Manuf. Eng., 2022, 4, p 100079.

A. Saboori, G. Piscopo, M. Lai, A. Salmi, and S. Biamino, An Investigation on the Effect of Deposition Pattern on the Microstructure, Mechanical Properties and Residual Stress of 316L Produced by Directed Energy Deposition, Mater. Sci. Eng. A, 2020, 780, p 139179.

K. Moeinfar, F. Khodabakhshi, S.F. Kashani-bozorg, M. Mohammadi, and A.P. Gerlich, A Review on Metallurgical Aspects of Laser Additive Manufacturing (LAM): Stainless Steels, Nickel Superalloys, and Titanium Alloys, J. Mater. Res. Technol., 2022, 16, p 1029–1068.

M.K. Alam, M. Mehdi, R.J. Urbanic, and A. Edrisy, Mechanical Behavior of Additive Manufactured AISI 420 Martensitic Stainless Steel, Mater. Sci. Eng. A, 2020, 773, p 138815.

Y. Liu, J.X. Zhang, and L.J. Zhang, Microstructure Analysis of Martensite Stainless Steel by Directed Energy Deposition and Uniform High Hardness, J. Mater. Process. Technol., 2022, 300, p 117392.

W. Chen, B. **ao, L. Xu, Y. Han, L. Zhao, and H. **g, Additive Manufacturing of Martensitic Stainless Steel Matrix Composites with Simultaneously Enhanced Strength-Ductility and Corrosion Resistance, Compos. Part B Eng., 2022, 234, p 109745.

Y. Liu, A. Li, X. Cheng, S.Q. Zhang, and H.M. Wang, Effects of Heat Treatment on Microstructure and Tensile Properties of Laser Melting Deposited AISI 431 Martensitic Stainless Steel, Mater. Sci. Eng. A, 2016, 666, p 27–33.

C. Zhang, Y. Liu, J. Lu, L. Xu, Y. Lin, P. Chen, Q. Sheng, and F. Chen, Additive Manufacturing and Mechanical Properties of Martensite/Austenite Functionally Graded Materials by Laser Engineered Net Sha**, J. Mater. Res. Technol., 2022, 17, p 1570–1581.

R. Ghanavati, H. Naffakh-Moosavy, and M. Moradi, Additive Manufacturing of Thin-Walled SS316L-IN718 Functionally Graded Materials by Direct Laser Metal Deposition, J. Mater. Res. Technol., 2021, 15, p 2673–2685.

S.H. Kim, H. Lee, S.M. Yeon, C. Aranas, K. Choi, J. Yoon, S.W. Yang, and H. Lee, Selective Compositional Range Exclusion via Directed Energy Deposition to Produce a Defect-Free Inconel 718/SS 316L Functionally Graded Material, Addit. Manuf., 2021, 47, p 102288.

W. Fan, C. Zhang, H. Tan, Y. Wang, Y. Peng, F. Zhang, X. Lin, and W. Huang, Microstructures and Mechanical Properties of Invar/MnCu Functionally Graded Material Fabricated by Directed Energy Deposition, Mater. Sci. Eng. A, 2022, 860, p 144332.

N. Uçak, A. Çiçek, and K. Aslantas, Machinability of 3D Printed Metallic Materials Fabricated by Selective Laser Melting and Electron Beam Melting: A Review, J. Manuf. Process., 2022, 80, p 414–457.

H. Ding, B. Zou, X. Wang, J. Liu, and L. Li, Microstructure, Mechanical Properties and Machinability of 316L Stainless Steel Fabricated by Direct Energy Deposition, Int. J. Mech. Sci., 2023, 243, p 108046.

H. Ji, M.K. Gupta, Q. Song, W. Cai, T. Zheng, Y. Zhao, Z. Liu, and D.Y. Pimenov, Microstructure and Machinability Evaluation in Micro Milling of Selective Laser Melted Inconel 718 Alloy, J. Mater. Res. Technol., 2021, 14, p 348–362.

I.R. Ibrahim, M. Khedr, T.S. Mahmoud, H.A. Abdel-Aleem, and A. Hamada, Study on the Mechanical Performance of Dissimilar Butt Joints between Low Ni Medium-Mn and Ni-Cr Austenitic Stainless Steels Processed by Gas Tungsten Arc Welding, Metals (Basel), 2021, 11(9), p 1439.

K. Saeidi, X. Gao, Y. Zhong, and Z.J. Shen, Hardened Austenite Steel with Columnar Sub-Grain Structure Formed by Laser Melting, Mater. Sci. Eng. A, 2015, 625, p 221–229.

Acknowledgments

This work is supported by the National Natural Science Foundation of China (Grant nos. 52075276, 52105192), Special fund projects for guiding local scientific and technological development by the central government (YDZX2022016), and Major scientific and technological innovation projects of Shandong Province (Grant No. 2020CXGC011004).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Qu, H., Chen, H., Zhang, J. et al. Microstructure, Mechanical Properties, and Surface Integrity of Austenitic-Martensitic Stainless Steel Functionally Graded Materials Prepared by Laser Additive Manufacturing. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08757-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08757-w