Abstract

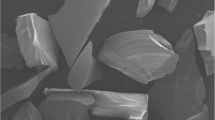

This research investigates the fabrication of porous mullite filter material from reaction sintered mullite grains for high-temperature applications. Current filter types are not suitable for application in high-temperature and corrosive environments despite their high porosity. Acicular Mullite Ceramics are known for their highly porous microstructures with excellent mechanical integrity. Fabrication of a rod-like porous mullite filter from mullite grains produced from pyrophyllite clay and Al2O3 via reaction sintering was investigated. Pure mullite phase was produced at 1600 °C, and the use of a binder and foaming agent helped to obtain a porous structure. Above 1700 °C, acicular mullite grain growth via two-dimensional heterogeneous nucleation was promoted. A friable and structurally poor material was produced at temperatures just below 1800 °C. Above 1800 °C, the structural integrity of the ceramic material was improved. The measured total porosity and average pore diameter at 1800 °C were 36.20% and 29.32 µm, respectively. The measured density was 1.99 g/cm3, and the average compressive strength was 12.60 MPa. The characteristic strength was 14.49 MPa, with a Weibull modulus of 2.67.

Similar content being viewed by others

References

A. Pyzik, R. Ziebarth, C. Han, and K. Yang, High-Porosity Acicular Mullite Ceramics for Multifunctional Diesel Particulate Filters, Int. J. Appl. Ceram. Technol., 2011, 8(5), p 1059–1066.

F. Zuo, S. Zhang, H. Liu, H. Fong, X. Yin, J. Yu, and B. Ding, Free-standing Polyurethane Nanofiber/Nets Air Filters for Effective PM Capture, Small., 2017, 13(46), p 1702139.

R. **ong, G. Sun, K. Si, Q. Liu, and K. Liu, Pressure Drop Prediction of Ceramic Membrane Filters at High Temperature, Powder Technol., 2020, 364, p 647–653.

K. He and L. Wang, A Review of Energy Use and Energy-Efficient Technologies for the Iron and Steel Industry, Renew. Sustain. Energy Rev., 2017, 70, p 1022–1039.

H. Wang, S. Lin, S. Yang, X. Yang, J. Song, D. Wang, H. Wang, Z. Liu, B. Li, and M. Fang, High-temperature Particulate Matter Filtration with Resilient Yttria-stabilized ZrO2 Nanofiber Sponge, Small, 2018, 14(19), p 1800258.

R. Zhang, C. Liu, P.-C. Hsu, C. Zhang, N. Liu, J. Zhang, H.R. Lee, Y. Lu, Y. Qiu, and S. Chu, Nanofiber Air Filters with High-Temperature Stability for Efficient PM2.5 Removal from the Pollution Sources, Nano Lett., 2016, 16(6), p 3642–3649.

S. Heidenreich, Hot Gas Filtration–A Review, Fuel, 2013, 104, p 83–94. https://doi.org/10.1016/j.fuel.2012.07.059

A.R. Barron, “H. Schneider, K. Okada, and J. Pask. Mullite and Mullite Ceramics Wiley, Chichester, 1994, ISBN 0‐471‐94249‐9. In: Advanced Materials for Optics and Electronics, Wiley 1995. pp 251

B.A. Latella, L. Henkel, and E.G. Mehrtens, Permeability and High Temperature Strength of Porous Mullite-Alumina Ceramics for Hot Gas Filtration, J. Mater. Sci., 2006, 41(2), p 423–430.

E.H. Tanabe, P.M. Barros, K.B. Rodrigues, and M.L. Aguiar, Experimental Investigation of Deposition and Removal of Particles during Gas Filtration with Various Fabric Filters, Sep. Purif. Technol., 2011, 80(2), p 187–195.

K.-S. Lee, J.-R. Sohn, and Y.-O. Park, Filtration Performance Characteristics of Ceramic Candle Filter Based on Inlet Structure of High-Temperature and High-Pressure Dust Collectors, J. Ind. Eng. Chem., 2015, 21, p 101–110.

Y.-S. Chen, C.-J. Hsu, S.-S. Hsiau, and S.-M. Ma, Clean Coal Technology for Removal Dust Using Moving Granular Bed Filter, Energy, Elsevier, 2017, 120, p 441–449.

F. Wang, S. Hao, B. Dong, N. Ke, N.Z. Khan, L. Hao, L. Yin, X. Xu, and S. Agathopoulos, Porous-Foam Mullite-Bonded SiC-Ceramic Membranes for High-Efficiency High-Temperature Particulate Matter Capture, J. Alloys Compd., 2022, 893, p 162231.

I.S. Hwang, J.-T. Park, and Y.L. Lee, Feasibility of a Porous Ceramic Filter for Collecting Brake Fine Dust, Int. J. Automot. Technol., 2022, 23(2), p 521–527.

S. Li, H. Du, A. Guo, H. Xu, and D. Yang, Preparation of Self-Reinforcement of Porous Mullite Ceramics through in Situ Synthesis of Mullite Whisker in Flyash Body, Ceram. Int., 2012, 38(2), p 1027–1032.

A. Barron, H. Scheinder, K. Okada, and J.A. Pask, Mullite and Mullite Ceramics, Adv. Mater. Opt. Electron., 1995, 5(5), p 284.

H. Schneider, J. Schreuer, and B. Hildmann, Structure and Properties of Mullite-A Review, J. Eur. Ceram. Soc., 2008, 28(2), p 329–344.

S. Pani, R.K. Sahoo, N. Dash, S.K. Singh, and B.K. Mohapatra, Cost Effective and Minimal Time Synthesis of Mullite from a Mine Waste by Thermal Plasma Process, Adv. Mater. Lett., 2015, 6(4), p 318–323.

V. Viswabaskaran, F.D. Gnanam, and M. Balasubramanian, Mullitisation Behaviour of South Indian Clays, Ceram. Int., 2002, 28(5), p 557–564.

J. Aguilar-Santillan, H. Balmori-Ramirez, and R.C. Bradt, Dense Mullite from Attrition Milled Kyanite and α-Alumina, J. Ceram. Process. Res., 2007, 8(1), p 1–11.

L. Zhou, Z. Li, and Y. Zhu, Porous Silica/Mullite Ceramics Prepared by Foam-Gelcasting Using Silicon Kerf Waste as Raw Material, Mater. Lett., 2019, 239, p 67–70.

R. Liu and D. **ang, Recycling Photovoltaic Silicon Waste for Fabricating Porous Mullite Ceramics by Low-Temperature Reaction Sintering, J. Eur. Ceram. Soc., 2021, 41(12), p 5957–5966.

A.N. Chen, J.Y. Chen, J.M. Wu, L.J. Cheng, R.Z. Liu, J. Liu, Y. Chen, C.H. Li, S.F. Wen, and Y.S. Shi, Porous Mullite Ceramics with Enhanced Mechanical Properties Prepared by SLS Using MnO2 and Phenolic Resin Coated Double-Shell Powders, Ceram. Int., 2019, 45(17), p 21136–21143.

C.O. Hulse and R.B. Graf, Effect of Temperature on the Mechanical Properties of Solid Pressure-Transmitting Media. II. Pyrophyllite, J. Appl. Phys., 1965, 36(5), p 1593–1596.

T.K. Mukhopadhyay, S. Ghatak, and H.S. Maiti, Effect of Pyrophyllite on the Mullitization in Triaxial Porcelain System, Ceram. Int., 2009, 35(4), p 1493–1500.

K.C. Rieger, Pyrophyllite, Am. Ceram. Soc. Bull., 1992, 71(5), p 500.

R. Sule and I. Sigalas, Influence of Excess Alumina on Mullite Synthesized from Pyrophyllite by Spark Plasma Sintering, Clay Miner., 2020, 55(2), p 166–171.

F. Wang, J. Ye, G. He, G. Liu, Z. **e, and J. Li, Preparation and Characterization of Porous MgAl2O4 Spinel Ceramic Supports from Bauxite and Magnesite, Ceram. Int., 2015, 41(6), p 7374–7380.

Z. Sun, J. Fan, and F. Yuan, Three-Dimensional Porous Silica Ceramics with Tailored Uniform Pores: Prepared by Inactive Spheres, J. Eur. Ceram. Soc., 2015, 35(13), p 3559–3566.

S. Hashimoto, S. Honda, T. Hiramatsu, and Y. Iwamoto, Fabrication of Porous Spinel (MgAl2O4) from Porous Alumina Using a Template Method, Ceram. Int., 2013, 39(2), p 2077–2081.

Z. Hou, H. Du, J. Liu, R. Hao, X. Dong, and M. Liu, Fabrication and Properties of Mullite Fiber Matrix Porous Ceramics by a TBA-Based Gel-Casting Process, J. Eur. Ceram. Soc., 2013, 33(4), p 717–725.

R. Liu, J. Yuan, and W. Changan, A Novel Way to Fabricate Tubular Porous Mullite Membrane Supports by TBA-Based Freezing Casting Method, J. Eur. Ceram. Soc., 2013, 33(15–16), p 3249–3256.

H. Guo, W. Li, and F. Ye, Low-Cost Porous Mullite Ceramic Membrane Supports Fabricated from Kyanite by Casting and Reaction Sintering, Ceram. Int., 2016, 42(4), p 4819–4826.

A. Standard, C1424-15” Standard Test Method for Monotonic Compressive Strength of Advanced Ceramics at Ambient Temperature, ASTM Int. West Conshohocken, PA, USA, 2015.

Y. Man, X. Luo, Z. **e, D. Qu, and S. **, Influence of 3D Printed Topological Structure on Lightweight Mullite Load Bearing Board in Thermal Environment, Adv. Mater. Sci. Eng., 2020, 2020, p 1–8.

J.A. Pask, Importance of Starting Materials on Reactions and Phase Equilibria in the Al2O3-SiO2 System, J. Eur. Ceram. Soc., 1996, 16(2), p 101–108.

D. Pereira, G.R.S. Biasibetti, R.V. Camerini, and A.S. Pereira, Sintering of Mullite by Different Methods, Mater. Manuf. Process., 2014, 29(4), p 391–396.

K.C. Liu, G. Thomas, A. Caballero, J.S. Moya, and S. Deaza, Mullite Formation in Kaolinite-Alpha-Alumina, Acta Metall. Mater., 1994, 42(2), p 489–495.

D. Pereira, G.R.S. Biasibetti, R.V. Camerini, and A.S. Pereira, Sintering of Mullite by Different Methods, Mater. Manuf. Process., 2014, 29, p 391–396.

H.S. Tripathi, A. Ghosh, M.K. Halder, B. Mukherjee, and H.S. Maiti, Microstructure and Properties of Sintered Mullite Developed from Indian Bauxite, Bull. Mater. Sci., 2012, 35(4), p 639–643.

R.L. Coble and W.D. Kingery, Effect of Porosity on Physical Properties of Sintered Alumina, J. Am. Ceram. Soc., 1956, 39(11), p 377–385.

S. Meille and E.J. Garboczi, Linear Elastic Properties of 2D and 3D Models of Porous Materials Made from Elongated Objects, Model. Simul. Mater. Sci. Eng., 2001, 9(5), p 371–390.

B.L. Metcalfe, The Synthesis, Microstructure and Physical Properties of High Purity Mullite, Trans. J. Brit. Ceram. Soc., 1975, 74, p 193–201.

T. Huang, M.N. Rahaman, T. Mah, and T.A. Parthasarathay, Anisotropic Grain Growth and Microstructural Evolution of Dense Mullite above 1550 C, J. Am. Ceram. Soc., 2000, 83(1), p 204–210.

S. Aramaki and R. Roy, Revised Phase Diagram for the System Al2O3-SiO2, J. Am. Ceram. Soc., 1962, 45(5), p 229–242.

A. Aksaf and J.A. Pask, Stable and Metastable Equilibria in the System SiO2-Al2O3, J. Am. Ceram. Soc., 1975, 58(11–12), p 507–512.

H. Guo and W. Li, Effects of Al2O3 Crystal Types on Morphologies, Formation Mechanisms of Mullite and Properties of Porous Mullite Ceramics Based on Kyanite, J. Eur. Ceram. Soc., 2018, 38(2), p 679–686.

D. Goski, Reaction Sintering of Kyanite and Alumina to Form Mullite Composites, Canad. Metall. Quart., 1999, 38(2), p 119–126. https://doi.org/10.1016/S0008-4433(98)00041-X

D. Michel, L. Mazerolles, and R. Portier, Directional Solidification in the Alumina--Silica System Microstructures and Interfaces, Mullite mullite matrix Compos., 1987, p 435–447.

J. Ylä-Jääski and H.-U. Nissen, Investigation of Superstructures in Mullite by High Resolution Electron Microscopy and Electron Diffraction, Phys. Chem. Miner., 1983, 10(2), p 47–54.

B. Dong, Z. Min, L. Guan, X. Zheng, L. Wang, Q. Wang, C. Yin, Y. Wang, R. Zhang, F. Wang, H. Abadikhah, X. **n, Y. Zhang, and G. Wang, Porous Mullite-Bonded SiC Filters Prepared by Foaming-Sol-Gel-Tape Casting for High-Efficiency Hot Flue Gas Filtration, Separat. Purificat. Technol., 2022, 295, p 121338. https://doi.org/10.1016/j.seppur.2022.121338

J. Zheng and J.S. Reed, Particle and Granule Parameters Affecting Compaction Efficiency in Dry Pressing, J. Am. Ceram. Soc., 1988, 71(11), p C456–C458.

R. Taktak, S. Baklouti, and J. Bouaziz, Effect of Binders on Microstructural and Mechanical Properties of Sintered Alumina, Mater. Charact., 2011, 62(9), p 912–916. https://doi.org/10.1016/j.matchar.2011.06.011

R. Zhang, C. Ye, X. Hou, S. Li, and B. Wang, Microstructure and Properties of Lightweight Fibrous Porous Mullite Ceramics Prepared by Vacuum Squeeze Moulding Technique, Ceram. Int., 2016, 42(13), p 14843–14848. https://doi.org/10.1016/j.ceramint.2016.06.118

D. Wu, J. Zhou, and Y. Li, Unbiased Estimation of Weibull Parameters with the Linear Regression Method, J. Eur. Ceram. Soc., 2006, 26(7), p 1099–1105. https://doi.org/10.1016/j.jeurceramsoc.2005.01.044

R. Bermejo, P. Supancic, and R. Danzer, Influence of Measurement Uncertainties on the Determination of the Weibull Distribution, J. Eur. Ceram. Soc., 2012, 32(2), p 251–255.

Acknowledgments

The authors would like to thank the University of the Witwatersrand; the Microscopy and Microanalysis Unit (MMU) for XRD; Mr Nelwalani for SEM analysis and DST-NRF Centre of Excellence (CoE) in Strong Materials for funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ntholeng, N., Rokebrand, P., Mphasha, N.P. et al. Properties of Porous Mullite Filter Material Fabricated from Reaction Sintered Mullite Grains. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08462-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08462-8