Abstract

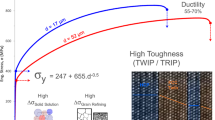

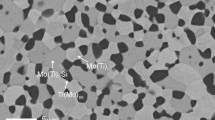

Two nominal Fe35Ni35Cr20Mn10 (in at.%) multi-principal-component alloys (MCAs) were prepared in vacuum-induction furnace with industrial purity (IP, > 98.5wt.%) and high-purity (HP, > 99.5wt.%) raw metals, respectively. The microstructure was characterized by XRD, SEM and TEM. Tensile mechanical properties and continual plastic deformation ability of them after hot-forging + homogenization annealing were examined by tensile test and continuous cold rolling test. For IP-MCA, the content of “impurity” elements (other elements excluding Fe, Ni, Cr and Mn) is high to 1.68wt.%. However, only single-FCC phase is detected by XRD and no any second phase particles are observed by SEM and TEM, just like that in HP-MCA with an impurity content of 0.4wt.%. It is interesting to find that IP-MCA possesses the equally excellent strength and elongation like HP-MCA. Cold rolling examination indicates that the sheet of IP-MCA with a thickness of 14.0 mm can be continuously rolled to a thin-strip of 0.35 mm. This exhibits an extremely excellent continuous plastic deformation ability, like HP-MAC. Thus, due to much lower cost, IP-MCA can be reliably step toward manufacturing industrial productions. Due to the tortile lattice in physic process for a give MCA system, the tolerability to impurity elements is thought to be large.

Similar content being viewed by others

Data Availability

No additional data are available.

References

B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent, Microstructural Development in Equiatomic Multicomponent Alloys, Mater. Sci. Eng. A, 2004, 375(10), p 213–218.

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang, Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes, Adv. Eng. Mater., 2004, 6(5), p 299–303.

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Ahmen, P.K. Liaw, and Z.P. Lu, Microstructures and Properties of High-Entropy Alloys, Prog. Mater. Sci., 2014, 61(10), p 1–93.

E.J. Pickering and N.G. Jones, High-Entropy Alloys: A Critical Assessment of Their Founding Principles and Future Prospects, Int. Mater. Rev., 2016, 61(3), p 183–202.

P. Edalati, R. Floriano, Y. Tang, A. Mohammadi, K.D. Pereira, A.D. Luchessi, and K. Edalati, Ultrahigh Hardness and Biocompatibility of High-Entropy Alloy TiAlFeCoNi Processed by High-Pressure Torsion, Mater. Sci. Eng. C, 2020, 112(11), p 110908.

J. Joseph, N. Haghdadi, M. Annasamy, S. Kada, P.D. Hodgson, M.R. Barnett, and D.M. Fabijanic, On the Enhanced Wear Resistance of CoCrFeMnNi High Entropy Alloy at Intermediate Temperature, Scr. Mater., 2020, 186(5), p 230–235.

F. Yang, L.M. Dong, L. Cai, X.J. Hu, and F. Fang, Mechanical Properties of FeMnCoCr High Entropy Alloy Alloyed with C/Si at Low Temperatures, J. Alloys Comp., 2021, 859, p 157876.

E.P. George, W.A. Curtin, and C.C. Tasan, High Entropy Alloys: A Focused Review of Mechanical Properties and Deformation Mechanisms, Acta Mater., 2020, 188(12), p 435–474.

Y. **e, T. **a, D. Zhou, Y.F. Luo, W. Zeng, Z. Zhang, J. Wang, J.M. Liang, and D.L. Zhang, A Novel Nanostructure to Achieve Ultrahigh Strength and Good Tensile Ductility of a CoCrFeNiMn High Entropy Alloy, Nanoscale, 2020, 12(9), p 5347–5352.

N.D. Stepanov, D.G. Shaysultanov, N.Y. Yurchenko, S.V. Zherebtsov, A.N. Ladygin, G.A. Salishchev, and M.A. Tikhonovsky, High Temperature Deformation Behavior and Dynamic Recrystallization in CoCrFeNiMn High Entropy Alloy, Mater. Sci. Eng. A, 2015, 636, p 188–195.

P. Wang, P. Huang, F.L. Ng, W.J. Sin, S.L. Lu, M.L. Nai, Z.L. Dong, and J. Wei, Additively Manufactured CoCrFeNiMn High-Entropy Alloy Via Pre-Alloyed Powder, Mater. Des., 2019, 168, p 107576.

F. Průša, A. Šenková, V. Kučera, J. Capek, and D. Vojtech, Properties of a High-Strength Ultrafine-Grained CoCrFeNiMn High-Entropy Alloy Prepared by Short-Term Mechanical Alloying and Spark Plasma Sintering, Mater. Sci. Eng. A, 2018, 734(8), p 341–352.

J.G. Gigax, O. El-Atwani, Q. McCulloch, B. Aytuna, M. Efe, S. Fensin, S.A. Maloy, and N. Li, Micro- and Mesoscale Mechanical Properties of a FeCrMnNi High Entropy Alloy Subject to Large Strain Extrusion Machining, Scri. Mater., 2020, 178(11), p 508–512.

W.Y. Huo, H. Zhou, F. Fang, X.J. Hu, Z.H. **e, and J.Q. Jiang, Strain-Rate Effect Upon the Tensile Behavior of CoCrFeNi High-Entropy Alloys, Mater. Sci. Eng. A, 2017, 689(2), p 366–369.

J. Zhou, H.C. Liao, H. Chen, and A.J. Huang, Microstructure and Tensile Mechanical Behavior of a Single-Phase Fe35Mn10Cr20Ni35 High-Entropy Alloy, J. Mater. Eng. Perf., 2021, 30(5), p 3352–3362.

Jun Zhou, T. Jiang, H. Liao, H. Chen, Y. Zhang, and W. Zhu, A Comparative Study on Corrosion Behaviors of Fe35Mn10Cr20Ni35 High‐Entropy Alloy and 304 Stainless Steel in Sulfuric Acid Aqueous Solution, Adv. Eng. Mater., 2022, 24(10), p 2200232. https://doi.org/10.1002/adem.202200232

H.C. Liao, H.T. Xu, J.F. Tang, S.H. Huo, D.Q. Huang, and H. Chen, Significant Strengthening Effect on Martensitic Stainless Steel by Repetitive High-Stress Loading at Ultralow Temperature, Metall. Mater. Trans. A, 2020, 51, p 76–81.

A. Portevin and F. Le Chatelier, Tensile Tests of Alloys Undergoing Transformation, Comptes. Rendus Acad. Sci. (CRAS), 1923, 176, p 507–510.

P. Fernandez-Zelaia, B.S. Adair, V.M. Barker, and S.D. Antolovich, The Portevin-Le Chatelier Effect in the Ni-Based Superalloy IN100, Metall. Mater. Trans. A, 2015, 46(12), p 5596–5609.

S.C. Ren, T.F. Morgeneyer, M. Maziere, S. Forest, and G. Rousselier, Portevin-Le Chatelier Effect Triggered by Complex Loading Paths in an Al-Cu Aluminium Alloy, Philos. Mag., 2019, 99, p 659–678.

T. Li, Y. Liu, Z. Cao, D. Jiang, and L. Cheng, The Tensile Properties and High Cyclic Fatigue Characteristics of Mg-5Li-3Al-1.5Zn-2RE Alloy, Mater. Sci. Eng. A, 2010, 527(29–30), p 7808–7811. https://doi.org/10.1016/j.msea.2010.08.094

X. Yang, Y. Zhang, and P.K. Liaw, Microstructure and Compressive Properties of NbTiVTaAlx High Entropy Alloys, Procedia Eng., 2012, 36(3), p 292–298.

H.F. Sheng, M. Gong, and L.M. Peng, Microstructural Characterization and Mechanical Properties of an Al0.5CoCrFeCuNi High-Entropy Alloy in As-Cast and Heat-Treated/Quenched Conditions, Mater. Sci. Eng. A, 2013, 567(5), p 14–20.

F. Zhiqiang, W. Chen, H. Wen, D. Zhang, Z. Chen, B. Zheng, Y. Zhou, and E.J. Lavernia, Microstructure and Strengthening Mechanisms in an FCC Structured Single-Phase Nanocrystalline Co25Ni25Fe25Al7.5Cu17.5 High-Entropy Alloy, Acta Mater., 2016, 107, p 59–71. https://doi.org/10.1016/j.actamat.2016.01.050

A. Emamifar, B. Sadeghi, P. Cavaliere, and H. Ziaei, Microstructural Evolution and Mechanical Properties of AlCrFeNiCoC High Entropy Alloy Produced Via Spark Plasma Sintering, Powder Metall., 2019, 62(1), p 61–70.

J.Y. He, W.H. Liu, H. Wang, Y. Wu, X.J. Liu, T.G. Nieh, and Z.P. Lu, Effects of Al Addition on Structural Evolution and Tensile Properties of the FeCoNiCrMn High-Entropy Alloy System, Acta Mater., 2014, 62, p 105–113.

A. Griger, V. Stefaniay, T. Turmezey, and Z. Metallkd, Crystallographic Data and Chemical Compositions of Aluminum-Rich Al-Fe Intermetallic Phases, Zeitschrift fuer Metallkunde/Mater. Res. Adv. Techn., 1986, 77, p 30–35.

L. Guo, X.Q. Ou, S. Ni, Y. Liu, and M. Song, Effects of Carbon on the Microstructures and Mechanical Properties of FeCoCrNiMn High Entropy Alloys, Mate. Sci. Eng. A, 2019, 746, p 356–362.

M. Hasebe, H. Ohtani, and T. Nishizawa, Effect of Magnetic Transition on Solubility of Carbon in bcc Fe and FCC Co-Ni Alloys, Metall. Trans., 1985, 16(5), p 913–921.

W.H. Liu, Z.P. Lu, J.Y. He, J.H. Luan, Z.J. Wang, B. Liu, Y. Liu, M.W. Chen, and C.T. Liu, Ductile CoCrFeNiMox High Entropy Alloys Strengthened by Hard Intermetallic Phases, Acta Mater., 2016, 116(6), p 332–342.

Y. Liu, Y.X. **e, S.G. Cui, Y.L. Yi, X.W. **ng, X.J. Wang, and W. Li, Effect of Mo Element on the Mechanical Properties and Tribological Responses of CoCrFeNiMox High-Entropy Alloys, Metals, 2021, 11(03), p 486.

T. Shun, L. Chang, and M.H. Shiu, Microstructures and Mechanical Properties of Multi-Principal Component CoCrFeNiTix Alloys, Mate. Sci. Eng. A, 2012, 556(6), p 170–174.

H. Liu, C. Tsai, and C. Wei, Effect of Ge Addition on the Microstructure, Mechanical Properties, and Corrosion Behavior of CoCrFeNi High-Entropy Alloys, Intermetallics, 2021, 132, p 107167.

A. Takeuchi and A. Inoue, Classification of Bulk Metallic Glasses by Atomic Size Difference, Heat of Mixing and Period of Constituent Elements and Its Application to Characterization of the Main Alloying Element, Mater. Trans., 2005, 46(12), p 2817–2829.

T. Iida and R.I.L. Guthrie, The Physical Properties of Liquid Metals, 2nd ed. Oxford University Press, New York, 1993.

G.C. Kennedy, AIP Handbook. D.E. Gray Ed., McGrawHill, New York, 1972

A.R. Stokes and A.J.C. Wilson, The Diffraction of X rays by Distorted Crystal Aggregates-I, Proc. Phys. Soc., 1944, 56(3), p 174.

L.B. McCusker, R.B. Von Dreele, D.E. Cox, D. Louer, and P. Scardi, Rietveld Refinement Guidelines, J. Appl. Cryst., 1999, 32, p 36–50.

G.K. Williamson and W.H. Hall, X-ray Line Broadening from Filed Aluminium and Wolfram, Acta Metall., 1953, 1(1), p 22–31.

Z. Wang, Y. Huang, Y. Yang, J. Wang, and C.T. Liu, Atomic-Size Effect and Solid Solubility of Multicomponent Alloys, Scr. Mater., 2014, 94(9), p 28–31.

R.L. Fleischer, Substitutional Solution Hardening, Acta Metall., 1963, 11(3), p 203–209.

Acknowledgments

This work was funded by National Major Basic Research Project of China (Grant No.: 613321), Open Project of Jiangsu Key Laboratory (Grant No.: BM2016023) and Transformation Project of Scientific and Technological Achievements in Jiangsu Province (Grant No.: BA2020023).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interest or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liao, H., Zhang, Y., Wu, D. et al. Tolerability of Fe35Ni35Cr20Mn10 Multi-principal-component Alloy to Impurity Elements. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08351-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08351-0