Abstract

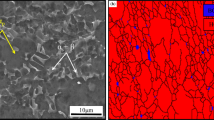

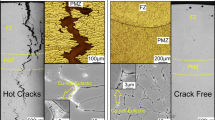

To tackle the critical challenge concerning the disparate performance outcomes between the spoke and rim in extruded AZ80 magnesium alloy wheel hub, finite element simulation was used to optimize the shape parameters of the hollow billet and improved equivalent strain was achieved. The paper studied the microstructure evolution and mechanical property response of the alloy after the forming process. The experimental results showed that the grain sizes of the spoke and rim were 32.95 and 33.84 μm, respectively, when using the optimized shape parameters, and both of them were completely dynamically recrystallized. Although the fine grain strengthening and precipitation hardening effects were consistently obtained in both samples, a discernible distinction was revealed by the mechanical property analysis. Specifically, the yield strength (YS) and ultimate tensile strength (UTS) of the rim specimens evinced a notable 13.8 and 15.4% higher in comparison to the spoke specimens. This discrepancy was further elucidated by the texture analysis, which illuminated that the spoke was distinguished by an extrusion direction–transverse direction double-peak basal texture, while the rim was marked by a normal direction–transverse direction (ND–TD) double-peak basal component after extrusion. The distinct texture patterns gave rise to varying predominant deformation mechanisms during loaded at room temperature, where the textured TD-oriented grains within the spoke unfriendly promoted the initiation of {10-12} tensile twinning at low yield stress, while both the ND and TD component within the hub manifested a markedly high activation of prismatic slip with high yield stress. The cumulative effect of these contrasting deformation pathways ultimately led to a marked contrast in the YS between the two regions.

Similar content being viewed by others

References

Q. Wang, Z.-M. Zhang, X. Zhang, and Yu. Jian-min, Precision Forging Technologies for Magnesium Alloy Bracket and Wheel, Trans. Nonferrous Met. Soc. China, 2008, 18, p 205–208.

Q. Wang, Z.-M. Zhang, X. Zhang, and G.-J. Li, New Extrusion Process of Mg Alloy Automobile Wheels, Trans. Nonferrous Met. Soc. China, 2010, 20, p 599–603.

G. Rivers, Cyclic Fatigue Behaviour of Wrought AZ80 Magnesium Alloy from Forged Automotive Wheel. M.Sc. thesis, McMaster University, 2011.

P. Li, D.M. Maijer, T.C. Lindley, and P.D. Lee, A through Process Model of the Impact of In-Service Loading, Residual Stress, and Microstructure on the Final Fatigue Life of an A356 Automotive Wheel, Mater. Sci. Eng. A, 2007, 460, p 20–30.

R. Shang, W. Altenhof, H. Hu, and N. Li, Rotary Fatigue Analysis of Forged Magnesium Road Wheels, SAE Int. J. Mater. Manf., 2008, 1(1), p 9–15.

W. Song, J.L. Woods, R.T. Davis, J.K. Offutt, E.P. Bellis, E.S. Handler, C.K. Sullivan, and T.W. Stone, Failure Analysis and Simulation Evaluation of an Al 6061 Alloy Wheel Hub, J Fail. Anal. Preven., 2015, 15(4), p 521–533.

E.K. Orhorhoro, I.A. Essienubong, and O.O. Joel, Failure Analysis and Optimization of Aircraft Wheel Hub for Optimum Landing Scenario, IJETT, 2018, 60(2), p 135–141.

J. Wu, Research on Microstructure and Properties of Az80 Alloy Forged Wheel Hub, AMC, 2014, 02(02), p 13–20.

L.Y. Geng, Q. Wang, Y.B. Yang, Z.M. Zhang, M.J. Liang, and Y. Ren, 基于空心坯料挤压AZ80镁合金轮毂组织与性能研究 (microstructure and mechanical properties of AZ80 magnesium alloy wheel hubs produced by extrusion process using hollow billet), Ordnance Mater. Sci. Eng, 2018, 41(2), p 11–15. (in Chinese)

Y. Ren, Q. Wang, Z.M. Zhang, and J. Wang, 空心坯料挤压和传统挤压AZ80镁合金轮毂工艺对比研究 (microstructure and mechanical properties of AZ80 magnesium alloy wheel hubs produced by extrusion process using hollow billet), Light Alloy Fabr. Technol, 2018, 46(11), p 50–54+60. (in Chinese)

X. Zhao, P. Gao, Z. Zhang, Q. Wang, and F. Yan, Fatigue Characteristics of the Extruded AZ80 Automotive Wheel, Int J Fatigue, 2020, 132, p 105393.

W. Wang, G. Cui, W. Zhang, W. Chen, and E. Wang, Evolution of Microstructure, Texture and Mechanical Properties of ZK60 Magnesium Alloy in a Single Rolling Pass, Mater. Sci. Eng. A, 2018, 724, p 486–492.

A. Imandoust, C.D. Barrett, A.L. Oppedal, W.R. Whittington, Y. Paudel, and H. El Kadiri, Nucleation and Preferential Growth Mechanism of Recrystallization Texture in High Purity Binary Magnesium-Rare Earth Alloys, Acta Mater., 2017, 138, p 27–41.

X.X. Zhong, M. Fang, H.T. Yu, and W.G. Li, AZ80+Ce镁合金轮毂成形过程中的组织演变 (Microstructure Evolution of AZ80+Ce Magnesium Alloy Wheel Hub During Forming), Hot Work. Technol., 2016, 45(7), p 141–143. (in Chinese)

J. wang, X. Che, Y.B. Yang, Z.M. Zhang, L.Y. Geng, and Q. Wang, 扩收挤压成形的AZ80镁合金轮毂高周疲劳性能 (High Cycle Fatigue Properties of AZ80 Magnesium Alloy Wheels Hub Formed by Expansion-Reduced Extrusion), Hot Work. Technol., 2022, 51(3), p 17–21+25. (in Chinese)

Q. Wang, M. Meng, Q.L. Fang, and Z.M. Zhang, 复合挤压在铝合金轮毂成形中的应用研究 (Application of compound extrusion in aluminum alloy wheel hub forming), J. Plast. Eng., 2020, 27(12), p 18–23. (in Chinese)

Y. Wang, M. **a, Z. Fan, X. Zhou, and G.E. Thompson, The Effect of Al8Mn5 Intermetallic Particles on Grain Size of As-Cast Mg–Al–Zn AZ91D Alloy, Intermetallics (Barking), 2010, 18(8), p 1683–1689.

S.-C. **, J.W. Cha, J. Go, J.H. Bae, and S.H. Park, Comparative Study of Extrudability, Microstructure, and Mechanical Properties of AZ80 and BA53 Alloys, J. Magnes. Alloy, 2021 https://doi.org/10.1016/j.jma.2021.07.009

Z. Wang, J.-G. Wang, Z.-Y. Chen, M. Zha, C. Wang, S. Liu, and R.-F. Yan, Effect of Ce Addition on Modifying the Microstructure and Achieving a High Elongation with a Relatively High Strength of As-Extruded AZ80 Magnesium Alloy, Materials, 2018, 12(1), p 76.

Xu. Wang Wei, Z.J. Chunxiang, C. Weili, and N. **aofeng, Effects of Ce Addition on Microstructure, Mechanical Properties and Corrosion Resistance of as-cast AZ80 Magnesium Alloy, China Foundry, 2014, 11(03), p 157–162.

M.G. Jiang, C. Xu, H. Yan, G.H. Fan, T. Nakata, C.S. Lao, R.S. Chen, S. Kamado, E.H. Han, and B.H. Lu, Unveiling the Formation of Basal Texture Variations Based on Twinning and Dynamic Recrystallization in AZ31 Magnesium Alloy during Extrusion, Acta Mater., 2018, 157, p 53–71.

S.-H. Kim, S.W. Lee, B.G. Moon, H.S. Kim, Y.M. Kim, and S.H. Park, Influence of Extrusion Temperature on Dynamic Deformation Behaviors and Mechanical Properties of Mg-8Al-0.5Zn-0.2Mn-0.3Ca-02Y Alloy, J. Mater. Res. Technol., 2019, 8(6), p 5254–5270.

P. Prakash, D. Toscano, S.K. Shaha, M.A. Wells, H. Jahed, and B.W. Williams, Effect of Temperature on the Hot Deformation Behavior of AZ80 Magnesium Alloy, Mater. Sci. Eng. A, 2020, 794, p 139923.

L. Jiang, W. Huang, D. Zhang, F. Guo, H. Xue, J. Xu, and F. Pan, Effect of Sn on the Microstructure Evolution of AZ80 Magnesium Alloy during Hot Compression, J. Alloys Compd., 2017, 727, p 205–214.

A. Zindal, J. Jain, R. Prasad, S.S. Singh, R. Sarvesha, P. Cizek, and M.R. Barnett, Effect of Heat Treatment Variables on the Formation of Precipitate Free Zones (PFZs) in Mg-8Al-0.5Zn Alloy, Mater Charact, 2018, 136, p 175–182.

X. Zhao, F.-F. Yan, Z.-M. Zhang, P.-C. Gao, and S.-C. Li, Influence of Heat Treatment on Precipitation Behavior and Mechanical Properties of Extruded AZ80 Magnesium Alloy, Acta Metall. Sin. (Engl. Lett.), 2021, 34(1), p 54–64.

S. **, H. Liu, R. Wu, F. Zhong, L. Hou, and J. Zhang, Combination Effects of Yb Addition and Cryogenic-Rolling on Microstructure and Mechanical Properties of LA141 Alloy, Mater. Sci. Eng. A, 2020, 788, p 139611.

Z. Wang, X. Zhao, Z. Zhang, Y. Wu, K. Chen, X. Ren, D. Wang, and W. Wang, Strengthening Effect of Prefabrication (10–12) Tensile Twinning on AZ80+0.4%Ce Magnesium Alloy and Inhibition Mechanism of Discontinuous Precipitation, J. Magnes. Alloy, 2022 https://doi.org/10.1016/j.jma.2022.09.013

Q. Yang, B. Jiang, Y. Tian, W. Liu, and F. Pan, A Tilted Weak Texture Processed by an Asymmetric Extrusion for Magnesium Alloy Sheets, Mater. Lett., 2013, 100, p 29–31.

Q. Wang, B. Jiang, A. Tang, S. Ma, Z. Jiang, Y. Chai, B. Liu, and F. Pan, Ameliorating the Mechanical Properties of Magnesium Alloy: Role of Texture, Mater. Sci. Eng. A, 2017, 689, p 395–403.

Q. Wang, J. Song, B. Jiang, A. Tang, Y. Chai, T. Yang, G. Huang, and F. Pan, An Investigation on Microstructure, Texture and Formability of AZ31 Sheet Processed by Asymmetric Porthole Die Extrusion, Mater. Sci. Eng. A, 2018, 720, p 85–97.

S.W. Xu, S. Kamado, and T. Honma, Effect of Homogenization on Microstructures and Mechanical Properties of Hot Compressed Mg–9Al–1Zn Alloy, Mater. Sci. Eng. A, 2011, 528(6), p 2385–2393.

A. Zindal, J. Jain, R. Prasad, S.S. Singh, and P. Cizek, Correlation of Grain Boundary Precipitate Characteristics with Fracture and Fracture Toughness in an Mg-8Al-0.5 Zn Alloy, Mater. Sci. Eng. A, 2017, 706, p 192–200.

**. Zhao, S. Li, Y. Zheng, Z. Liu, K. Chen, Yu. JianMin, Z. Zhang, and S. Zheng, The Microstructure Evolution, Texture Weakening Mechanism and Mechanical Properties of AZ80 Mg Alloy Processed by Repetitive Upsetting-Extrusion with Reduced Deformation Temperature, J. Alloys Compd., 2021, 883, p 160871.

Z. **, Li. Shuchang, Z. Zhimin, G. Pengcheng, K. Shuailing, and Y. Fafa, Comparisons of Microstructure Homogeneity, Texture and Mechanical Properties of AZ80 Magnesium Alloy Fabricated by Annular Channel Angular Extrusion and Backward Extrusion, J. Magnes. Alloy, 2020, 8(3), p 624–639.

W.B. Hutchinson and M.R. Barnett, Effective Values of Critical Resolved Shear Stress for Slip in Polycrystalline Magnesium and Other Hcp Metals, Scr. Mater., 2010, 63(7), p 737–740.

A. Poty, J.-M. Raulot, H. Xu, J. Bai, C. Schuman, J.-S. Lecomte, M.-J. Philippe, and C. Esling, Classification of the Critical Resolved Shear Stress in the Hexagonal-Close-Packed Materials by Atomic Simulation: Application to α-Zirconium and α-Titanium, J. Appl. Phys., 2011, 110(1), p 014905.

X. Lou, M. Li, R. Boger, S. Agnew, and R. Wagoner, Hardening Evolution of AZ31B Mg Sheet, Int. J. Plast., 2007, 23(1), p 44–86.

Acknowledgments

The authors gratefully acknowledge the financial supports from Program for the Supported by Youth Innovation Team in Shanxi Province; the ‘Shanxi Province’s key core technology and common technology research and development special project’ (2020XXX015); and Ningbo Natural Science Foundation (Project 2021J231; 2021J232)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cheng, Y., Li, S., He, Y. et al. Performance Difference Between the Spoke and Rim in an Extruded AZ80 + 0.4%Ce Magnesium Alloy Wheel under Equal Strain. J. of Materi Eng and Perform 33, 4659–4670 (2024). https://doi.org/10.1007/s11665-023-08269-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-08269-7