Abstract

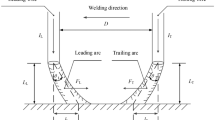

An integrated aluminum alloy double-wire pulsed current gas metal arc welding system with a median waveform is developed. A digital oscilloscope acquires the voltage and current waveforms of the front median pulse (FMP) and back median pulse (BMP). At the same time, a high-speed camera records the metal transfer processes of FMP and BMP. The metal transfer behavior is analyzed. The experimental results showed that FMP and BMP could obtain stable voltage and current waveforms in addition to achieving continuous welds. In the case of the FMP, the metal transfer mode is one drop multi-pulse, precisely one drop two-pulse mode. The droplet diameter is large, so droplet collisions are more likely to occur, causing the welding process to splash around severely. In the case of the BMP, one drop per pulse (ODPP), the ideal mode, is achieved. The droplet diameter is small, so the spatter is limited, and the welding process appears more stable than that of FMP. The BMP can promote metal transfer, making it easier to achieve ODPP using the same parameters. In addition, the weld quality of BMP is better than that of FMP, in which the fish-scale ripples are prominent.

Similar content being viewed by others

References

K. Michie, S. Blackman, and T.E.B. Ogunbiyi, Twin Wire GMAW: Process Characteristics and Applications, Weld. J., 1999, 78(5), p 31s–34s.

T. Matsumoto and S. Sasabe, Tandem MIG Welding of Aluminium Alloys, Weld. Int., 2005, 19(12), p 945–949.

P.K. Ghosh, L. Dorn, S. Kulkarni, and F. Hofmann, Arc Characteristics and Behaviour of Metal Transfer in Pulsed Current GMA Welding of Stainless Steel, J. Mater. Process. Tech., 2009, 209, p 1262–1274.

V.L. Jorge, F.M. Scotti, R.P. Reis, and A. Scotti, Wire Feed Pulsation as a Means of Inducing Surface Tension Metal Transfer in Gas Metal Arc Welding, J. Manuf. Process., 2021, 62, p 655–669.

X.P. Ding, H. Li, H.L. Wei, and J.Q. Liu, Numerical Analysis of Arc Plasma Behavior in Double-Wire GMAW, Vacuum, 2016, 124, p 46–54.

X.C. Zhang, H.M. Gao, and G.J. Zhang, Current-Independent Metal Transfer by Utilizing Droplet Resonance in Gas Metal Arc Welding, J. Mater. Process. Tech., 2020, 279, p 116571.

A. Scotti, C.O. Morais, and L.O. Vilarinho, The Effect of Out-of-Phase Pulsing on Metal Transfer in Twin-Wire GMA Welding at High Current Level, Weld. J., 2006, 85(10), p 225s–230s.

P.J. Groetelaars, C.O. Morais, and A. Scotti, Influence of the Arc Length on Metal Transfer in the Single Potential Double-Wire MIG/MAG Process, Weld. Int., 2009, 23(2), p 112–119.

H.L. Wei, H. Li, Y. Gao, X.P. Ding, and L.J. Yang, Welding Process of Consumable Double Electrode with a Single Arc GMAW, Int. J. Adv. Manuf. Technol., 2015, 76(1–4), p 435–446.

T. **ang, H. Li, H.L. Wei, and Y. Gao, Arc Characteristics and Metal Transfer Behavior of Twin-Arc Integrated Cold Wire Hybrid Welding, Int. J. Adv. Manuf. Technol., 2016, 87(9–12), p 2653–2663.

T. **ang, H. Li, C.Q. Huang, H.L. Wei, J.X. Li, and Y. Gao, The Metal Transfer Behavior and the Effect of Arcing Mode on Metal Transfer Process in Twin-Arc Integrated Cold Wire Hybrid Welding, Int. J. Adv. Manuf. Technol., 2017, 90(1–4), p 1043–1050.

P.J. Groetelaars, C.O. de Morais, and A. Scotti, Influence of the Arc Length on Metal Transfer in the Single Potential Double-Wire MIG/MAG Process, Weld. J., 2009, 23(2), p 112–119.

K.Y. Wu, T. Yin, N. Ding, M. Zeng, and Z.Y. Liang, Effect of Phase on the Behavior of Metal Transfer in Double-Wire Pulsed GMAW, Int. J. Adv. Manuf. Technol., 2018, 97(9–12), p 3777–3789.

K.Y. Wu, X.W. Cao, T. Yin, M. Zeng, and Z.Y. Liang, Metal Transfer Process and Properties of Double-Wire Double Pulsed Gas Metal Arc Welding, J. Manuf. Process., 2019, 44, p 367–375.

Md.R.U. Ahsan, Y.R. Kim, C.H. Kim, J.W. Kim, R. Ashiri, and Y.D. Park, Porosity Formation Mechanisms in Cold Metal Transfer (CMT) Gas Metal Arc Welding (GMAW) of Zinc Coated Steels, Sci. Technol. Weld. Joining., 2016, 21(3), p 209–215.

Md.R.U. Ahsan, Y.R. Kim, R. Ashiri, Y.J. Cho, C. Jeong, and Y.D. Park, Cold Metal Transfer (CMT) GMAW of Zinc-Coated Steel, Weld. J., 2016, 95(4), p 120s–132s.

Md.R.U. Ahsan, M. Cheeepu, R. Ashiri, T.H. Kim, C. Jeong, and Y.D. Park, Mechanisms of Weld Pool Flow and Slag Formation Location in Cold Metal Transfer (CMT) Gas Metal Arc Welding (GMAW), Weld. World., 2017, 61(6), p 1275–1285.

H. Zheng, B.J. Qi, and M.X. Yang, Dynamic Analysis of the Ultrasonic-Frequency Pulsed GMAW Metal Transfer Process, J. Manuf. Process., 2021, 62, p 283–290.

D.S. Chen, M.A. Chen, and C.S. Wu, Effects of Phase Difference on the Behavior of Arc and Weld Pool in Tandem P-GMAW, J. Mater. Process. Tech., 2015, 225, p 45–55.

P. Yao, J.X. Xue, K. Zhou, X.J. Wang, and Q. Zhu, Symmetrical Transition Waveform Control on Double-Wire MIG Welding, J. Mater. Process. Tech., 2016, 229, p 111–120.

P. Yao and K. Zhou, Research of a Multi-Frequency Waveform Control Method on Double-Wire MIG Arc Welding, Appl. Sci., 2017, 7(2), p 1–16.

H. Chen, J.X. Xue, and G.C. Heng, Improvement of Double Wire MIG Welding by Using Sine Wave Pulse Modulation Control Method (Hangzhou, China), IEEE Int. Conf. Intell. Human-Mach. Syst. Cybern., 2017, 1, p 451–455.

S.Q. Moinuddin and A. Sharma, Arc Stability and Its Impact on Weld Properties and Microstructure in Anti-Phase Synchronised Synergic-Pulsed Twin-Wire Gas Metal Arc Welding, Mater. Des., 2015, 67, p 293–302.

Z.D. Zhang and X.Y. Kong, Study on DC Double Pulse Metal Inert Gas (MIG) Welding of Magnesium Alloy, Mater. Manuf. Process., 2012, 27(4), p 462–466.

L.L. Wang, L. **, W.J. Huang, and J.X. Xue, Effect of Thermal Frequency on AA6061 Aluminum Alloy Double Pulsed Gas Metal Arc Welding, Mater. Manuf. Process., 2016, 31(16), p 2152–2157.

L.L. Wang, H.L. Wei, J.X. Xue, and T. DebRoy, A Pathway to Microstructural Refinement through Double Pulsed Gas Metal Arc Welding, Scripta Mater., 2017, 134, p 61–65.

K.Y. Wu, Z.Y. Liang, T. Yin, Z.W. He, and M. Zeng, Double Pulse Low-Frequency Modulation for High-Power Double-Wire Pulsed GMAW, ASME J. Manuf. Sci. Eng., 2018, 140(9), p 091004.

K.Y. Wu, N. Ding, T. Yin, M. Zeng, and Z.Y. Liang, Effects of Single and Double Pulses on Microstructure and Mechanical Properties of Weld Joints During High-Power Double-Wire GMAW, J. Manuf. Process., 2018, 35, p 728–734.

K.Y. Wu, J.T. Zhan, X.W. Cao, M. Zeng, and N. Ding, Metal Transfer of Aluminum Alloy Double-Wire Pulsed GMAW with a Median Waveform, J. Mater. Process. Tech., 2020, 286, p 116761.

B. Mvola, P. Kah, and P. Layus, Review of Current Waveform Control Effects on Weld Geometry in Gas Metal Arc Welding Process, Int. J. Adv. Manuf. Technol., 2018, 96(9–12), p 4243–4265.

I. Pires, L. Quintino, and R.M. Miranda, Analysis of the Influence of Shielding Gas Mixtures on the Gas Metal Arc Welding Metal Transfer Modes and Fume Formation Rate, Mater. Des., 2007, 28(5), p 1623–1631.

T. Ueyama, T. Ohnawa, M. Tanaka, and K. Nakata, Occurrence of Arc Interaction in Tandem Pulsed Gas Metal Arc Welding, Sci. Technol. Weld. Joi., 2007, 12(6), p 523–529.

X.P. Ding, H. Li, L. Yang, and Y. Gao, Numerical Simulation of Metal Transfer Process in Tandem GMAW, Int. J. Adv. Manuf. Technol., 2013, 69(1–4), p 107–112.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wu, K., Tao, T., Wang, Y. et al. Metal Transfer Behavior in AA6061 Aluminum Alloy Double-Wire Median Pulsed Gas Metal Arc Welding. J. of Materi Eng and Perform 33, 2573–2584 (2024). https://doi.org/10.1007/s11665-023-08178-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-08178-9