Abstract

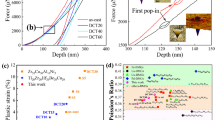

(Zr0.6336Cu0.1452Ni0.1012Al0.12)97.4Er2.6 bulk metallic glass (BMG) was prepared by copper mold suction casting, and the effects of sub-Tg annealing and cryogenic thermal cycle (CTC) treatment on its microstructure and properties were investigated. Although the specimens after annealing and CTC treatment did not have significant changes in the amorphous structure, the treated specimens exhibited excellent compressive plastic strain of 16.44 and 19.08%, representing an enhancement of 22.59 and 42.28% compared with the as-cast specimens. The change in plasticity was closely related to the arrangement of atoms and the content and distribution of the free volume caused by sub-Tg annealing and CTC treatment. The corrosion resistance of the specimen was further optimized after sub-Tg annealing and CTC treatment and gradually increased with the increase of annealing temperature and the CTC times. This work demonstrated that appropriate annealing temperature and CTC conditions could be used as an effective and controllable way to modulate the mechanical properties of BMGs.

Similar content being viewed by others

References

T. Burgess and M. Ferry, Nanoindentation of Metallic Glasses, Mater. Today, 2009, 12(1–2), p 24–32.

M.K. Miller, and P.K. Liaw, Bulk Metallic Glasses, Mat. Sci. Eng. R, 2004, 44(2–3), p 45–89.

C. Suryanarayana and A. Inoue, Bulk Metallic Glasses, Intermetallics, 2003, 11(6), p 529–540.

W.F. Zhang, Y. Meng, J.F. Wang, S.K. Guan, and T. Zhang, Effect of Continuous Rapid Annealing on the Microstructure and Properties of Fe85P11C2B2 Amorphous Alloy, Mater. Lett., 2022, 315, p 131984.

Y. Huang, W. Zheng, H. Fan, D. Wang, J. Shen, and J. Mi, The Effects of Annealing on the Microstructure and the Dynamic Mechanical Strength of a ZrCuNiAl Bulk Metallic Glass, Intermetallics, 2013, 42, p 192–197.

G. Zha and A. Zhang, Effects of Annealing Temperature on Microstructure and Hardness of (Cu60Zr30Ti10)98Y2 Bulk Metallic Glass, J. Rare Earths, 2010, 28(2), p 243–245. (In English)

A. Hitit, M. Geçgin, and P. Öztürk, Effect of Annealing on Microstructure and Microhardness of Co-Fe-Ni-Ta-B-Si Bulk Metallic Glass, J. Mater. Sci. Technol., 2015, 31(2), p 148–152.

S.X. Yang, Z.P. Liu, S.M. Han, W. Zhang, and J.Z. Song, Effects of Annealing Treatment on the Microstructure and Electrochemical Properties of Low-Co Hydrogen Storage Alloys Containing Cu and Fe, Rare Met., 2011, 30(5), p 464–469.

H.S. Chen, On mechanisms of Structural Relaxation in a Pd48Ni32P20 Glass, J. Non-Cryst. Solids, 1981, 46, p 289–305.

J.J. Lewandowski, W.H. Wang, and A.L. Greer, Intrinsic Plasticity or Brittleness of Metallic Glasses, Philos. Mag. Lett., 2005, 85, p 77–87.

J.J. Lewandowski, M. Shazly, and A.S. Nouri, Intrinsic and Extrinsic Toughening of Metallic Glasses, Scr. Mater., 2006, 54(3), p 37–41.

G. Kumar, D. Rector, R.D. Conner, and J. Schroers, Embrittlement of Zr-Based Bulk Metallic Glasses, Acta Mater., 2009, 57(35), p 72–83.

Z. Chen, A. Datye, J. Ketkaew, S. Sohn, C. Zhou, O.E. Dagdeviren, J. Schroers, and U.D. Schwarza, Relaxation and Crystallization Studied by Observing the Surface Morphology Evolution of Atomically Flat Pt57.5Cu14.7Ni5.3P22.5 upon Annealing, Scr. Mater., 2020, 182, p 32–37.

P.H. Tsai, S.K. Wang, S.R. Jian, I.S. Lee, Y.Z. Chang, Y.Z. Lin, J.S.C. Jang, and C. Li, Effect of Partial Crystallization on Mechanical Properties of (Cu42Zr42Al8Ag8)99.5Si0.5 Bulk Metallic Glass, Mater. Technol., 2012, 27(1), p 43–45.

F.X. Qin, X.M. Wang, and A. Inoue, Effect of Annealing on Microstructure and Mechanical Property of a Ti-Zr-Cu-Pd Bulk Metallic Glass, Intermetallics, 2007, 15(10), p 1337–1342.

H.J. Jun, K.S. Lee, C.P. Kim, and Y.W. Chang, Ductility Enhancement of a Ti-Based Bulk Metallic Glass through Annealing Treatment Below the Glass Transition Temperature, Intermetallics, 2012, 20, p 47–54.

D. Pan, Y. Yokoyama, T. Fujita, Y.H. Liu, S. Kohara, and A. Inoue, Correlation between Structural Relaxation and Shear Transformation Zone Volume of a Bulk Metallic Glass, Appl. Phys. Lett., 2009, 95, p 141909.

H. Shi, C. Tang, X. Zhao, Y. Ding, and X. Shen, Effect of Isothermal Annealing on Mechanical Performance and Corrosion Resistance of Ni-Free Zr59Ti6Cu17.5Fe10Al7.5 Bulk Metallic Glass, Non-Cryst. Solids, 2020, 537, p 120013.

H. Shi, Z. Li, Z. Hu, Y. Ding, and X. Shen, Enhancing Strength and Plasticity of Zr-Based Bulk Metallic Glasses by Zr Partially Substituted Fe and Isothermal Annealing, J. Non-Cryst. Solids, 2020, 543, p 120163.

W. Zhang, K. Li, Q. **ang, Y. Ren, Q. Li, and K. Qiu, The Rejuvenation and Relaxation around the Glass Transition of a Ce-Based Metallic Glass Controlled by Annealing, Quenching and Cryogenic Treatments, J. Non-Cryst. Solids, 2020, 548, p 120334.

M. Zhou, K. Hagos, H. Huang, M. Yang, and L. Ma, Improved Mechanical Properties and Pitting Corrosion Resistance of Zr65Cu17.5Fe10Al7.5 Bulk Metallic Glass by Isothermal Annealing, J. Non-Cryst. Solids, 2016, 452, p 50–56.

T. Wang, L. Zhang, Q. Hou, Q. Hao, and J. Qiao, Improvement the Plasticity of Fe-Based Bulk Metallic Glass via Low Temperature Annealing, J. Non-Cryst. Solids, 2021, 569, p 120965.

J. Saida, R. Yamada, M. Wakeda, and S. Ogata, Thermal Rejuvenation in Metallic Glasses, Sci. Technol. Adv. Mater., 2017, 18(1), p 152–162.

Q. Sun, D.M. Miskovic, H. Kong, and M. Ferry, Transition from Relaxation to Rejuvenation in Ultrastable Metallic Glass Driven by Annealing, Appl. Surf. Sci., 2021, 546(4), p 149048.

S.V. Ketov, Y.H. Sun, S. Nachum, Z. Lu, A. Checchi, A.R. Beraldin, H.Y. Bai, W.H. Wang, D.V. Louzguine-Luzgin, M.A. Carpenter, and A.L. Greer, Rejuvenation of Metallic Glasses by Non-affine Thermal Strain, Nature, 2015, 524(7564), p 200–203.

T. Ichitsubo, H. Kato, E. Matsubara, S. Biwa, S. Hosokawa, K. Matsuda, H. Uchiyama, and A. Baron, Static Heterogeneity in Metallic Glasses and its Correlation to Physical Properties, J. Non-Cryst. Solids, 2011, 357(2), p 494–500.

W. Song, X. Meng, Y. Wu, D. Cao, H. Wang, X. Liu, X. Wang, and Z. Lu, Improving Plasticity of the Zr46Cu46Al8 Bulk Metallic Glass via Thermal Rejuvenation, Sci. Bull., 2018, 63(13), p 840–844.

W. Guo, R. Yamada, and J. Saida, Rejuvenation and Plasticization of Metallic Glass by Deep Cryogenic Cycling Treatment, Intermetallics, 2018, 93, p 141–147.

W. Guo, Y. Shao, J. Saida, M. Zhao, S. Lu, and S. Wu, Rejuvenation and Plasticization of Zr-Based Bulk Metallic Glass with Various Ta Content upon Deep Cryogenic Cycling, J. Alloy. Compd., 2019, 795, p 314–318.

S.V. Ketov, A.S. Trifonov, Y.P. Ivanov, A.Y. Churyumov, A.V. Lubenchenko, A.A. Batrakov, J. Jiang, D.V. Louzguine-Luzgin, J. Eckert, J. Orava, and A.L. Greer, On Cryothermal Cycling as a Method for Inducing Structural Changes in Metallic Glasses, NPG Asia Mater., 2018, 10(4), p 137–145.

C.Y. Li, X.L. Li, Z.X. Zhao, F.P. Zhu, and Y.C. Zhao, Effect of Peak Loads and Cooling Rates on Creep Behavior of Zr-Based Bulk Metallic Glass, J. Non-Cryst. Solids, 2019, 522, p 119596.

C.Y. Li, J.F. Yin, J.Q. Ding, F.P. Zhu, F. Xu, Y.C. Zhao, and S.Z. Kou, A Thermal Processing Map of a ZrCuNiAlEr Bulk Metallic Glass in the Supercooled Liquid Region, J. Mater. Sci., 2019, 54(9), p 7246–7255.

C.Y. Li, F.P. Zhu, J.Q. Ding, J.F. Yin, Z. Wang, Y.C. Zhao, and S.Z. Kou, Investigation on Creep Behavior of Zr-Based Bulk Metallic Glass by Nanoindentation, Rare Met. Mater. Eng., 2020, 49(10), p 3353–3360.

A.J. Drehman and A.L. Greer, Kinetics of Crystal Nucleation and Growth in Pd40Ni40P20 Glass, Acta Metall., 1984, 32(3), p 323–332.

S. Cheng, C. Wang, M. Ma, D. Shan, and B. Guo, Mechanism for Microstructural Evolution Induced by High Temperature Deformation in Zr-Based Bulk Metallic Glasses, J. Alloy. Compd., 2016, 676, p 299–304.

W. Guo, Y.M. Shao, M. Zhao, S.L. Lü, and S.S. Wu, Varying the Treating Conditions to Rejuvenate Metallic Glass by Deep Cryogenic Cycling Treatment, J. Alloy. Compd., 2020, 819, p 152997.

W. Dmowski, C. Fan, M.L. Morrison, P.K. Liaw, and T. Egami, Structural Changes in Bulk Metallic Glass after Annealing Below the Glass-Transition Temperature, Mater. Sci. Eng. A Struct., 2007, 471(1–2), p 125–129.

J.W. Lv, C. Wei, S. Zhang, Z.L. Shi, H.R. Zhang, X.Y. Zhang, and M.Z. Ma, Microstructure and Mechanical Behavior Evolution of Ti-Based Bulk Metallic Glass Induced by Sub-Tg Isothermal Annealing, J. Alloy. Compd., 2021, 900, p 163300.

M.C. Li, H.M. Guan, S. Yang, X. Ma, and Q. Li, Minor Cr Alloyed Fe-Co-Ni-P-B High Entropy Bulk Metallic Glass with Excellent Mechanical Properties, Mater. Sci. Eng. A, 2021, 805, p 140542.

X.Y. Wang, P. Gong, and L. Deng, Sub-Tg Annealing Effect on the Kinetics of Glass Transition and Crystallization for a Ti-Zr-Be-Fe Bulk Metallic Glass, J. Non-Cryst. Solids, 2017, 473, p 132–140.

J.H. Luan, W.W. Zhu, G.L. Zhang, Q. Liu, W. Xun-Li, and B.L. Shen, Atomic-Scale Heterogeneity in Large-Plasticity Cu-Doped Metallic Glasses, J. Alloy. Compd., 2019, 798, p 517–522.

X.L. Ji, J. **, F. Tian, J.H. Zhao, Y.T. Zhang, C.Y. Yan, and L. Fu, Effect of Cyclic Cryogenic Treatment on Tribological Performance of Fe-Based Amorphous Coatings in Air and in 3.5% NaCl Solution, J. Non-Cryst. Solids., 2022, 583, p 121471.

Acknowledgments

This research was supported by the National Natural Science Foundation of China (Grant No. 52261032, 51861021, 51661016, 51971103), Science and Technology Plan of Gansu Province (Grant No. 21YF5GA074, 20YF8GA052), Public Welfare Project of Zhejiang Natural Science Foundation (Grant No. LGG22E010008), and Key Research Program of Education Department of Gansu Province (Grant No. GSSYLXM-03)

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

We declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work, and there is no professional or other personal interest of any nature or kind in any product, service, and/or company that could be construed as influencing the position presented in, or the review of, the manuscript entitled.

Ethical Approval

The authors declare that the experiments comply with the current laws of the country in which we performed.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhao, Z., Li, C., Liu, Y. et al. Rejuvenation and Malleability Enhancement of Zr-Based Metallic Glass by Sub-Tg Annealing and Cryogenic Thermal Cycle Treatment. J. of Materi Eng and Perform 32, 8430–8440 (2023). https://doi.org/10.1007/s11665-022-07723-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07723-2